High Voltage Cable Assembly

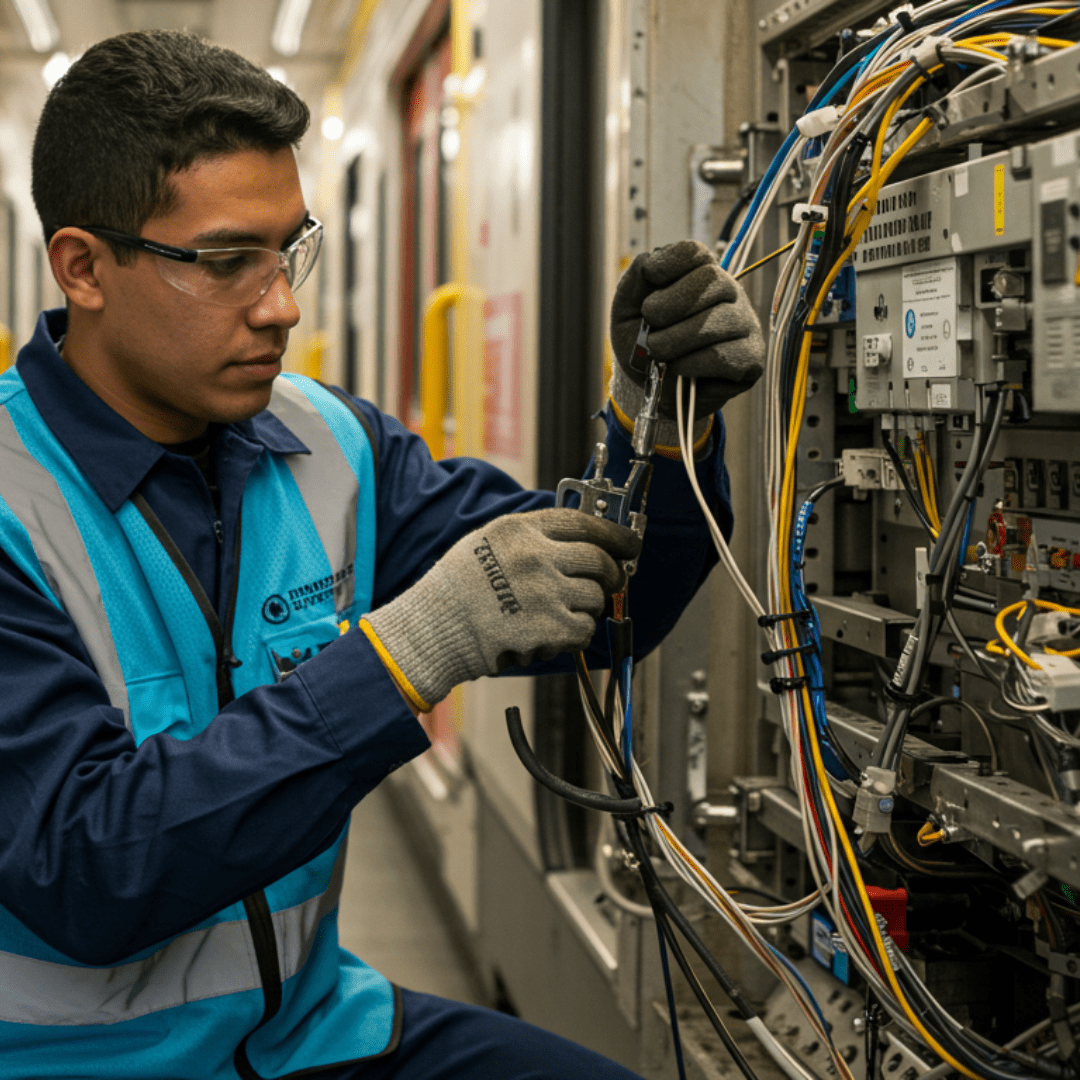

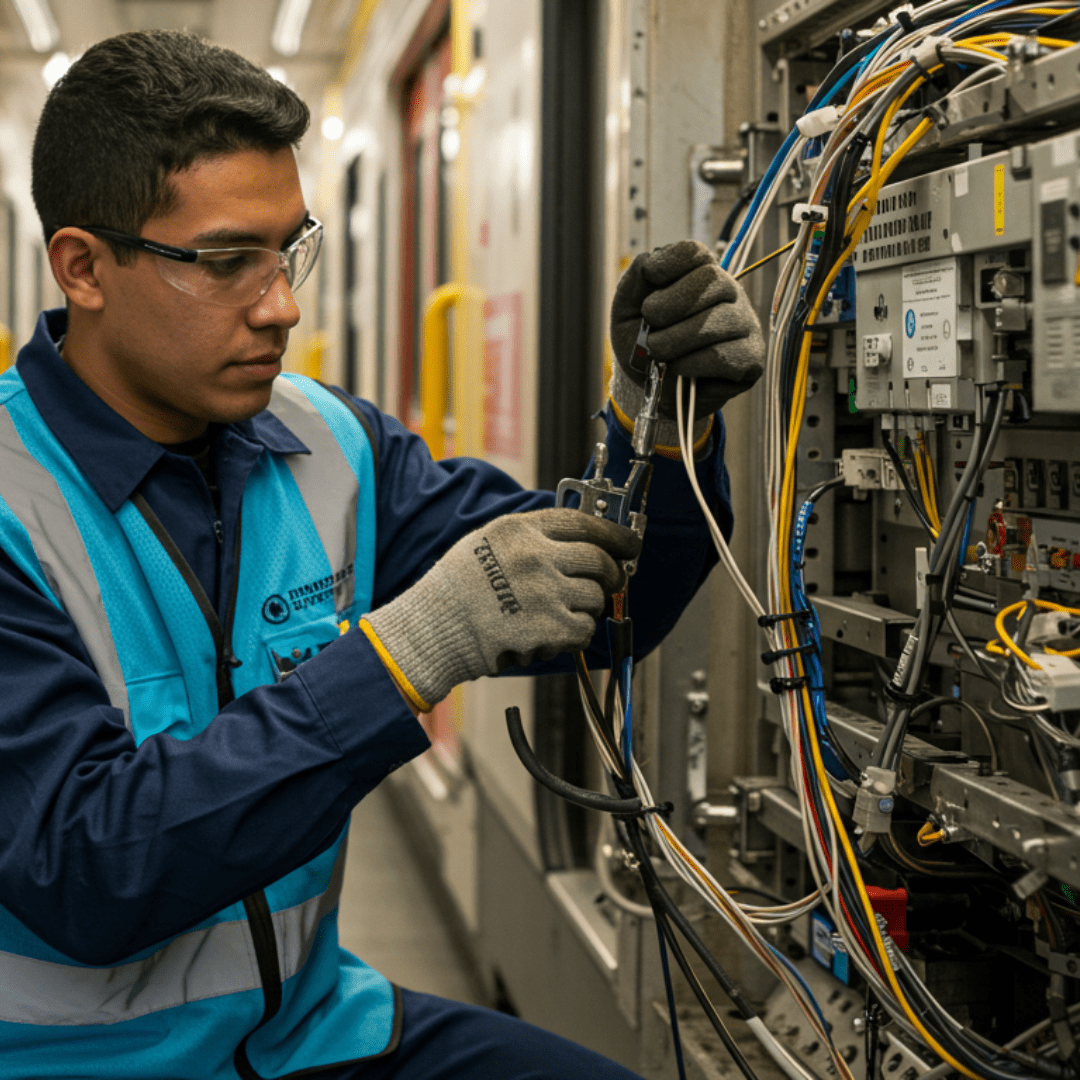

High-voltage cable assemblies route power safely and reliably in applications where system voltages exceed standard low-voltage ranges. They’re used in industrial equipment, medical devices, test rigs, EV infrastructure, renewable energy systems, rail traction, and power distribution modules.

OurPCB designs and manufactures custom high voltage cable assemblies built to IPC-A-620 workmanship standards, with materials and layouts selected specifically for voltages around 1 kV+. Each assembly is tested electrically and mechanically to help ensure long-term reliability and safety in demanding applications where failures can mean equipment damage, downtime, or safety hazards.

What are High Voltage Cable Assemblies?

High voltage cable assemblies are engineered combinations of conductors, insulation systems, connectors, and protective coverings designed to transmit power at elevated voltages with controlled electric fields and robust mechanical support.

Modern high voltage cable assemblies can incorporate single-core, multicore, or coaxial constructions, as well as shielding and grounding strategies to control partial discharge and electromagnetic interference while maintaining safe and stable operation.

What are the Benefits of High Voltage Cable Assemblies?

The benefits of high voltage cable assemblies include their safety over generic wiring. By tailoring insulation, creepage, and clearance distances to each design, manufacturers can provide pre-terminated, pre-tested assemblies with clear labeling and keyed connectors, which cut installation time and reduce wiring errors compared to standard wiring. They also integrate power, control, and sensing lines with engineered shielding and grounding for advanced, modular, low-noise high-voltage systems.

- Materials selected for temperature, humidity, and environmental exposure

- Strain relief and mechanical supports reduce fatigue at connectors and transitions

- Robust jacketing and protection reduce abrasion and damage in dynamic applications

- Pre-terminated, pre-tested assemblies simplify installation in equipment and systems

- Clear labeling and keyed connectors reduce wiring mistakes at the final build stage

- Standardized cable sets across product lines simplify production and service

- Integrates power, control, and sensing conductors where appropriate

- Shielding and grounding layouts designed to limit noise in sensitive electronics

- Configurable for modular power systems, test fixtures, and plug-in HV modules

Superior Field Reliability

- IP67-rated connectors resist complete dust ingress and withstand water immersion up to 1 m for 30 minutes.

- Marine-grade insulation materials provide chemical resistance against fertilizers, pesticides, and fuel exposure.

Extended Equipment Lifespan

- Temperature-resistant components function reliably from -40 °C to 105 °C, preventing heat damage in engine compartments.

- Reinforced strain relief and secure terminal connections prevent failures from constant diesel engine vibration.

Simplified Troubleshooting

- Color-coded wiring with clear detail reduces diagnostic time by up to 60%.

- Comprehensive documentation includes wiring diagram specifications specific to your tractor model.

Customization Options

- Exact-fit design ensures perfect compatibility with your specific Farmall or Cub Cadet restoration.

- Additional capacity options accommodate future implements or aftermarket electrical accessories you may add later.

Why Choose OurPCB for High Voltage Cable Assemblies

- IPC-A-620 based assembly processes with specific HV handling procedures

- Defined inspection points for insulation integrity, terminations, and routing

- Electrical tests aligned to your specified working and test voltages

- Assemblies tailored to your voltage class, geometry, and environmental constraints

- Support for unique connector systems, bushings, feedthroughs, and terminations

- Flexible engineering collaboration from prototype through production

- Rapid prototypes and pilot builds for validation and certification testing

- Scalable manufacturing for recurring orders and multi-unit systems

- Planning and scheduling aligned with product development and rollout timelines

- Ability to combine high voltage cable assemblies with low-voltage harnesses and PCBs

- Pre-integrated subassemblies that simplify your internal wiring and assembly steps

- Single-source coordination for multiple electrical components and harness types

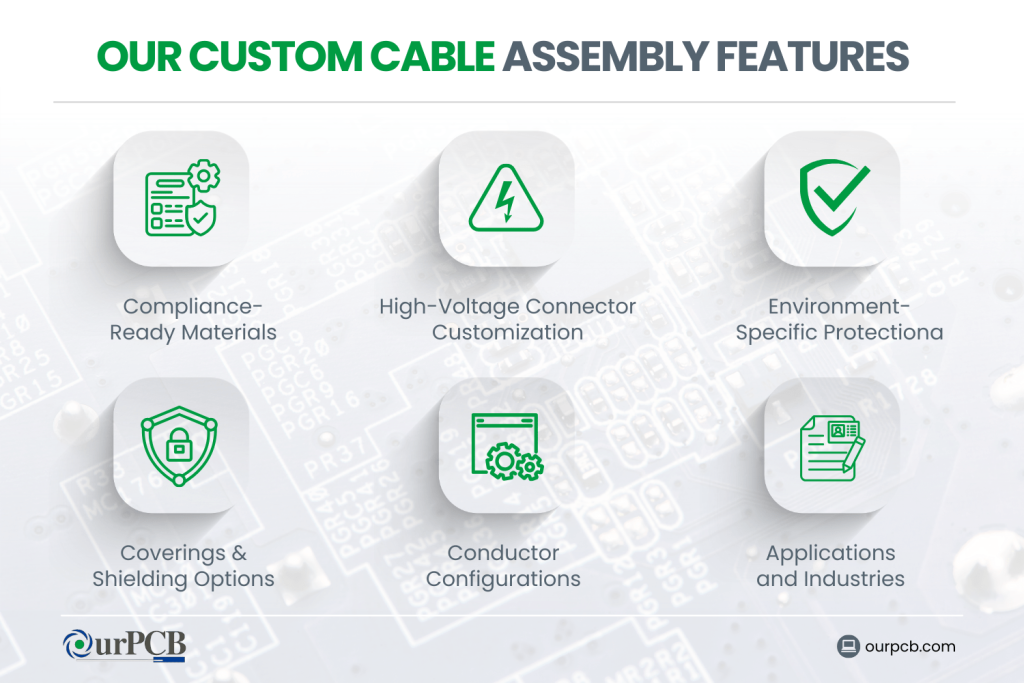

Our Custom Cable Assembly Features

Compliance-Ready Materials

- Cables with insulation systems rated for your required voltage and temperature range

- Options for low-smoke, halogen-free, and other specialized compounds based on standards or project requirements

- Material selection guided by environmental factors such as humidity, altitude, and contamination levels

High-Voltage Connector Customization

- Support for industry-recognized high-voltage connector families where specified

- Custom overmolded or potted terminations to improve insulation and strain relief

- Interfaces for bulkhead feedthroughs, panel connectors, and equipment-side terminations

Environment-Specific Protection

- Additional jackets, tubing, and boots to protect against abrasion and contamination

- Solutions for indoor, outdoor, and cabinet-mounted applications

- Localized reinforcement at bend points, cable entries, and motion interfaces

Coverings & Shielding Options

- Heat shrink tubing, molded boots, and over-braid for mechanical and electrical protection

- Metallic or foil shields tied into defined grounding schemes

- Segregation of HV, LV, and signal conductors within an integrated harness, when required

Conductor Configurations

- Single-core, multi-core, or coaxial designs according to load and layout

- Conductor sizes selected to manage current, voltage drop, and thermal performance

- Custom lengths, breakouts, and routing geometry to match your equipment design

Applications and Industries

- Industrial power equipment and drives

- Medical and laboratory high-voltage devices

- EV and battery testing infrastructure

- Renewable energy and power conversion systems

- Test stands, burn-in rigs, and certification equipment

Millions of business and innovators use OurPCB

Our Custom Wiring Harness Process

Fast, free, and includes a production timeline

Our engineers create your design schematic and select the right materials

We’ll manufacture a high-quality prototype within 7 days

The prototype goes through various functionality and stress tests

Cutting, stripping, and assembly to the highest standard

After final testing and packaging, your custom wiring harnesses are delivered

Technical Capabilities

OurPCB runs controlled production for high-voltage cable assemblies, from early prototypes through repeatable builds for 12 to 800 V systems. Automated cutting and stripping handle 40 AWG to 120 mm² copper conductors for power, control, and auxiliary circuits. Solid or stranded conductors use insulation systems chosen for voltage, creepage, and temperatures from −40 °C to 150 °C.

Shielded, coaxial, and custom cable constructions support EMI control, grounding, and safe clearances in demanding high-voltage equipment. Precision crimping with crimp-force monitoring, soldering, overmolding, potting, and encapsulation protect terminations and manage electric fields at stress points. Each high-voltage assembly can be tested for 100% continuity plus insulation resistance above 100 MΩ at 500 VDC.

Capabilities & Services

- Wire Gauge: 40AWG-120mm²

- Production Capacity: 10,000 pieces/hour

- Wire Cutting Service

- Wire Stripping Service

- Wire Marking Service

- Label Types

- Wire Ends Treatment

Custom Wire/Cable Service:

- Wire/Cable types

- Wire gauge

- Wire/Cable length

- Insulation/Jacket color

- Core numbers etc.

Custom Cable Assembly Capacities:

All kinds of cable assemblies including

- Electrical cable assembly

- Coaxial cable assembly

- Multi-core cable assembly

- Connector to board cable assembly

- Automobile communication cable assembly

- Power transmission cable assembly

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

High Voltage Cable Assembly FAQs

What voltage ranges can your high voltage cable assemblies support?

We design assemblies around your specified operating and test voltages—typically starting at ~1 kV and extending into higher-voltage ranges, with cable types, insulation thickness, shielding, and creepage/clearance chosen to match your application and governing standards.

To quote a high-voltage cable assembly, we typically need your cable specs and voltage ratings, connector types (with drawings/datasheets), any assembly or routing drawings (or photos/samples), required electrical tests (e.g., hipot level, insulation resistance), and your expected quantities and lead times.

How do you ensure safety and quality in high voltage assemblies?

We ensure safety by using cables, connectors, and insulation systems explicitly rated for the required working and test voltages, with appropriate safety margins and compliance to relevant IEC/UL requirements. Each assembly then undergoes electrical testing and staged visual/mechanical inspections throughout production to verify insulation integrity and build quality.

What lead times should I expect for custom high voltage cable assemblies?

Lead times for custom high-voltage cable assemblies depend on design complexity, quantities, and material availability, but as a guide, simple assemblies can be completed in a few days while more complex builds may take several weeks. For most cable projects, we typically work to a standard lead time of around 10–15 days with expedited options available for prototypes or urgent requirements, while higher-volume and recurring orders are planned against forecasts and blanket schedules to keep deliveries predictable.