Industrial Wire Harness Manufacturer | Made for Industrial Applications

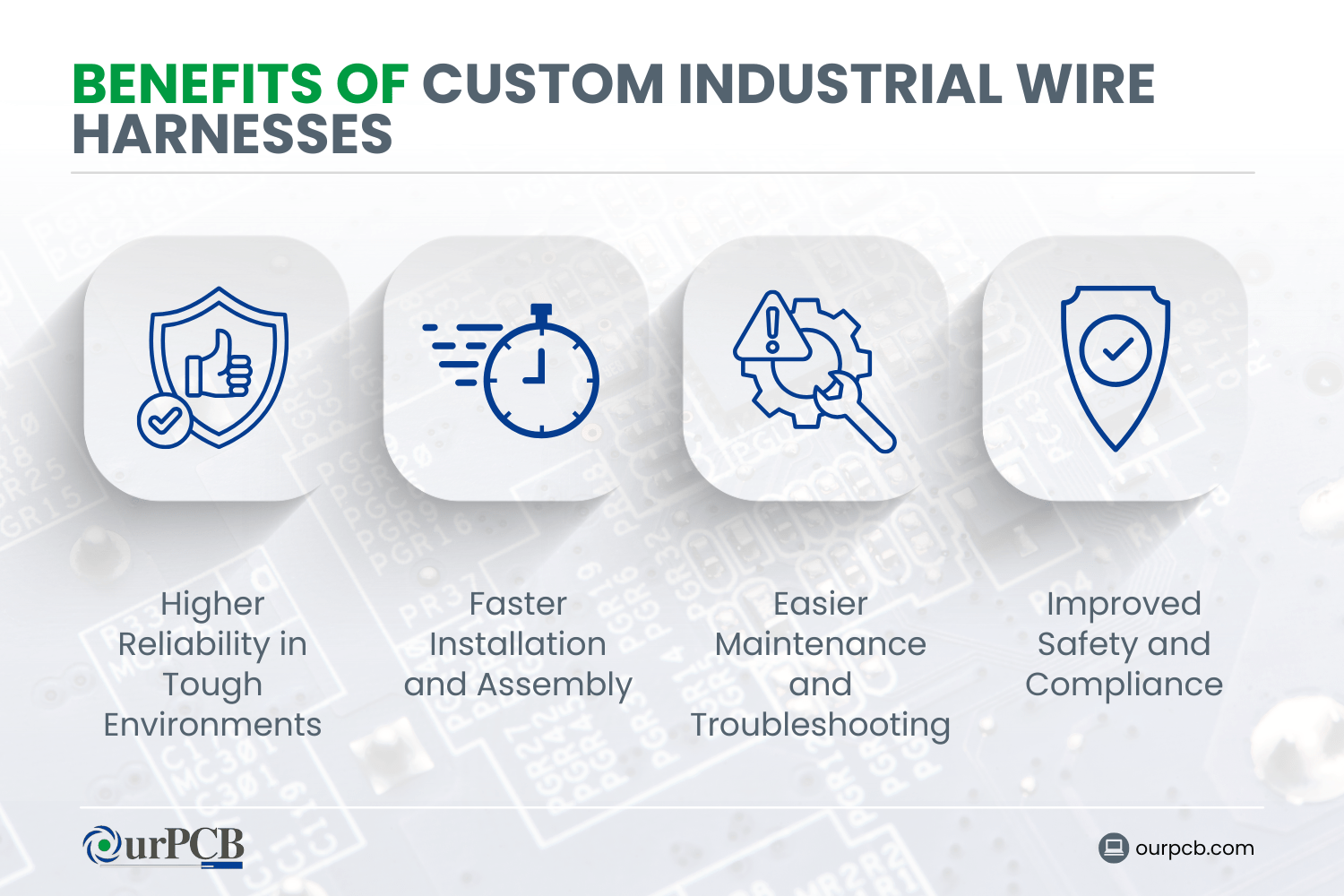

OurPCB designs and builds custom assemblies for factory automation, robotics, heavy machinery, renewable energy, and process control systems. We offer you over 10,000 square feet, ISO 9001 and IATF 16949-certified harness facility that processes 30 to 4 AWG conductors for environments from −65 °C to +200 °C.

As an industrial wire harness manufacturer, we engineer each harness to withstand continuous vibration and mechanical stress in 24/7 production lines and mobile equipment. Every assembly is built to IPC/WHMA-A-620 workmanship standards, helping keep your equipment online and maintenance teams ahead of cardinal failures.

What are Industrial Wire Harnesses

Industrial wire harnesses are wiring that directs power, signals, and data between machines and electronic systems. The harness bundles together wires, providing coverings for the conductors.

Wire harnesses are a staple of industrial production. They have a place in motor drives, conveyor systems, PLC and control cabinets, sensors, actuators, field devices, HMIs, operator panels, and safety circuits – and more!

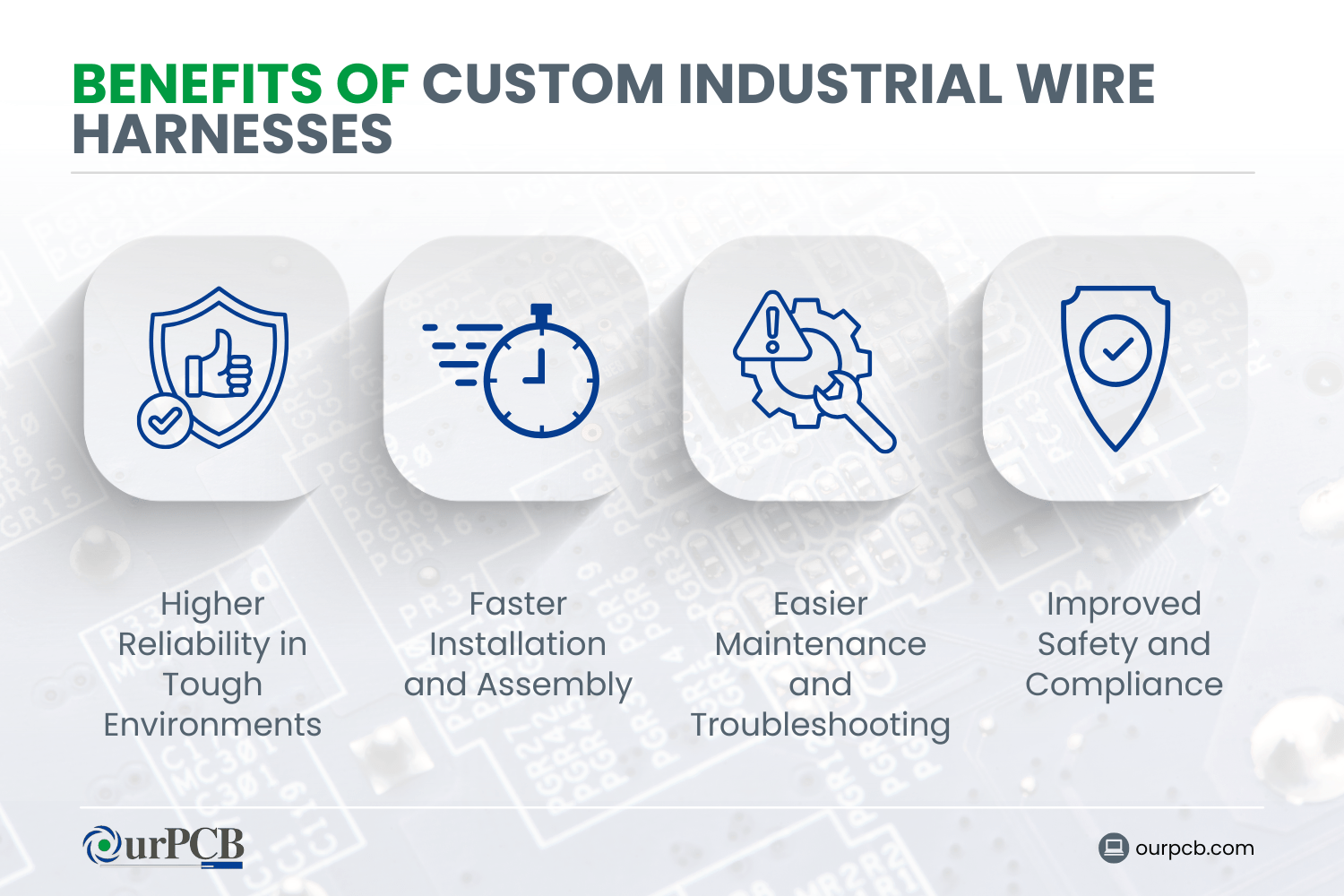

What are the Benefits of Custom Industrial Wire Harnesses?

The benefits of custom industrial wire harnesses are that they improve industrial production consistency by taking advantage of engineered routing, strain relief, and industrial-grade materials for harsh environments. If you use standardized industrial wiring, you’ll be able to enjoy clearly labeled harnesses, speedy troubleshooting, enable modular repairs, and support safety compliance.

- Engineered routing and strain relief reduce conductor fatigue and broken terminations

- Industrial-grade insulation, jacketing, and grommets resist oils, coolants, abrasion, and UV

- Shielding and grounding strategies minimize electrical noise and signal interference

- Pre-labeled connectors and wires reduce wiring time on the factory floor

- Harnesses arrive panel- or machine-ready, with lengths, terminations, and branches pre-defined

- Reduced need for on-site crimping, cutting, and troubleshooting

- Clear identification, color codes, and labeling support quicker fault-finding. Modular harness sections allow partial replacement instead of full rewiring

- Standardized harness designs simplify technician training and spare parts stocking

- Designs aligned with relevant industry standards and best practices

- Proper creepage, clearance, and insulation selections for the application

- Consistent build quality across all units, reducing wiring-related safety risks

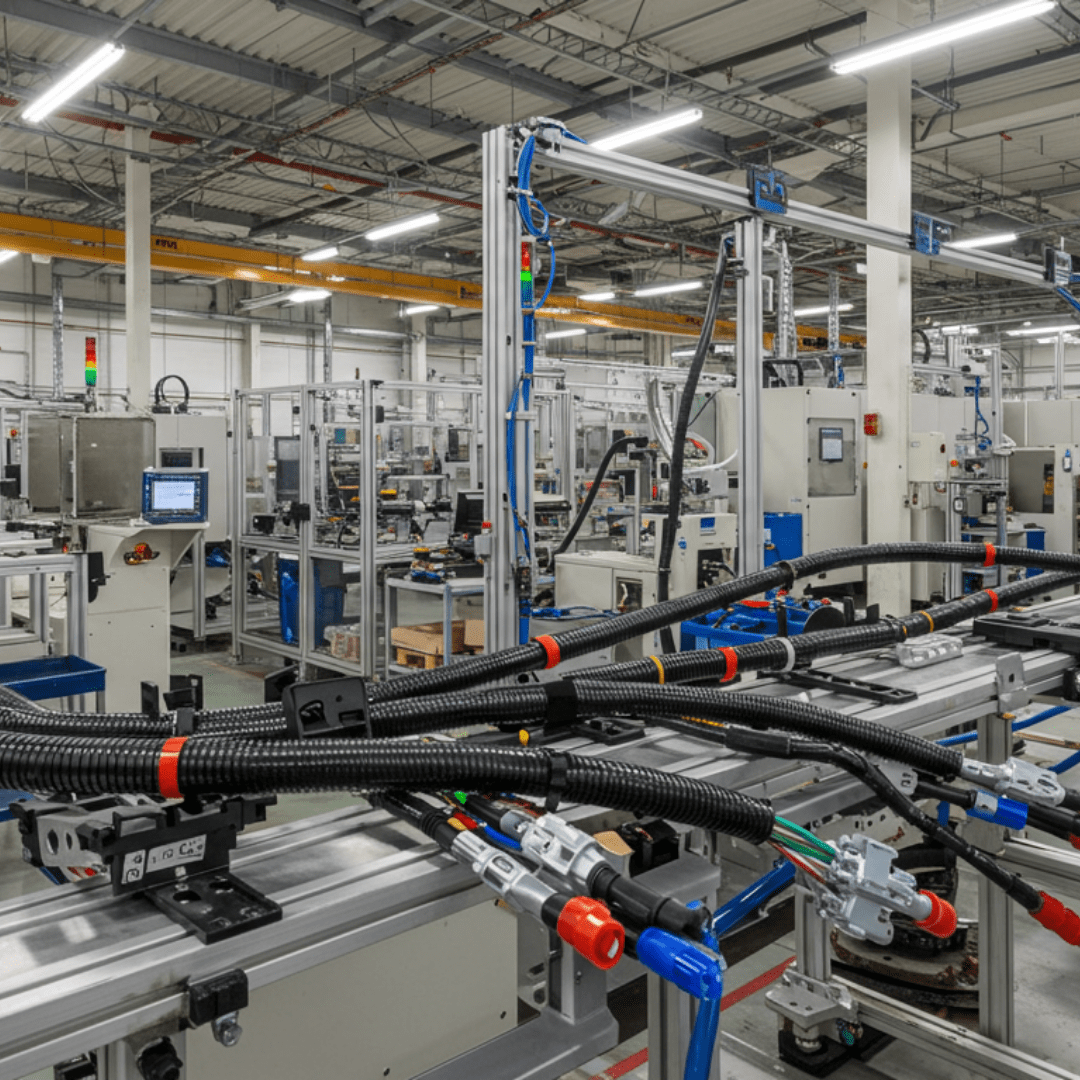

Superior Field Reliability

- IP67-rated connectors resist complete dust ingress and withstand water immersion up to 1 m for 30 minutes.

- Marine-grade insulation materials provide chemical resistance against fertilizers, pesticides, and fuel exposure.

Extended Equipment Lifespan

- Temperature-resistant components function reliably from -40 °C to 105 °C, preventing heat damage in engine compartments.

- Reinforced strain relief and secure terminal connections prevent failures from constant diesel engine vibration.

Simplified Troubleshooting

- Color-coded wiring with clear detail reduces diagnostic time by up to 60%.

- Comprehensive documentation includes wiring diagram specifications specific to your tractor model.

Customization Options

- Exact-fit design ensures perfect compatibility with your specific Farmall or Cub Cadet restoration.

- Additional capacity options accommodate future implements or aftermarket electrical accessories you may add later.

Why Choose OurPCB as Your Industrial Wire Harness Manufacturer

- IPC-A-620-based harness manufacturing processes

- Documented work instructions and process control for repeatability

- 100% continuity checks and targeted functional testing as required

- Built exactly to your drawings, BOM, and routing requirements

- Support for design refinement to improve manufacturability and serviceability

- Flexible production for prototypes, pilot builds, and full-series production

- Dedicated prototype lines for new projects and engineering builds

- Scalable production for ongoing orders and scheduled releases

- Material and production planning aligned with your forecast and project milestones

If you also require PCB fabrication and assembly, OurPCB can integrate:

- Control PCBs, cable assemblies, and panel harnesses in one supply chain

- Pre-tested sub-assemblies for plug-and-play installation

- Consolidated logistics and documentation across PCB and harness products

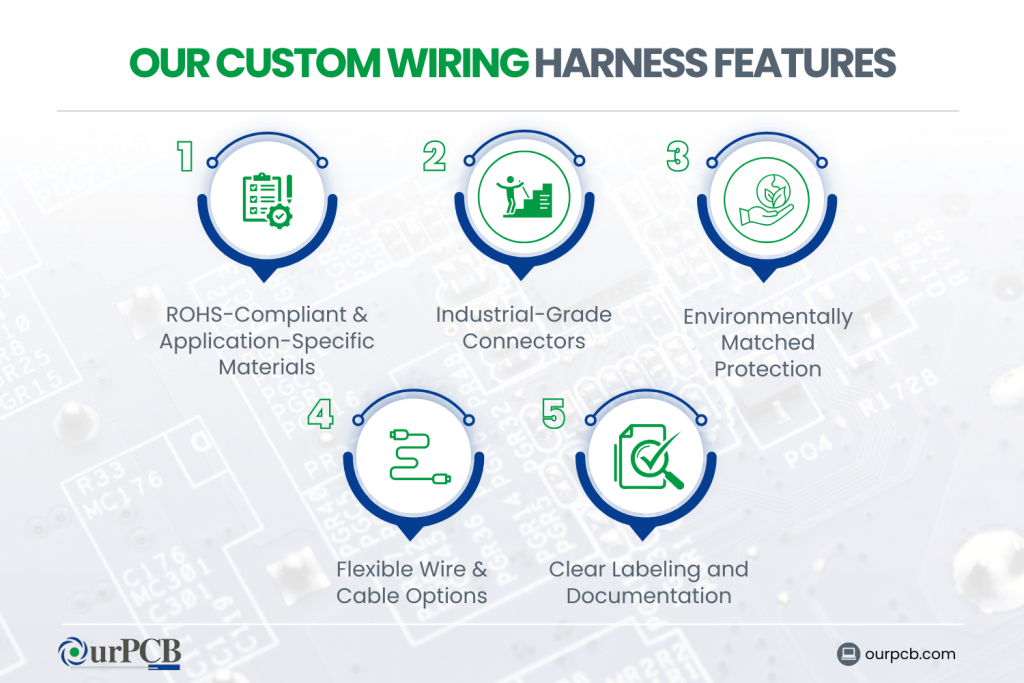

Our Custom Wiring Harness Features

ROHS-Compliant & Application-Specific Materials

- RoHS-compliant wires, terminals, and insulation options

- Flame-retardant, high-temperature, halogen-free, and chemical-resistant materials available

- Material selection guided by your environmental and regulatory requirements

Industrial-Grade Connectors

- Support for major brands and connector systems used in:

- Automation and motion control

- Industrial networking (Ethernet, fieldbus, etc.)

- Power distribution and control panels

- Custom overmolded connectors and strain reliefs available for high-stress locations

Environmentally Matched Protection

- Options for abrasion-resistant loom, corrugated tubing, and conduit

- Braided sleeving, heat shrink, and custom over-braids for additional protection

- Gaskets, boots, and seals for IP-rated enclosures and outdoor applications

Flexible Wire & Cable Options

- Multiple conductor sizes and types for power, control, and signal lines

- Multi-core, shielded, twisted pair, and hybrid cable constructions

- Custom lengths and breakouts tailored to your machine layout

Clear Labeling and Documentation

- Wire numbering, color coding, barcodes, and customer-specific ID systems

- Harness drawings, pinout tables, and test reports supplied as required

- Documentation that supports both production and field service teams

Millions of business and innovators use OurPCB

Our Custom Wiring Harness Process

Fast, free, and includes a production timeline

Our engineers create your design schematic and select the right materials

We’ll manufacture a high-quality prototype within 7 days

The prototype goes through various functionality and stress tests

Cutting, stripping, and assembly to the highest standard

After final testing and packaging, your custom wiring harnesses are delivered

Technical Capabilities

OurPCB runs climate-controlled harness facilities for repeatable quality. Our automated equipment processes 40 AWG to 120 mm² conductors with about ±1 mm cutting and ±0.5 mm strip tolerance. We work with tinned or bare copper, using PVC, nylon, XLPE, rubber, braided sleeving, and heat-shrink for protection.

You can expect harness designs to cover low-voltage control and signal plus power circuits up to 600 V and −40 °C to +125 °C. The shielded bundles with braid or foil manage EMI, while overmolding and grommets provide strain relief and IP67–IP68 sealing.

We provide wire harness assemblies to IPC/WHMA-A-620 under ISO 9001 and IATF 16949. We also convert loose field wiring into organized harnesses and manage design changes so documentation and production stay synchronized.

Capabilities & Services

- Wire gauge range of 40 AWG to 120 mm² conductors for control, signal, and power.

- Throughput up to ~10,000 harnesses per hour across automated cutting, stripping, and crimping lines.

- Wire cutting and stripping services with tight length and strip-length tolerances for repeatable assembly.

- Wire and cable marking, including IDs, part numbers, and date codes to support installation and service.

- Multiple label formats such as heat-shrink, adhesive labels, and customer-specified markers.

- Wire-end treatments including crimped terminals, soldered terminations, and connectorization to industrial, circular, and board-mount interfaces.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Industrial Wire Harness Manufacturer FAQs

What exact information do you need to quote an industrial wire harness project?

In order to prepare a quote, we’d typically need your harness drawings. In addition to that, a BOM with connectors, wire types, and accessories. We also require expected quantities and any specific testing, labeling, or certification requirements – these all contribute to the cost we outline for your quotation.

Can you help improve or standardize our existing harness designs?

Yes, absolutely. Our proficient and savvy engineering team will be more than happy to review your existing harnesses and suggest ways to save on costs for your designs. We can also optimize routing and labeling to speed installation and make service easier if necessary.

What lead times should we expect for industrial harness manufacturing?

Our lead times depend on several factors, like your harness complexity, which materials are available to us, and how much you’re ordering. Generally, prototypes and small trials can be made quickly after design approval, but forecasts, blanket orders, and phased deliveries need extra attention and time.