Complex Wire Harness Manufacturing for When Simple Won't Cut It

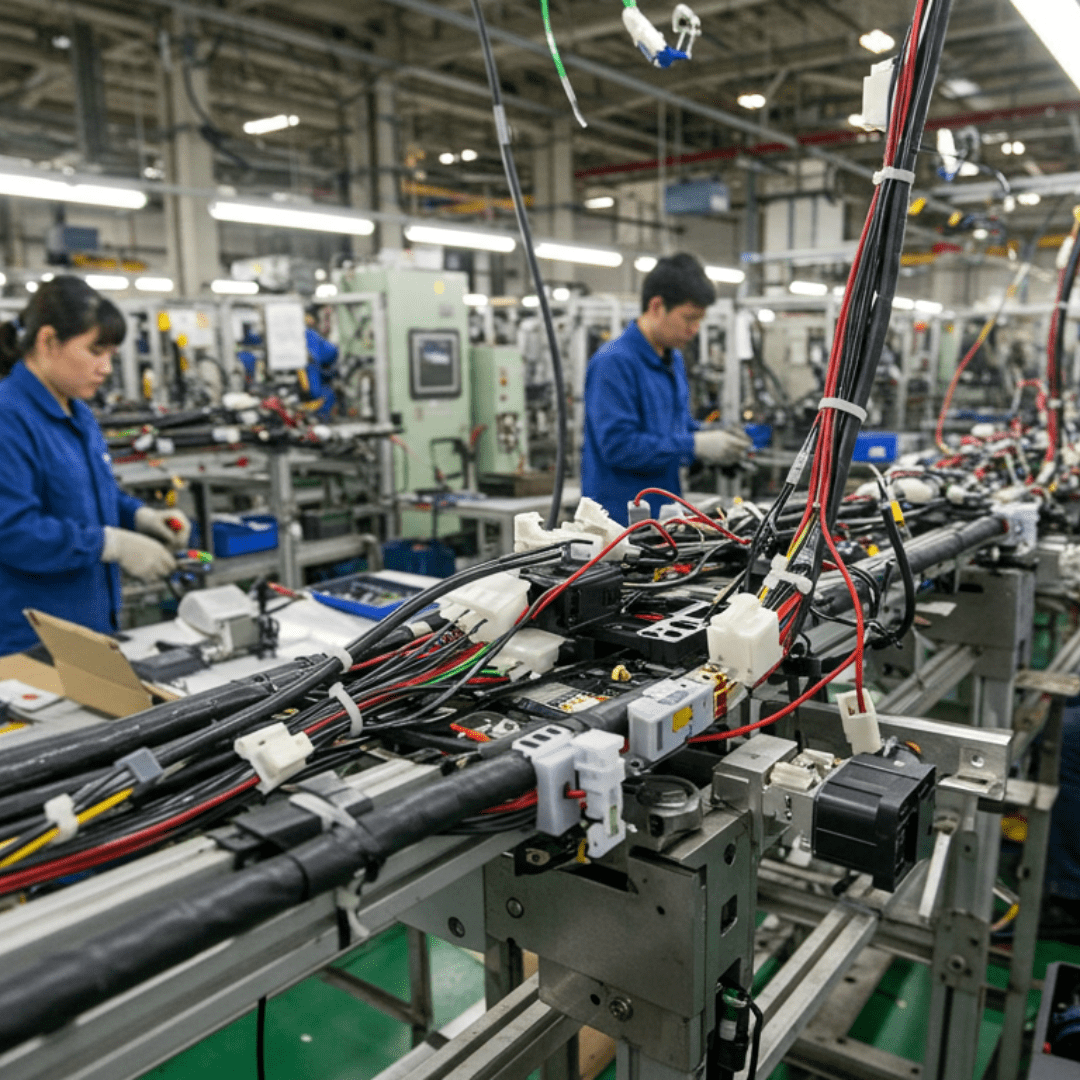

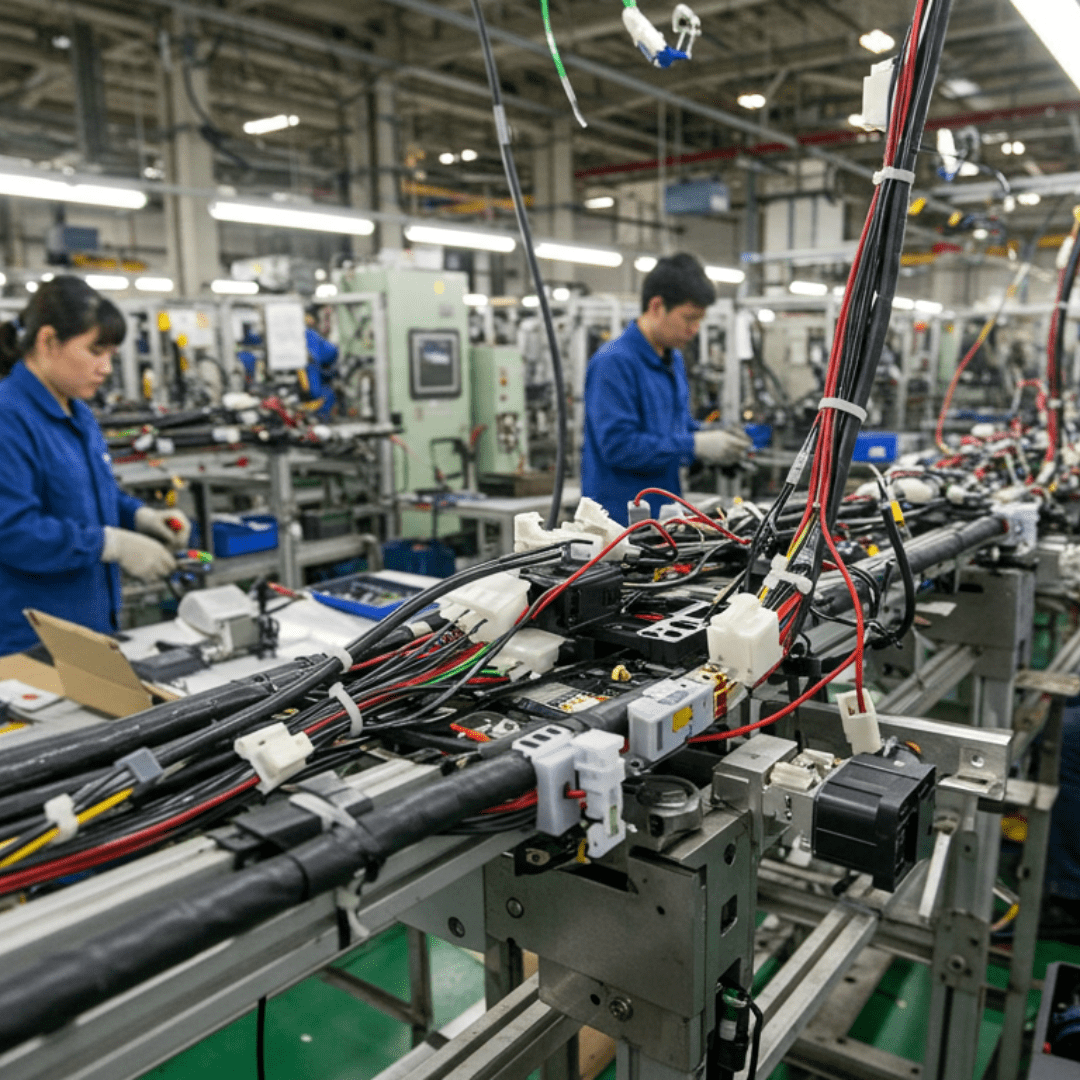

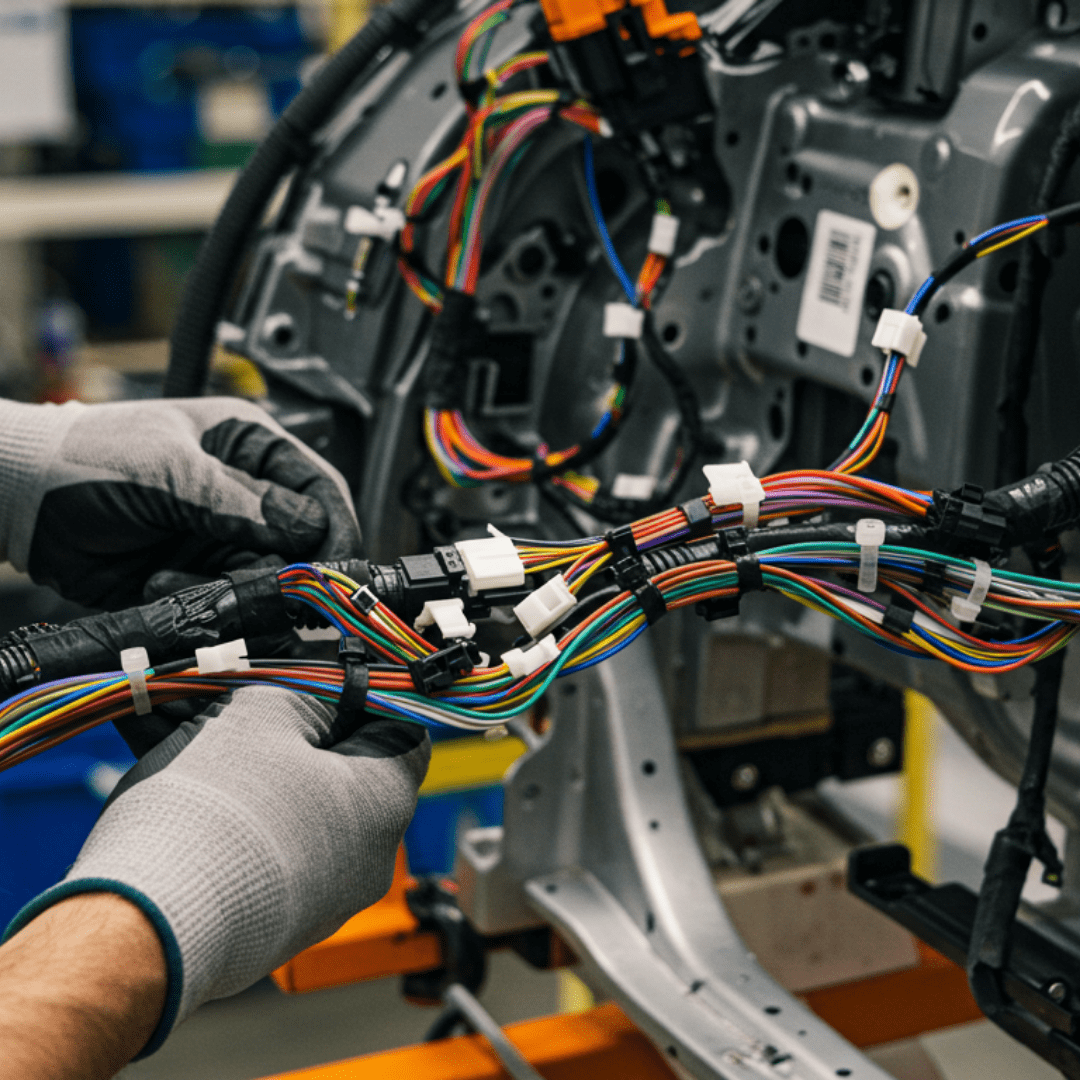

We manufacture complex wire harnesses for industries that can’t afford failures, such as automotive, aerospace, industrial machinery, and high-end electronics. Our process mixes advanced automation with hands-on expertise, so every harness meets your exact electrical and mechanical specs.

The wire harness industry is exploding right now. With that kind of growth comes plenty of challenges, but we’ve got the experience and quality controls to help you stay ahead of it all.

What is Complex Wire Harness Manufacturing?

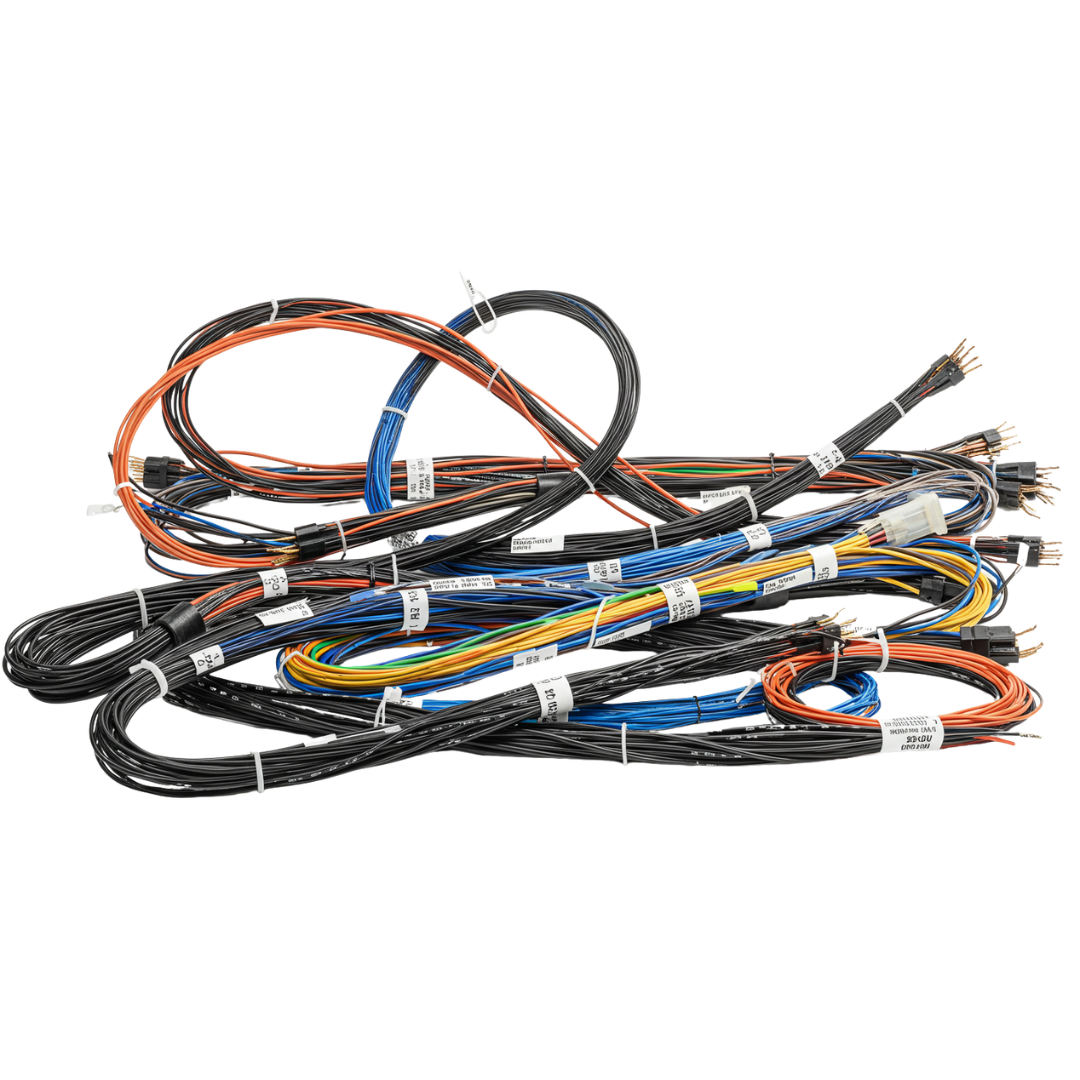

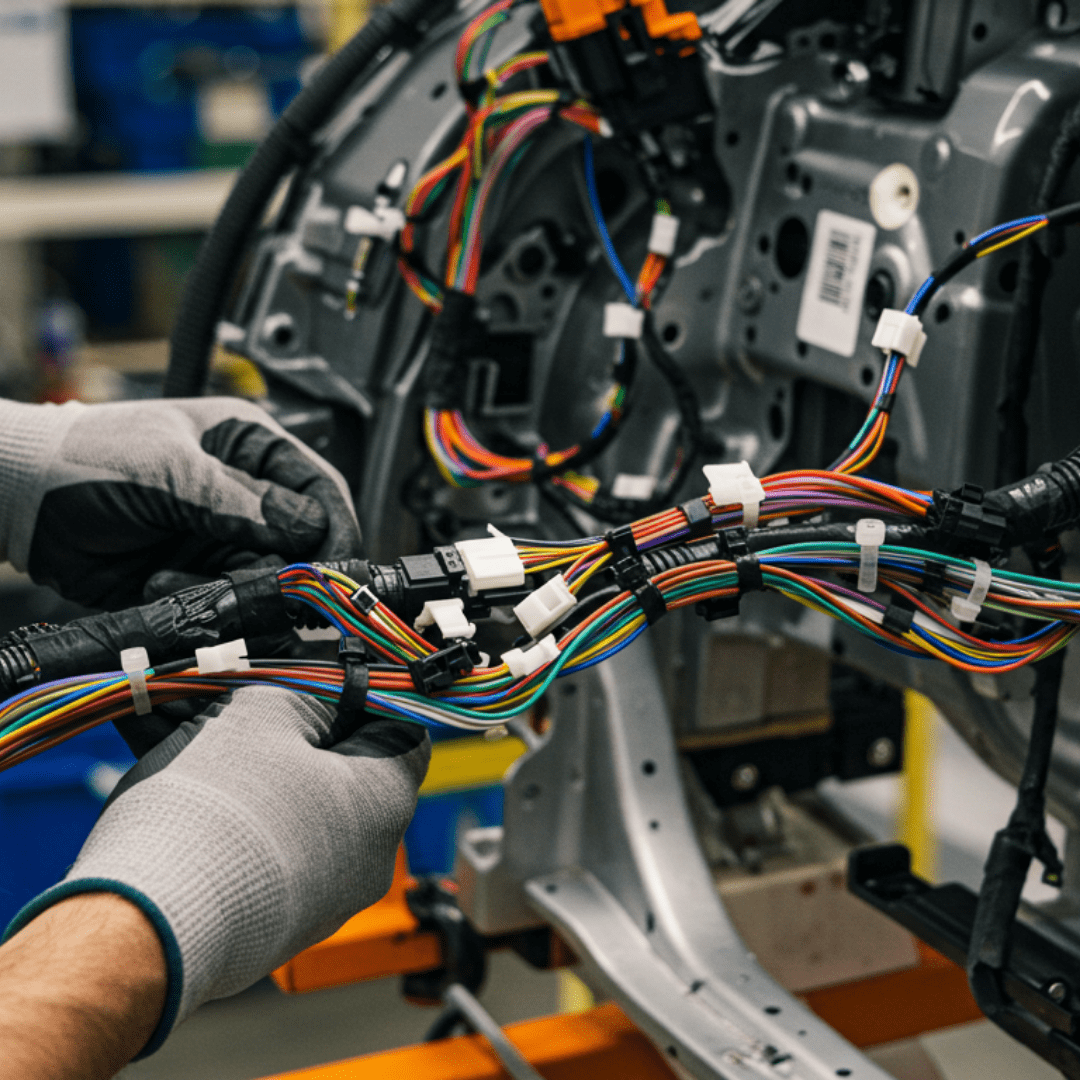

Complex wire harness manufacturing assembles multiple wires, cables, connectors, and terminals into organized bundles. These harnesses transmit electrical signals and power throughout electronic systems. The complexity comes from routing paths that avoid interference and diverse wire specifications requiring different handling.

Modern harnesses integrate shielding for electromagnetic protection and insulation layers for safety, and labeling systems for traceability. Manufacturing requires sophisticated equipment, automated cutting and crimping machines. Skilled technicians and comprehensive testing protocols are required.

The Benefits of Complex Wire Harness Manufacturing

- Pre-assembled harnesses arrive ready to install, cutting setup time by 50-70%

- Field technicians require less training when installing harnesses versus loose wire, reducing labor costs and streamlining operations

- Automated crimping equipment with force monitoring creates consistent connections that resist corrosion and maintain low resistance

- Protective coverings like braided sleeves and heat-shrink shield against abrasion, chemicals, and extreme temperatures

- Engineers design harnesses to follow specific routing paths that maximize available space while minimizing material costs

- Precise wire selection considers current requirements to specify the smallest gauge that safely meets electrical demands

- Each harness undergoes electrical continuity testing, insulation resistance verification, and pull testing before shipment

- Documentation systems track materials and test results for regulatory compliance with ISO/TS 16949 and IPC/WHMA-A-620 standards

Superior Field Reliability

- IP67-rated connectors resist complete dust ingress and withstand water immersion up to 1 m for 30 minutes.

- Marine-grade insulation materials provide chemical resistance against fertilizers, pesticides, and fuel exposure.

Extended Equipment Lifespan

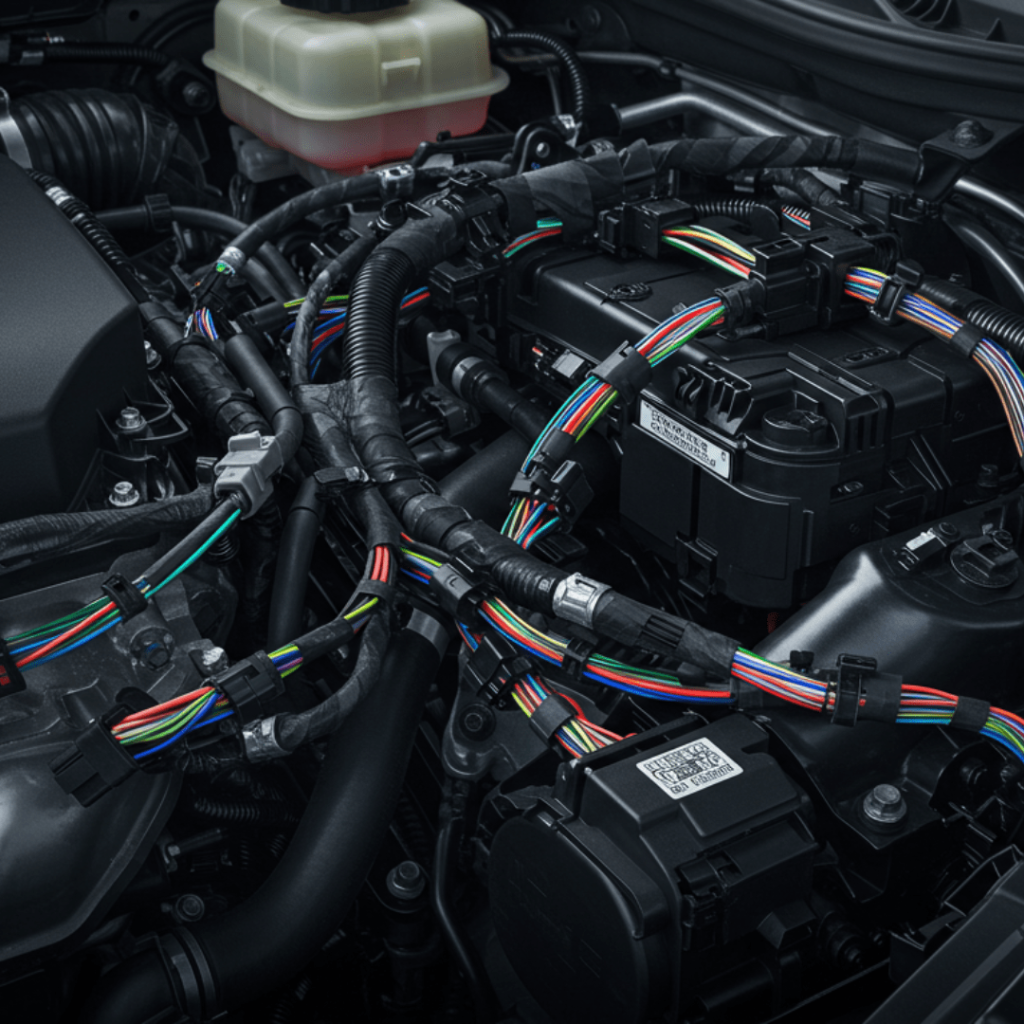

- Temperature-resistant components function reliably from -40 °C to 105 °C, preventing heat damage in engine compartments.

- Reinforced strain relief and secure terminal connections prevent failures from constant diesel engine vibration.

Simplified Troubleshooting

- Color-coded wiring with clear detail reduces diagnostic time by up to 60%.

- Comprehensive documentation includes wiring diagram specifications specific to your tractor model.

Customization Options

- Exact-fit design ensures perfect compatibility with your specific Farmall or Cub Cadet restoration.

- Additional capacity options accommodate future implements or aftermarket electrical accessories you may add later.

Why Choose OurPCB for Complex Wire Harness Manufacturing

- Our engineers use CAD software that reduces design errors by up to 50% through automated checks for routing conflicts

- Digital twin technology simulates harness performance under various conditions, predicting stress points and thermal behavior

- ISO/TS 16949 principles guide our process from incoming material inspection through final testing verification

- Environmental testing validates performance through vibration, thermal cycling, humidity exposure, and salt spray corrosion resistance

- UL and CSA certifications demonstrate electrical safety compliance across North American markets

- APQP and PPAP methodologies ensure systematic quality planning and controlled production launches with full traceability

- Streamlined quoting reduces prototype cycles by up to 30%

- Just-in-Time delivery systems align production with your schedules, minimizing inventory costs while ensuring a reliable supply

Our Custom Wiring Harness Features

ROHS-Compliant Materials

We utilize only approved, environmentally sound materials that meet international safety standards. Your projects stay compliant without compromising quality or sustainability.

Connectors for Every Need

Our supplier network includes Tyco, AMP, Delphi, Molex, JAE, JST, and numerous other trusted brands. We source exactly what your specifications demand, every time.

Custom Materials and Coverings

Whether facing abrasion, oil, heat, or water challenges, we select materials built for durability. We offer PVC, nylon, XLPE, rubber, braided sleeving, heat shrink tubing, and more protective solutions, too.

Across Many Industries

We design and build harnesses for automotive, aerospace, medical, manufacturing, and virtually any sector imaginable. Connect with us today to discuss your industry-specific challenges.

Millions of business and innovators use OurPCB

Our Custom Wiring Harness Process

Fast, free, and includes a production timeline

Our engineers create your design schematic and select the right materials

We’ll manufacture a high-quality prototype within 7 days

The prototype goes through various functionality and stress tests

Cutting, stripping, and assembly to the highest standard

After final testing and packaging, your custom wiring harnesses are delivered

Technical Capabilities

OurPCB’s facility operates advanced equipment spanning wire preparation through final testing. Automated systems maintain length tolerances within ±2 mm across gauges from AWG 32 to 535 MCM. Precision stripping removes insulation without damaging conductors.

Crimp force monitoring measures every terminal connection, enabling statistical process control. Testing infrastructure includes continuity testers for every circuit, high-voltage testers for dielectric integrity, and mechanical pull testers for retention strength. Environmental chambers simulate temperatures from -40 °C to +125 °C and humidity up to 95% relative humidity. We have a wide variety of technical capabilities for your wire harness design.

Capabilities & Services

- Wire Gauge: 40AWG-120mm²

- Production Capacity: 10,000 pieces/hour

- Wire Cutting Service

- Wire Stripping Service

- Wire Marking Service

- Label Types

- Wire Ends Treatment

Custom Wire/Cable Service:

- Wire/Cable types

- Wire gauge

- Wire/Cable length

- Insulation/Jacket color

- Core numbers etc.

Custom Cable Assembly Capacities:

All kinds of cable assemblies including

- Electrical cable assembly

- Coaxial cable assembly

- Multi-core cable assembly

- Connector to board cable assembly

- Automobile communication cable assembly

- Power transmission cable assembly

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Complex Wire Harness Manufacturing FAQs

What industries does OurPCB serve with wire harnesses?

We manufacture harnesses for automotive, aerospace, industrial, telecommunications, medical, consumer electronics, and defense applications. Each industry receives custom solutions engineered to meet specific regulatory and performance requirements across various industries.

What wire gauge ranges can you handle?

Our equipment handles wire from AWG 32 (0.03 mm²) through 535 MCM (270 mm²), covering applications from signal wiring in electronics through heavy power distribution in industrial machinery.

How does OurPCB ensure quality in complex wiring?

Every harness undergoes 100% electrical continuity testing and visual inspection, plus insulation resistance, terminal pull strength, and environmental stress validation. Our meticulous approach with strain relief, grommets, and proper cable assemblies ensures high-quality, cost-effective results that reduce maintenance and installation time.