Wires are arguably the most typical items in electrical equipment (wire harnesses and cable assemblies) and devices. But these wires are not the same. Upon close inspection, you will find that some have a single solid core while others have several thin wires. These are solid and stranded types of wires. In this article, we will compare stranded vs. solid wire to learn more about the properties of the two. Take a look!

Contents

- What Are Stranded Wires?

- How To Make Stranded Wire

- Stranded Wire Construction Types

- Stranded Wire Applications

- Stranded Wire Pros

- What Are Solid Wires?

- How To Make Solid Wire

- Solid Wire Applications

- Solid Wire Pros

- Solid Wire Cons

- Stranded vs. Solid Wire: The Differences

- Stranded vs. Solid Wire: Current Capacity

- Stranded vs. Solid Wire Resistance

- Routing

- Flexibility

- Cost

- Stranded vs. Solid Wire: Manufacturing Complexity

- Strength

- Distance

- Stranded vs. Solid Wire: Superiority

- Stranded vs. Solid Wire: Are Stranded or Solid Wires Better Power Cables?

- Stranded vs. Solid Wire: Can I Use Stranded Wire Instead of Solid Wire?

- Conclusion

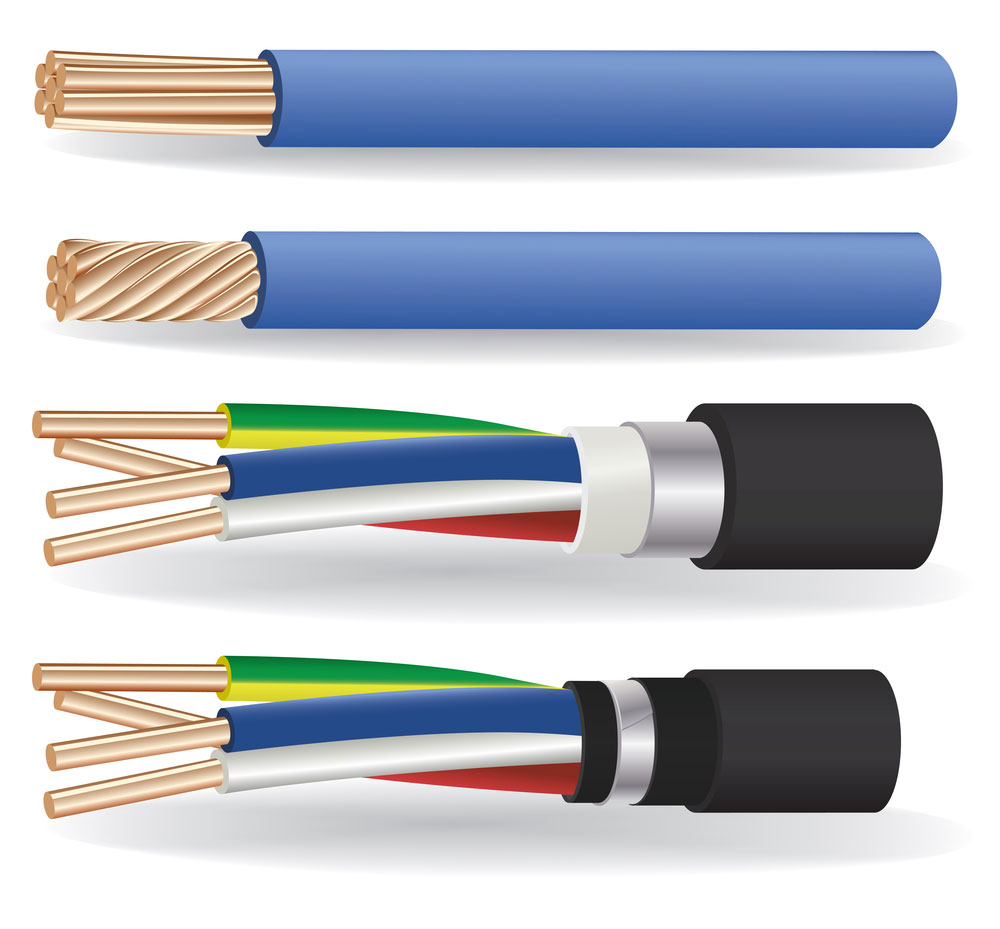

What Are Stranded Wires?

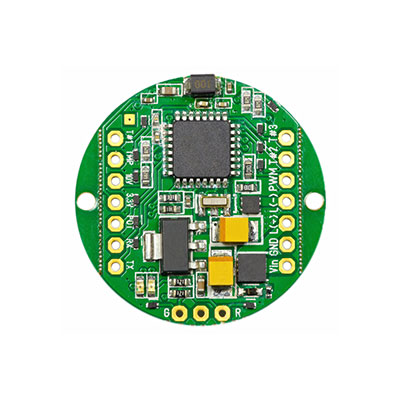

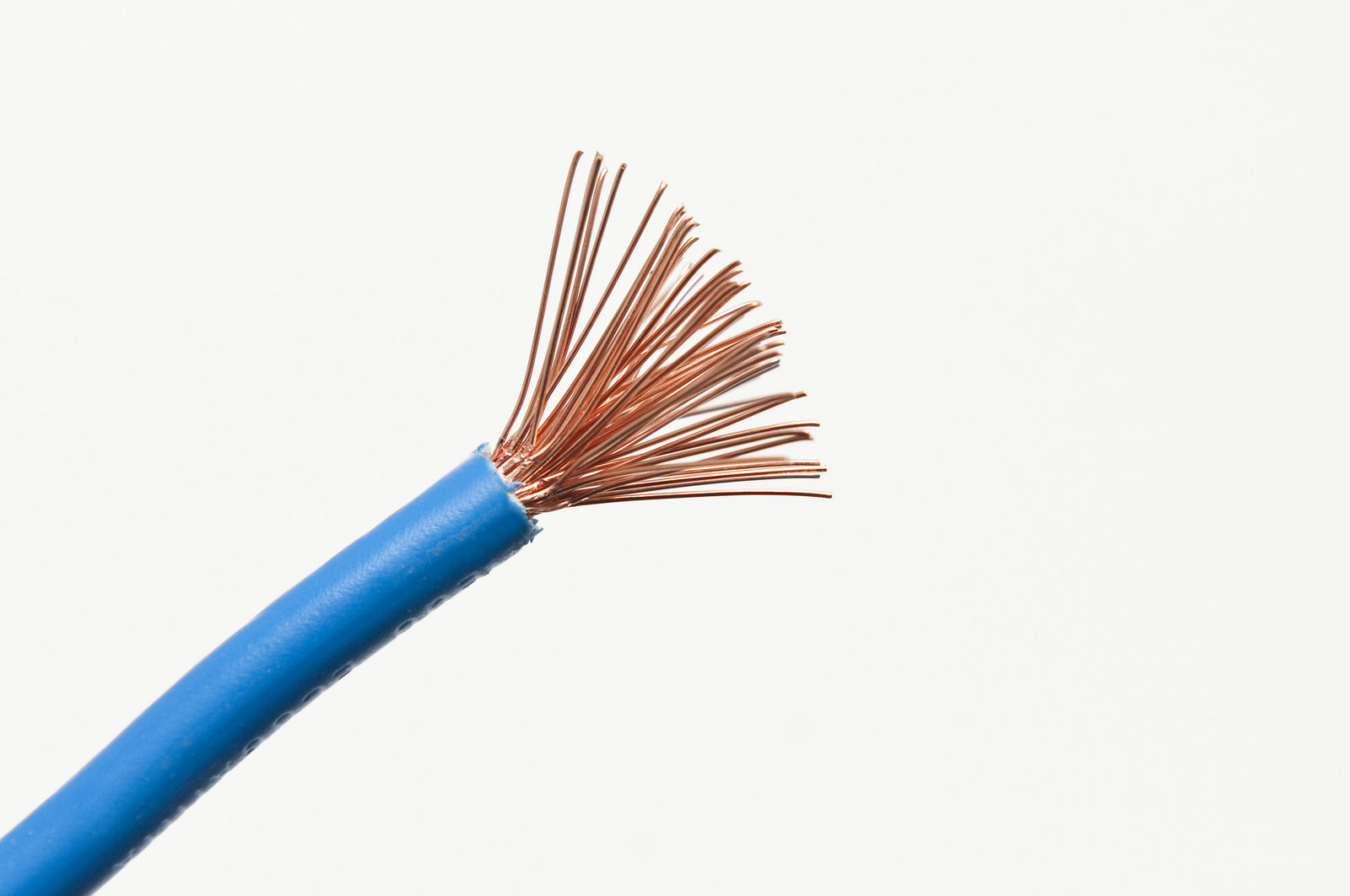

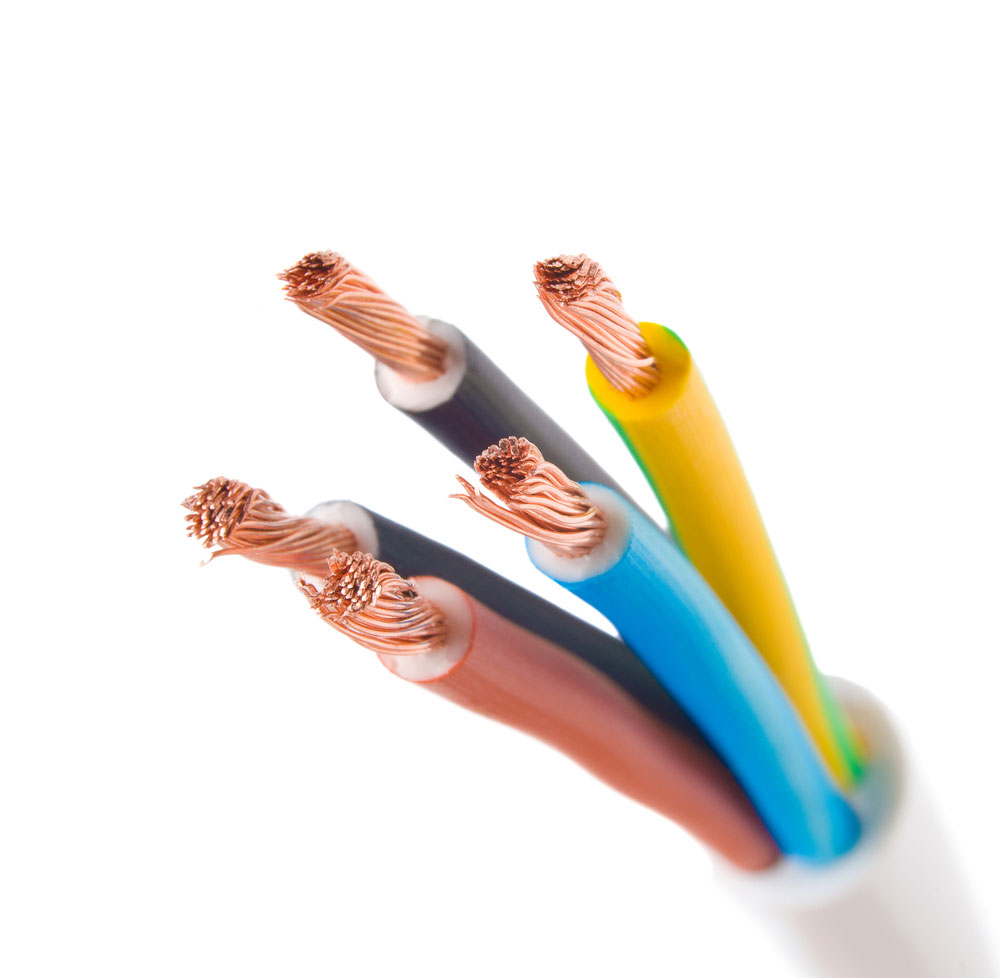

Stranded wires are cables consisting of multiple tiny gauge wires compressed, twisted, and insulated together to create organized bundles.

A stranded electrical power cable

How To Make Stranded Wire

Making stranded wire involves drawing and annealing individual strands first. After that, a machine twists several strands around a center wire. These individual wire strands can be 30 or 34 AWG (American Wire Gauge) in size. The stranded wire can have seven or more of these thin pieces. And the flexibility of the resulting stranded wire increases as the number of wire strands increases.

Stranded Wire Construction Types

Stranded wire twisting falls into the following four categories.

Bunch Stranding

This stranding technique twists the strands of wire in one direction without considering their arrangement geometrically.

Concentric Standing

Concentric stranding lays at least one helix-laid wire layer around a solid core wire. Each of these layers contains six or more single strands of wire than the previous one. Additionally, each layer runs opposite to the direction of the preceding layer unless it is the compact version of concentric stranding.

copper wires

Unilay Stranding

This stranding resembles the concentric type but with two differences. The lay direction and length are the same in the layers.

Rope Lay Stranding

This stranding is similar to concentric stranding but with the component strands individually stranded. Also, the group count forming the rope and the strand count in every group define the rope-lay type of stranded conductor.

Stranded Wire Applications

Stranded wires have the flexibility advantage compared to solid wires of a similar size. And this factor determines the cable's applications. The wires are ideal for situations requiring frequent movement, flexing, or vibrations, such as on a robot arm.

Stranded copper wires

The cables are also suitable for routing through confined spaces where you need intricacy. These include in-patch cabling, headphone cables, and appliance cables. For complex projects requiring organized routing of multiple stranded or solid wires across industrial, telecommunications, or electronics applications, working with a custom wiring harness manufacturer can provide pre-assembled solutions tailored to specific environmental and performance requirements.

Stranded Wire Pros

- Flexible

- Will not split/sever

- Malleable

- Stranded Wire Cons

- Increased chances of corrosion in outdoor applications than solid wire due to the extra surface area

- Has a higher voltage drop

- Lower current carrying capacity than solid wires due to the air gaps

- More expensive because they are complex to manufacture

- Noisy sound with 20-50% attenuation

- Medium transmission performance when handling high-frequency signal transmission

- More difficult to terminate because the strands can break when peeling the insulation or fitting them into the terminal

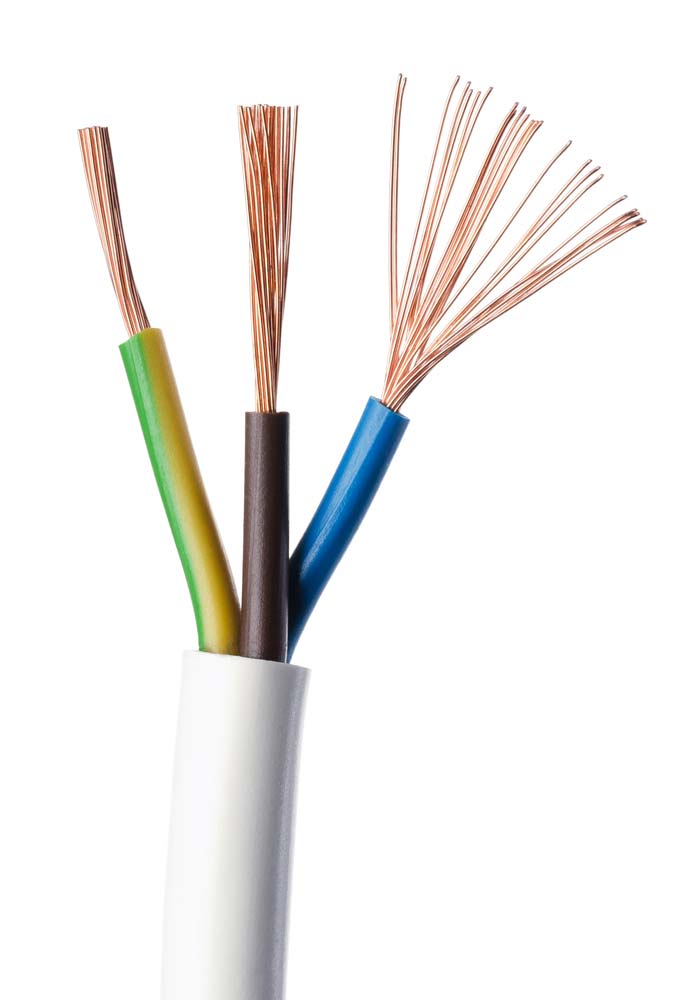

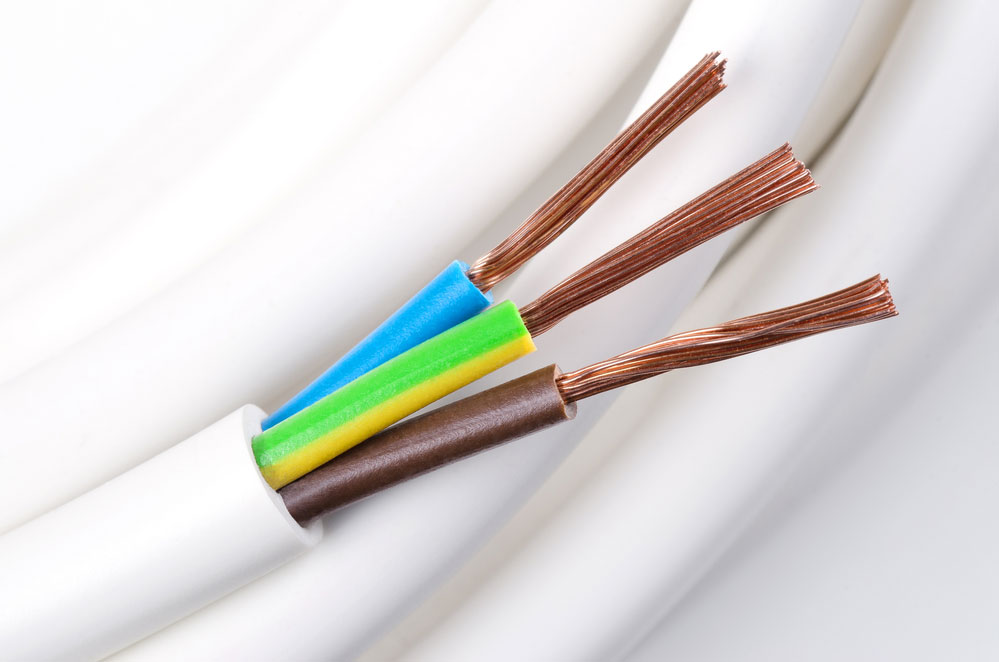

An IEC standard electrical power cable with three-stranded wires (live, earth, and neutral)

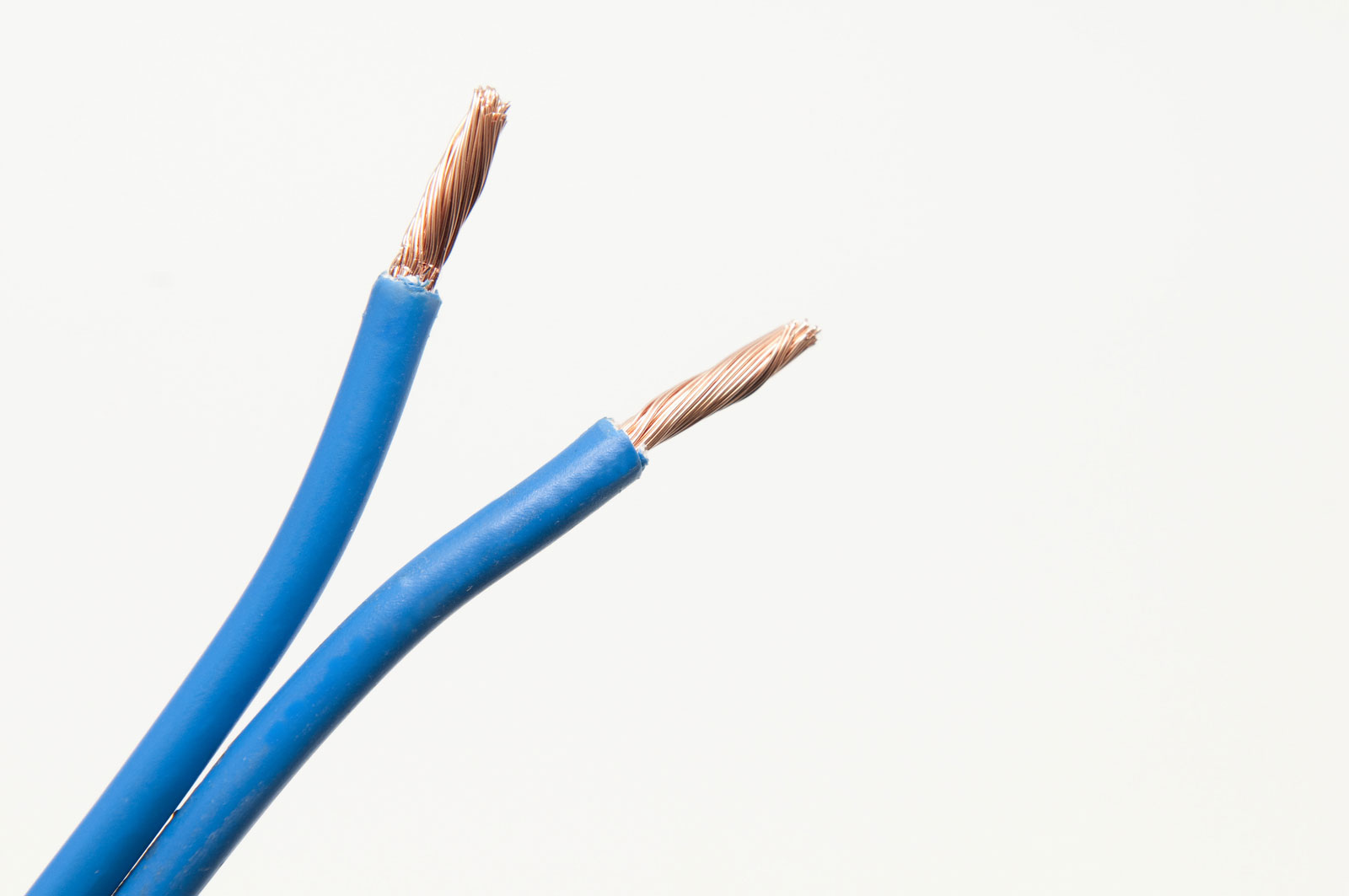

What Are Solid Wires?

Solid wires are electric cables consisting of single solid conductive cores. The solid conductor is heavier and thicker than its stranded wire counterpart. Also, it is resistant to extreme environmental conditions, weather, and frequent movement.

Two solid wires

How To Make Solid Wire

The process involves drawing copper rods using a set of small dies that gradually become smaller until you get the required wire gauge. These rods become thinner and more brittle the more they get stretched.

So they undergo an annealing process (heating) to make the copper wire ductile and sturdier. After annealing is insulation, then the wire is ready to use.

Solid Wire Applications

This rugged, low-cost wire has the durability advantage because it is anti-corrosive. Therefore, it is ideal for outdoor applications. Additionally, it has a high current capacity and can withstand frequent movement.

Besides that, the wire is suitable for the following applications.

- Backbone Cabling: Comprises transmission media, cross-connects, main & intermediate terminations, CAT6 cables, and straight pinned backbone wires on wall jacks and patch panels.

Solid copper wires in twisted pair

- Inter and Intra-Building Connections & Vehicle Controls: Solid wires are ideal for cabling in vehicles, buildings (equipment rooms, telecommunication closets, etc.), home electrical wiring, and from one building to another.

- Protoboard Wiring (Breadboard wiring): Solid cables are easier to force into breadboards and PCB holes. Stranded wires will unravel if you try to push them into these holes.

Solid Wire Pros

- Low cost

- Anti-corrosive

- Weather resistant

Solid Wire Cons

- Less flexible and can break when bent several times

- High skin effect when handling high voltage transmissions

- Unsuitable for electronics, computer, or digital applications

Special Offer: Get $100 off your order!

Email [email protected] to get started!

Stranded vs. Solid Wire: The Differences

These signal/power cables have unique advantages that make them suitable for different applications. Here's a head-to-head comparison that shows how each wire fairs.

Solid vs. stranded wire

Stranded vs. Solid Wire: Current Capacity

Electricity causes a skin effect when it goes through wires. The parts closer to the exterior layer are more exposed to electromagnetic fields, resulting in electricity losses in the air.

A solid wire is thicker than the stranded type, so its surface area for current dissipation is smaller. The thinner wires in stranded cables contain air spaces and a larger surface area that increases dissipation. Therefore, these cables have a lower current carrying capacity.

On top of that, thinner strands (with a high gauge of wire) have higher insertion losses than thicker wires. Therefore, stranded wires experience between 20% and 50% more attenuation than similar gauge solid cables. The DC resistance is also higher because the stranded cable's surface area is not all solid copper.

Stranded vs. Solid Wire Resistance

Two factors affect a wire’s resistance: its cross section/diameter and length. Let’s begin with the stranded wire’s structure. The individual copper strands don’t run straight from one end to the other. Instead, they run in a spiral pattern, which makes the conduction path longer than what you see on the skin.

This longer design increases the wire’s resistance compared to the straight solid wire.

When considering the diameter, stranded wires have air gaps between the strands, meaning that a 6-gauge stranded wire has a smaller conduction cross-section than a 6-gauge solid wire.

This reduced conduction surface also increases a stranded wire’s resistance.

However, these phenomena only apply to DC power transmission. When transmitting AC at high frequencies, the skin effect places the odds in favor of stranded wires because the current tends to crowd at the surface of the conduction path.

AC high-voltage power transmission lines

Since stranded wires have more surface area than their solid wires, they provide more real estate for current transmission to the other end.

Therefore, the resistance between the two wires also depends on the type of power you’re transmitting.

Routing

Stranded wires are more flexible, making them more bendable and ideal for routing. Therefore, it is easier to maneuver them around objects than their solid counterparts.

Stranded wires packaged together.

.

Flexibility

Solid wire cables are stronger and more rigid, but flexibility is not their forte. So applications requiring frequent flexing and vibrating are better for stranded wires.

Cost

Solid copper conductors are cheaper to manufacture because the process requires a few steps and is faster. Manufacturers only need to draw, anneal, then insulate the cable.

Making stranded cables follows the same process, but there is the additional step of twisting the individual strands to create the final product. This extra process increases manufacturing costs.

Stranded vs. Solid Wire: Manufacturing Complexity

Manufacturing a single wire is not only cheaper, but it is easier. So making solid wires is simpler than manufacturing multiple tiny high-gauge copper wires, then twisting them together.

Strength

Solid copper is sturdier and more rugged than several thin cables put together. Additionally, the wire is thicker, heavier, and weather-resistant. Stranded wires have air gaps that increase the surface area for corrosion when exposed to the elements.

Stranded copper wire. Note the air spaces between the strands.

Distance

Solid wire cables dissipate less current. So they can transmit more power along lengthy lines. These wires are also better for signal lines because they have lower attenuation.

And there is another factor to consider. Wiring requires electricians to pull cables through long conduits in buildings. Solid wires can withstand the tension without snapping.

Stranded vs. Solid Wire: Superiority

No wire is better than the other when you compare the two. Each has unique advantages that make it suitable for specific applications. Once you determine the ideal wire for the job, the next crucial factor is to pick the precise wire gauge.

Stranded vs. Solid Wire: Are Stranded or Solid Wires Better Power Cables?

Several factors come into play here.

When transmitting DC power, such as from solar panels to batteries and from batteries to the inverter for conversion to AC, solid core wires are better because they have a lower resistance for the same gauge and length.

But when handling AC in a building’s wiring system or the grid, stranded cables are more efficient. Stranded wires are more flexible than their solid core counterparts, meaning they will last longer when you have to bend them every time (non-fixed installation).

For instance, electrical appliances and phone charges must have stranded wires to withstand constant movement and flexing during use.

An iPhone charge (note the coiled cable)

And on durability, solid core wires have a smaller surface area for corrosion. So, they will last longer if installed in an area exposed to the elements, and they don’t have outer insulation.

In a nutshell, you have to look at the advantages and disadvantages of each wire to that specific application.

For instance, while solid wires have a lower surface area for corrosion in outdoor applications, the skin effect is weightier when considering AC transmission. This explains why AC power lines are stranded wires.

Stranded vs. Solid Wire: Can I Use Stranded Wire Instead of Solid Wire?

You can replace solid wire with stranded wire, especially if the skin effect has a significant impact on current transmission.

However, the replacement stranded cable should have similar or higher electrical ratings (amperes and voltages) than the solid type. If these values are lower ratings, the wire will get hot because of the increased resistance.

Conclusion

There you have it! Solid and stranded wires have one physical difference that creates more variations in several other factors. These variations give each wire type specific applications, as you have seen above. That's it for now, and if you have any questions or have something to add, reach out and drop a comment.

Special Offer: Get $100 off your order!

Email [email protected] to get started!