Custom Industrial Cable Assemblies

Modern factories, automation lines, and industrial equipment all run on reliable cable assemblies.

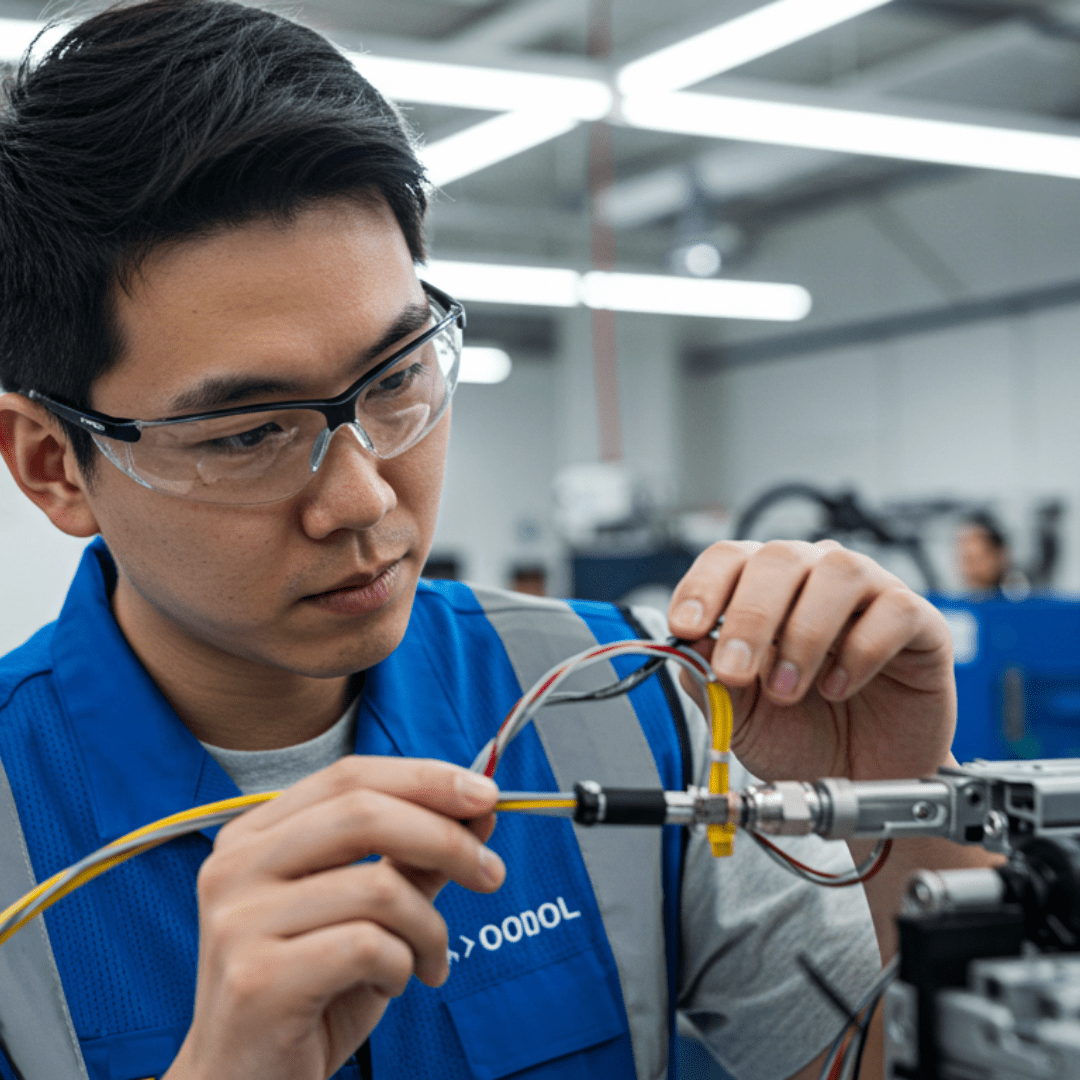

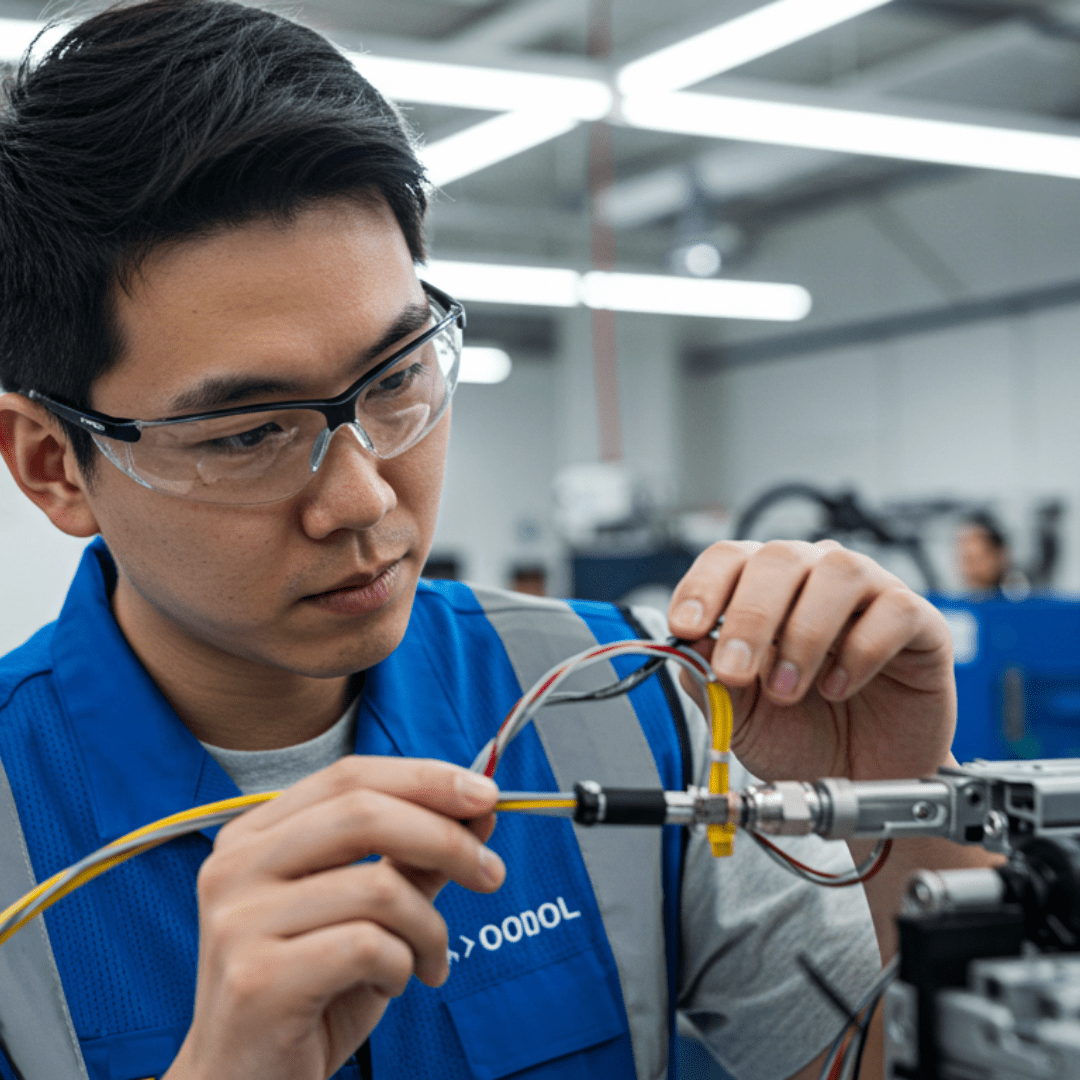

OurPCB engineers test every cable assembly to handle extreme heat or cold, chemical splashes, constant vibration, and more. Need power and data lines for heavy machinery? We’ll build exactly what your operation needs, from Ethernet cables to control harnesses.

What are Industrial Cable Assemblies?

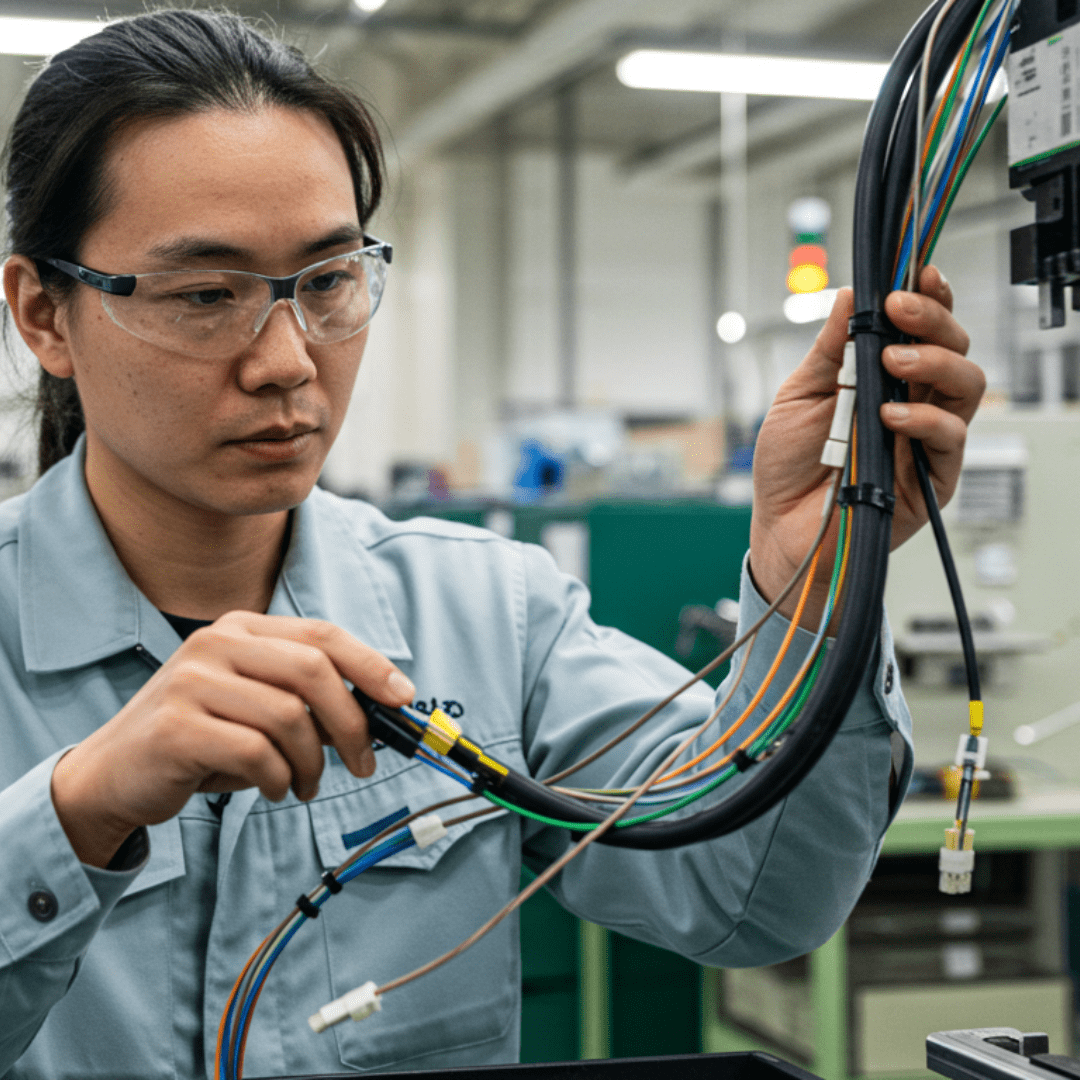

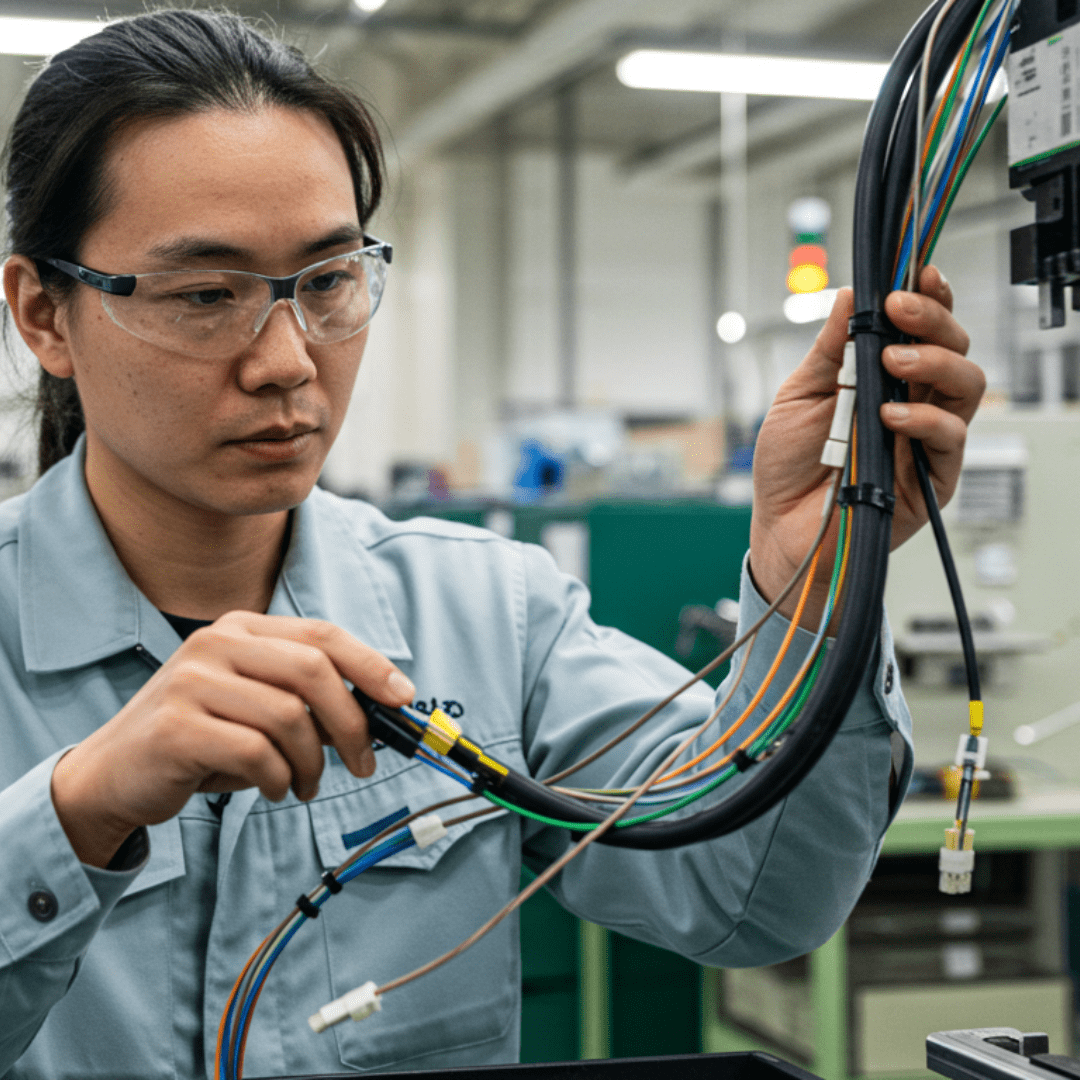

Industrial cable assemblies are organized groups of wires bundled together for specific industrial applications. These assemblies transmit power, data signals, and control commands throughout equipment and systems.

Unlike standard cables, industrial versions differ in specialized materials, strain reliefs, and durable connectors. Built to IPC/WHMA-A-620 standards, they resist vibration, moisture, temperature extremes, and EMI.

Manufacturing facilities rely on these assemblies to connect control systems, sensors, actuators, and motors. The global cable assembly market reached 185 billion USD in 2025, driven by industrial automation, electric vehicles, and data center growth.

What are the Benefits of Industrial Cable Assemblies?

- Eliminates field wiring errors through pre-assembly

- Resists temperatures from -40 °C to 125 °C and harsh chemicals

- Provides EMI shielding and integrated strain relief

- Color-coded, modular design cuts installation time by 80%

- Quick-swap capability minimizes system downtime

- 25-35% cost savings through bulk purchasing

Superior Field Reliability

- IP67-rated connectors resist complete dust ingress and withstand water immersion up to 1 m for 30 minutes.

- Marine-grade insulation materials provide chemical resistance against fertilizers, pesticides, and fuel exposure.

Extended Equipment Lifespan

- Temperature-resistant components function reliably from -40 °C to 105 °C, preventing heat damage in engine compartments.

- Reinforced strain relief and secure terminal connections prevent failures from constant diesel engine vibration.

Simplified Troubleshooting

- Color-coded wiring with clear detail reduces diagnostic time by up to 60%.

- Comprehensive documentation includes wiring diagram specifications specific to your tractor model.

Customization Options

- Exact-fit design ensures perfect compatibility with your specific Farmall or Cub Cadet restoration.

- Additional capacity options accommodate future implements or aftermarket electrical accessories you may add later.

Why Choose OurPCB for Cable Assemblies

OurPCB brings precision manufacturing expertise to wire harness production, delivering quality across all connectivity solutions.

- Automated processing: 30-8 AWG with monitored crimping

- 360° shield continuity for EMI protection

- 10-15 day standard lead time, expedited options available

- Automated electrical testing on all assemblies

- Environmental stress validation (temperature cycling, humidity, vibration)

- Full documentation and traceability

- Design optimization for performance

- 5-7 day prototype turnaround

- Scalable from prototype to production

Our Custom Wiring Harness Features

ROHS-Compliant Materials

Every harness uses certified, safe materials that protect both people and the planet. We ensure your products meet global environmental regulations effortlessly.

Connectors for Every Need

We carry an extensive selection of premium connectors from Tyco, AMP, Delphi, Molex, JAE, JST, and more. No matter how specialized your needs are, we have the right fit.

Custom Materials and Coverings

We design harnesses with targeted protection against abrasion, oil, extreme temperatures, or moisture. Pick from PVC, nylon, XLPE, rubber, braided sleeving, heat shrink tubing, and other protective options.

Variable Wire Options

We supply wires in different thicknesses and precise lengths tailored to your project. Custom sizing eliminates excess while maintaining peak electrical performance.

Across Many Industries

Our harnesses power equipment in automotive, aerospace, medical, industrial, and countless other sectors.

Millions of business and innovators use OurPCB

Our Custom Wiring Harness Process

Fast, free, and includes a production timeline

Our engineers create your design schematic and select the right materials

We’ll manufacture a high-quality prototype within 7 days

The prototype goes through various functionality and stress tests

Cutting, stripping, and assembly to the highest standard

After final testing and packaging, your custom wiring harnesses are delivered

Technical Capabilities

Our facility combines automated production with skilled technicians. Wire processing systems handle conductors with cutting tolerances within ±1 mm and strip length control to ±0.5 mm. We use force-monitored crimping for gas-tight electrical connections, processing automotive-grade, industrial, and MIL-spec connector types, including D-sub and circular formats.

Shielding application achieves greater than 90% coverage for optimal EMI protection. We apply jackets through extrusion or braiding, selecting materials based on chemical resistance, flexibility, and temperature ratings. Custom overmolding provides strain relief and environmental sealing with IP67 and IP68 ratings.

We terminate coaxial cable assemblies, fiber optic connections, USB interfaces, and Ethernet cables. Our supplier relationships with Amphenol, TE Connectivity, and other industry leaders ensure access to high-performance components. We tailor each solution to your application, whether off-the-shelf configurations or fully custom designs for compact spaces.

Assembly options include multi-conductor bundles, jumper cables with latch mechanisms, and flexible configurations for automotive, machinery, and OEM applications. Our configurator helps specify length, termination style, and connector options. We manufacture indoor and outdoor assemblies that automate your processes while reducing installation time.

Capabilities & Services

- Wire Gauge: 40AWG-120mm²

- Production Capacity: 10,000 pieces/hour

- Wire Cutting Service

- Wire Stripping Service

- Wire Marking Service

- Label Types

- Wire Ends Treatment

Custom Wire/Cable Service:

- Wire/Cable types

- Wire gauge

- Wire/Cable length

- Insulation/Jacket color

- Core numbers etc.

Custom Cable Assembly Capacities:

All kinds of cable assemblies including

- Electrical cable assembly

- Coaxial cable assembly

- Multi-core cable assembly

- Connector to board cable assembly

- Automobile communication cable assembly

- Power transmission cable assembly

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Custom Industrial Cable Assemblies FAQs

What connector types do you work with?

We integrate circular connectors (M8, M12), D-sub connectors, modular Ethernet RJ45, USB types, and MIL-spec, including MIL-C-38999 and MIL-C-5015 series. Our team recommends optimal types based on your environment and mating cycles.

What are your minimum order quantities?

We accommodate single prototype units through 10,000+ production runs. Prototype orders receive the same quality standards as high-volume production with flexible pricing.

Do assemblies include test documentation?

Every assembly includes test reports documenting continuity, insulation resistance, and dielectric test results. We provide certificates of conformance and material certifications for traceability.