Appliance Wire Harness Manufacturers

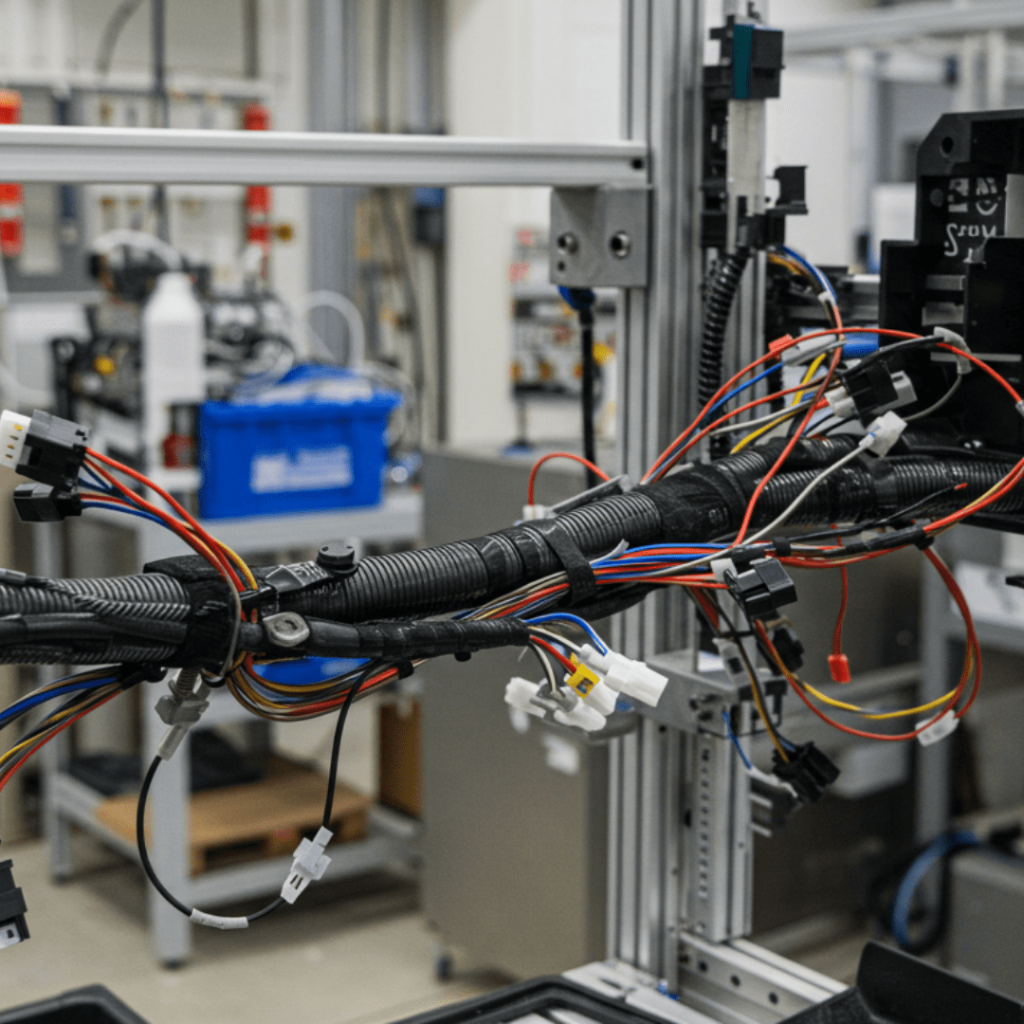

Every appliance in your home or facility depends on wiring systems that handle power distribution and signal transmission. Wire harness assemblies take what would otherwise be a mess of loose wires, cables, terminals, and connectors and organize them into engineered bundles. These are safer, easier to install, and way more reliable.

OurPCB designs and produces wiring under ISO 9001 quality standards. From prototype development to high-volume production runs, our harnesses integrate with your products.

What are Appliance Wire Harnesses?

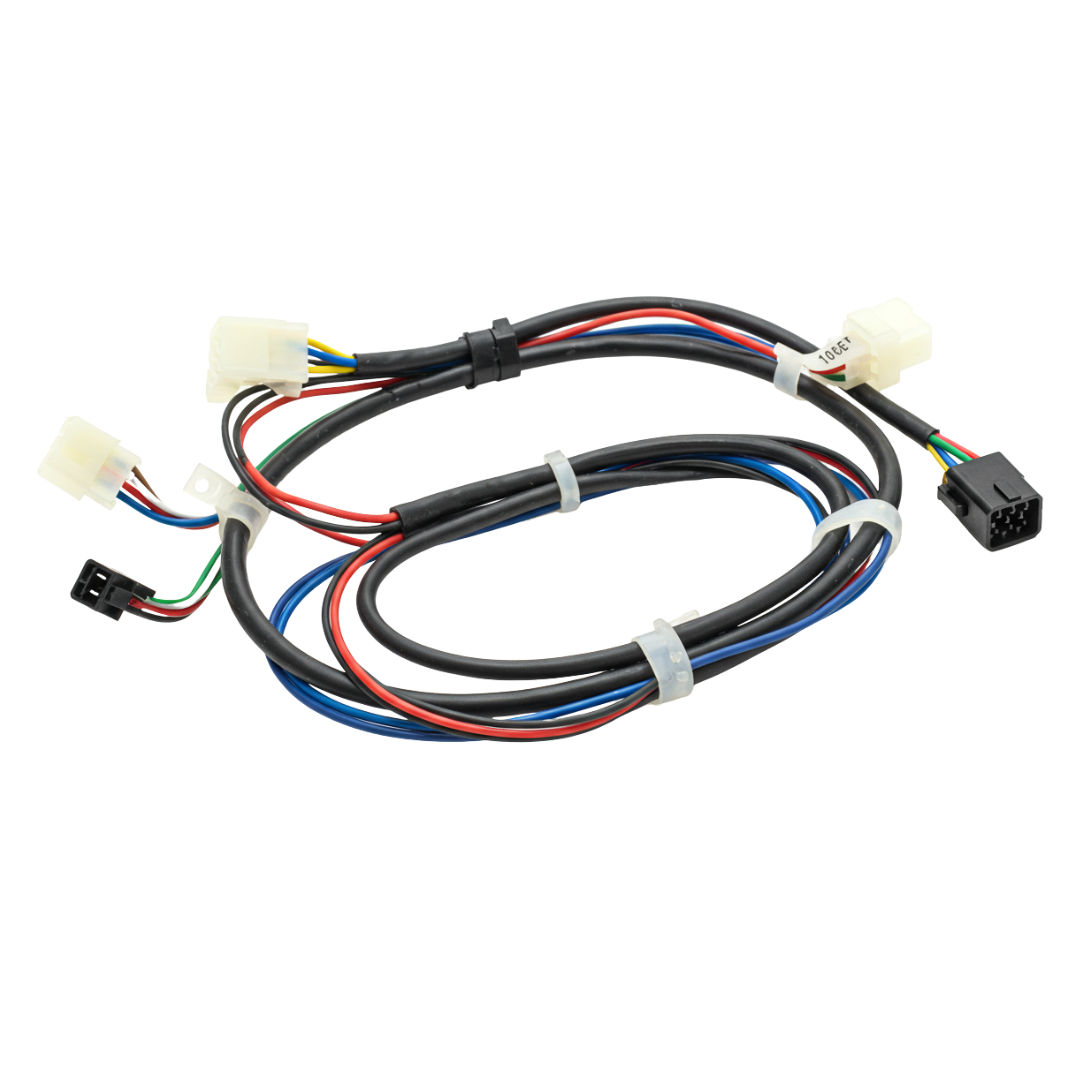

Wire harnesses are pre-assembled electrical wiring systems connecting components within electrical appliances. A cable harness organizes multiple wires and connectors into a single unit. This protects connections from abrasion and moisture while reducing assembly time during manufacturing.

Modern home appliance designs can be fridges, washing machines, air conditioners, and more. They include copper conductors, PVC insulation, MOLEX and JST connectors, plus cable ties for bundling. Each component meets specific electrical and mechanical requirements based on operating environments.

The Benefits of Appliance Wire Harnesses

- Pre-assembled harnesses cut installation time from hours to minutes during production runs

- Standardized designs eliminate routing errors and ensure consistent quality across all units

- Proper insulation and routing prevent contact with hot surfaces or moving parts

- Secure terminals maintain connections during vibration and thermal cycling in various industries

- Color-coded wire and standard connectors reduce diagnostic time

- Modular designs allow section replacement rather than complete rewiring of equipment

- Line-to-line testing catches defects before harnesses reach finished appliances

- Pull tests verify crimp strength meets force requirements for long-term durability

Superior Field Reliability

- IP67-rated connectors resist complete dust ingress and withstand water immersion up to 1 m for 30 minutes.

- Marine-grade insulation materials provide chemical resistance against fertilizers, pesticides, and fuel exposure.

Extended Equipment Lifespan

- Temperature-resistant components function reliably from -40 °C to 105 °C, preventing heat damage in engine compartments.

- Reinforced strain relief and secure terminal connections prevent failures from constant diesel engine vibration.

Simplified Troubleshooting

- Color-coded wiring with clear detail reduces diagnostic time by up to 60%.

- Comprehensive documentation includes wiring diagram specifications specific to your tractor model.

Customization Options

- Exact-fit design ensures perfect compatibility with your specific Farmall or Cub Cadet restoration.

- Additional capacity options accommodate future implements or aftermarket electrical accessories you may add later.

Why Choose OurPCB for Appliance Wire Harness Manufacturing

OurPCB combines electronics manufacturing expertise with flexible production capabilities to deliver complete electrical solutions for appliance equipment manufacturers.

- IPC/WHMA-A-620 certified production ensures every assembly meets stringent quality standards

- IATF 16949, AS9100, and RoHS compliance qualify us for aerospace and automotive projects

- In-house design team collaborates on custom solutions from initial concept through production

- Rapid prototyping service delivers functional samples within 5-10 days for validation

- Low minimum order quantities accommodate startups and prototype phases

- Seamless scaling from prototype to high-volume production eliminates vendor changes

- Statistical process controls monitor critical parameters throughout production for consistency

- Comprehensive environmental testing validates performance under real-world operating conditions

Our Custom Wiring Harness Features

ROHS-Compliant Materials

All our components meet strict safety and environmental standards. We deliver compliance-ready, eco-conscious solutions for your projects.

Connectors for Every Need

Our inventory includes top brands like Tyco, AMP, Delphi, Molex, JAE, JST, and beyond. We match the perfect connector to your unique requirements.

Your Choice of Coverings

Select from PVC, nylon, XLPE, rubber, braided sleeving, heat shrink tubing, and additional options. We help you choose the ideal protection for your setup.

Variable Wire Options

Multiple gauges and precision lengths optimize performance while minimizing material waste.

Across Many Industries

From automotive and aerospace to medical devices and heavy manufacturing, we’ve got you covered. Get in touch to explore solutions tailored to your field.

Millions of business and innovators use OurPCB

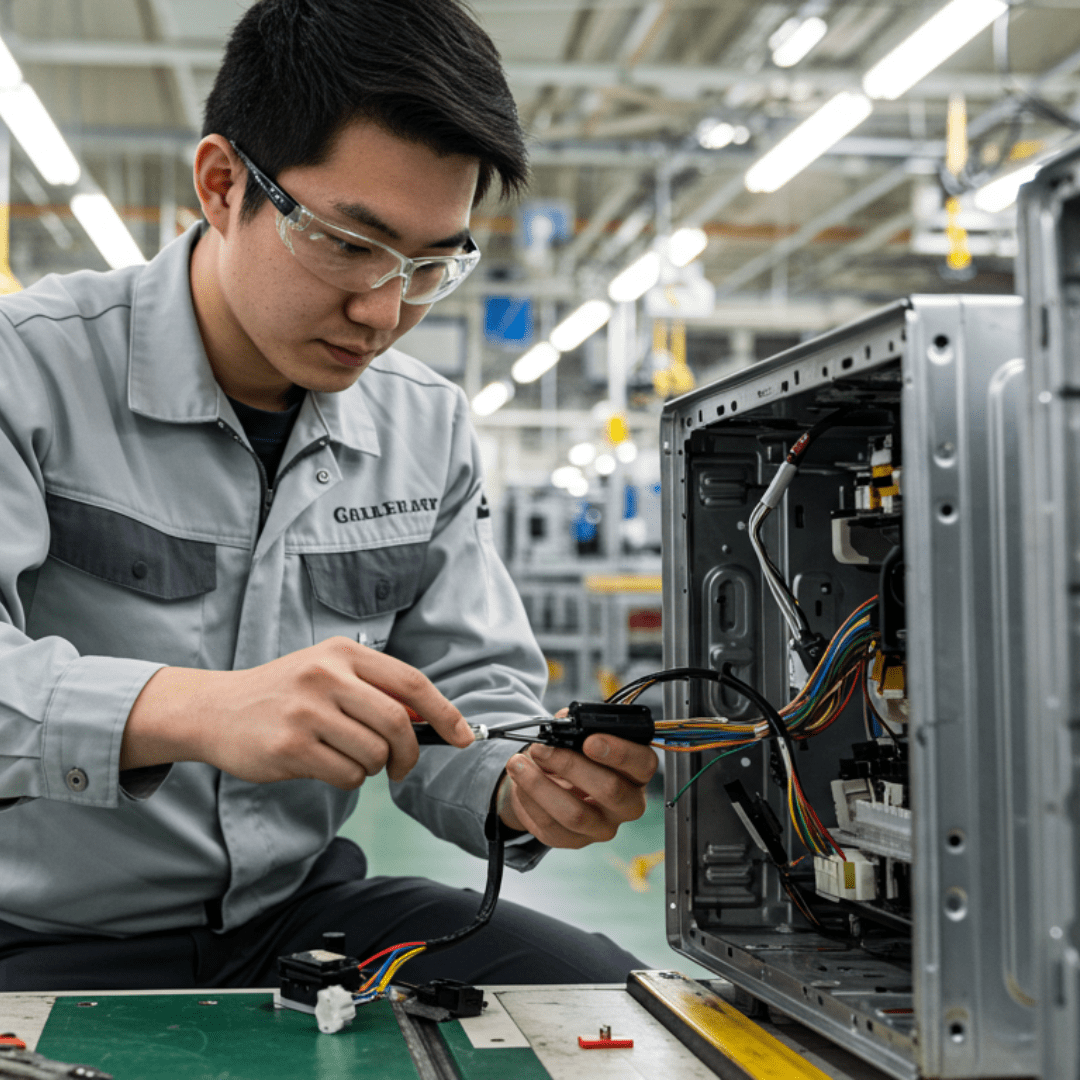

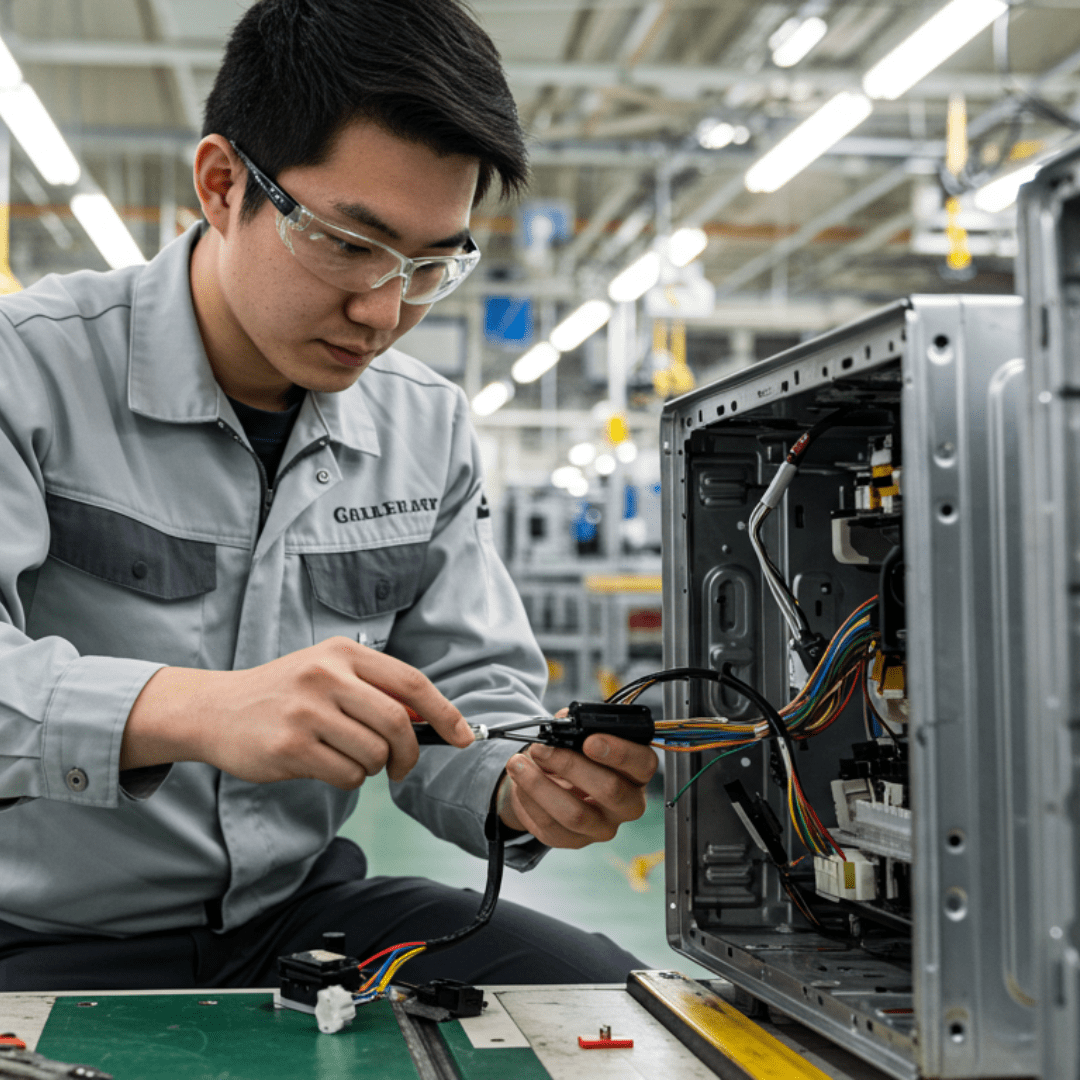

Our Custom Wiring Harness Process

Fast, free, and includes a production timeline

Our engineers create your design schematic and select the right materials

We’ll manufacture a high-quality prototype within 7 days

The prototype goes through various functionality and stress tests

Cutting, stripping, and assembly to the highest standard

After final testing and packaging, your custom wiring harnesses are delivered

Technical Capabilities

OurPCB’s automated systems handle 28 AWG to 10 AWG wire gauges for appliance applications. We have capabilities to process PVC, XLPE, and silicone insulation rated for -20 °C to +105 °C operating temperatures. Standard connectors include MOLEX, JST, AMP, and TE Connectivity housings. Custom overmolding provides moisture protection for demanding environments. Calibrated crimping tools with force monitoring ensure reliable electrical connections. Color-coded bundling accommodates both simple power circuits and complex multi-circuit control systems.

Every harness undergoes 100% electrical continuity testing. Pull force testing validates crimp strength from 20-200 N based on wire gauge. Environmental testing includes thermal cycling, humidity exposure, and vibration resistance. Production capacity ranges from 10-100 unit prototypes with 5-10 day turnaround to 5,000+ monthly assemblies. Statistical process controls maintain consistency across all production runs. Complete documentation and material traceability accompany every shipment.

Capabilities & Services

- Wire Gauge: 40AWG-120mm²

- Production Capacity: 10,000 pieces/hour

- Wire Cutting Service

- Wire Stripping Service

- Wire Marking Service

- Label Types

- Wire Ends Treatment

Custom Wire/Cable Service:

- Wire/Cable types

- Wire gauge

- Wire/Cable length

- Insulation/Jacket color

- Core numbers etc.

Custom Cable Assembly Capacities:

All kinds of cable assemblies including

- Electrical cable assembly

- Coaxial cable assembly

- Multi-core cable assembly

- Connector to board cable assembly

- Automobile communication cable assembly

- Power transmission cable assembly

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Appliance Wire Harness Manufacturers FAQs

What types of appliances use custom wire harnesses?

Wire harnesses are often essential in kitchen equipment (refrigerators, ovens, dishwashers), laundry machines, HVAC systems, and industrial appliances. Each type requires specific wire gauge, insulation, and terminal specifications based on electrical requirements.

How does OurPCB ensure quality in wire harness design?

We follow strict quality standards throughout production. Every customized wire harness undergoes electrical continuity testing and visual inspection. Our reputation as a leading manufacturer reflects our commitment to precision and product reliability.

Can you handle both prototype and production volumes?

Yes, our advanced manufacturing facility provides custom wiring solutions from prototype quantities through high-volume runs. We support rapid development cycles and scale production as your volume increases, maintaining consistent quality across all batches.