Fabricating and assembling circuit boards can be a complex and expensive affair. As a new customer in the PCB industry, you might get confused with how PCB manufacturing companies price different products. So, it is vital to do PCB cost estimation to help you plan and budget for your electronics project. We will look at these cost estimation factors and ways to approximate board costs accurately. Let's get started!

Contents

- How Much Does PCB Assembly Cost?

- PCB Cost Estimation Factor

- A. Pre-Production Inspection and Review

- B. PCB Design

- C. PCB Manufacturing Cost Drivers

- 1. Lead Time

- 2. Number of Boards

- 3. Board Size, Materials, Layers, and Number of Sides

- 4. Surface Finish/Plating

- 5. Number and Size of Via Hole

- 6. Filling Vias

- 7. Mechanical Holes

- 8. Conductor Size and Spacing

- 9. Add Ons

- D. PCB Assembly Process Cost Drivers

- 1. Number and Type of Components

- 2. Single vs. Double-Sided Assembly

- 3. SMD Components Lead Pitch

- 4. BGAs

- 5. IPC Class (Inspection Charges)

- 6. ITAR Compliance

- 7. Inspection, Testing, and Qualification

- How To Estimate Circuit Board's Manufacturing and Assembling Costs

- PCB Cost Calculator

- Consult a Reputable PCB Manufacturer

- Determining PCB Cost Per Square Inch

- How to Reduce PCB Cost on Printed Circuit Board

- Wrap Up

How Much Does PCB Assembly Cost?

The PCB assembly cost for 50 units, each with 100 square inches, will range from $100.00 to $250.00, based on an assembly rate of $0.02 to $0.05 per square inch.

| PCB Specifications | Quantity | Cost per PCB (USD) | Total Cost (USD) |

| PCB Manufacturing (Size: 10x10cm, FR4 Material, 2 Layers) | 50 | $1 to $5 | $50.00 to $250.00 |

| PCB Assembly (Square Inch Assembly Cost) | 50 | $0.02/inch² (100 inch²/PCB) to $0.05/inch² (100 inch²/PCB) |

$100.00 to $250.00 |

However, this is a general estimate, and the actual cost can vary significantly based on several key factors:

- Required Assembly Labor: The amount and complexity of labor involved in assembling the PCB.

- Prevailing Labor Rates: The current labor rates in the region where the assembly is being performed.

- Assembly Time: The time required to complete the assembly process, influenced by factors such as the number of components and the complexity of the layout.

- Overhead Manufacturing Expenses: The costs associated with running the manufacturing facility, including utilities, equipment maintenance, and administrative expenses.

- Design Complexity of the Board: More complex designs with densely packed components or advanced features may increase the assembly cost due to the need for more precise work and specialized equipment.

These factors combine to determine the final cost of PCB assembly, making it important to consider each one when estimating your project’s expenses.

PCB Cost Estimation Factor

A. Pre-Production Inspection and Review

Each PCB fab house offers varying service levels in pre-production inspection, engineering & design review, and DFM review. These levels attract different costs, with the most thorough inspection and review process being the most expensive.

But PCB designs must undergo some basic inspection and review before you get a quote to ensure it is manufacturable. So your project might receive a "no-bid" marking until you rectify errors like clearances.

An engineer checking a PCB design using CAD software

It is vital to note that a design might not trigger a DFM violation when considering the fabrication ability. However, it might create an assembly defect or product failure, for instance, if pads are too close to each other with insufficient solder mask definition.

An affordable basic-level inspection might fail to identify this issue, but expensive advanced-level checking will flag the issue.

B. PCB Design

We will not include the design time cost because this is your task as a board designer. So if you are not a PCB designer, this design time will be an additional cost. And the longer it takes, the higher the price.

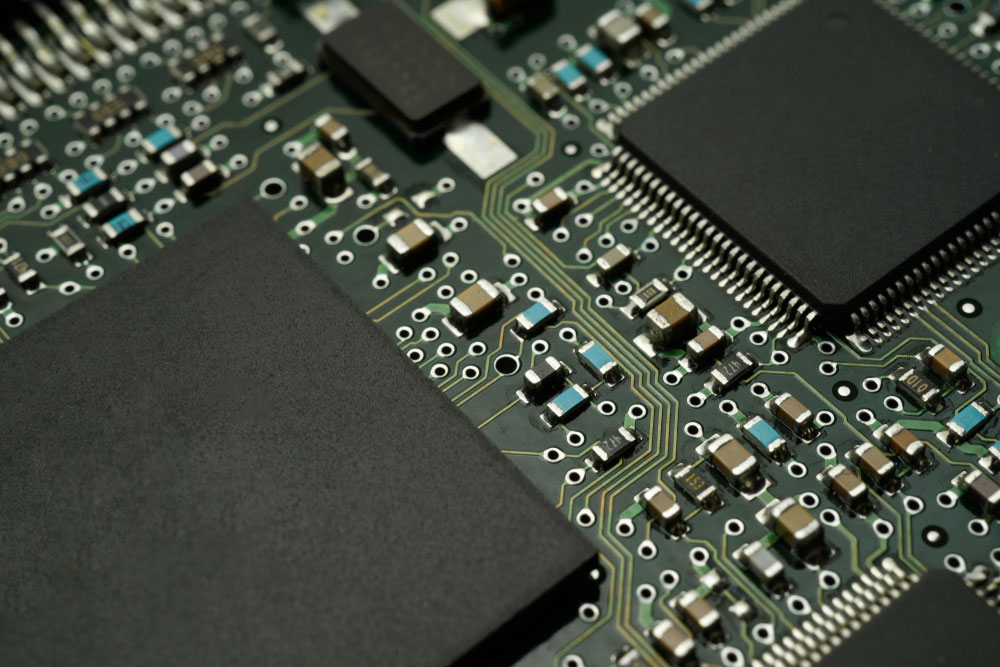

A circuit board design

Keep in mind complex boards take longer to design and require thorough pre-production inspection & review, which will push the circuit board cost higher. However, the cost might be negligible with a high board quantity.

Special Offer: Get $100 off your order!

Email [email protected] to get started!

C. PCB Manufacturing Cost Drivers

The crucial factors that drive the manufacturing costs once the design goes into the fabrication phase include the following.

1. Lead Time

Shorter lead times lead to higher costs because the fab house will have to take extra measures to ensure the project's success. For instance, they might have to source your board materials immediately, halt other production processes to focus on yours, allocate extra man and machine power to your project, etc.

But longer lead times are more forgiving to the pocket because they give fab houses the ability to allocate resources more efficiently. So be prepared to pay more if you want quick-turn PCBs.

2. Number of Boards

Although manufacturing more boards raises the total project cost, it reduces the price per board. Panelization helps reduce the cost by manufacturing several boards per panel as a single array, which goes through the assembly line efficiently.

3. Board Size, Materials, Layers, and Number of Sides

Large boards require more dielectric and conducting materials, plus more components. And they might need different materials, such as copper foil, polyimide, or fiberglass. FR4 is the most typical and cheapest material, but polyimide and Rogers are expensive.

Alternatively, you can design multilayer and double-sided boards to create compact circuits, but manufacturers will still require more materials to build the additional layers, leading to a higher cost. Also, double-sided boards are more complex and expensive to make but enable you to make compact circuits with multiple components.

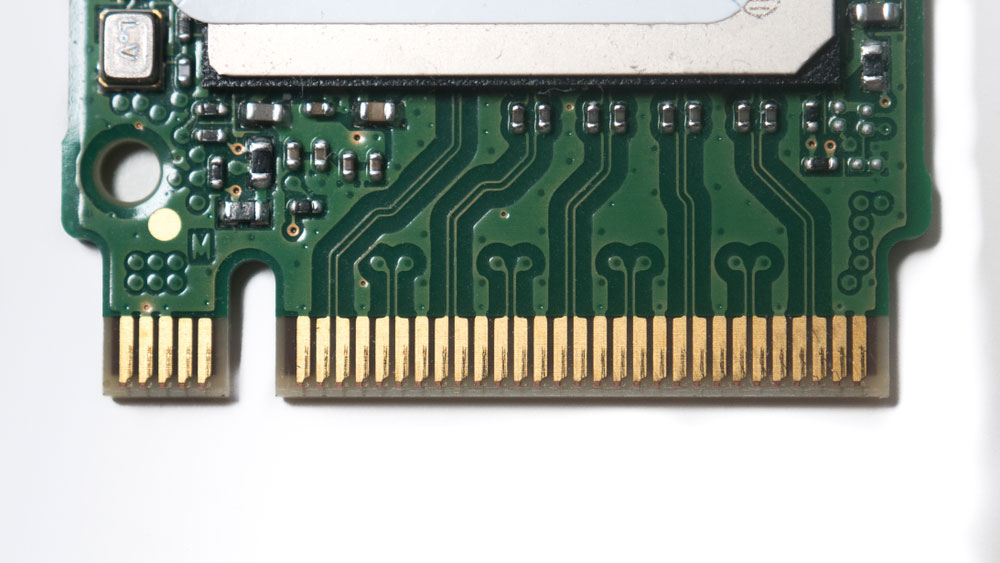

4. Surface Finish/Plating

HASL and tin-lead are some of the cheapest plating processes but do not provide the best corrosion resistance. Gold and silver finishes give the best surface protection but can increase the cost per board by up to 10%.

5. Number and Size of Via Hole

Tiny via holes less than 0.012 mils need advanced laser drilling techniques that might require an adjustment in the manufacturing processes. These holes can increase project costs by 10%-20%. And the more the number of holes, the higher the price increase.

6. Filling Vias

Manufacturers don't fill vias to the top, but some projects require complete filling. Such cases require specialized conductive or non-conductive materials that can add at least an extra 10% to the project's cost.

7. Mechanical Holes

Cost varies depending on the hole shape, size, and plating.

8. Conductor Size and Spacing

Like vias, smaller conductor sizes and spacings are more complex to achieve. So they increase the overall project cost.

9. Add Ons

Some boards require special features due to their application areas. These include complex routing, countersinks, controlled depth drilling, and counter bores. These extra features require additional manufacturing processes and cutting-edge tooling that adds 5-10% to the overall fabrication cost.

D. PCB Assembly Process Cost Drivers

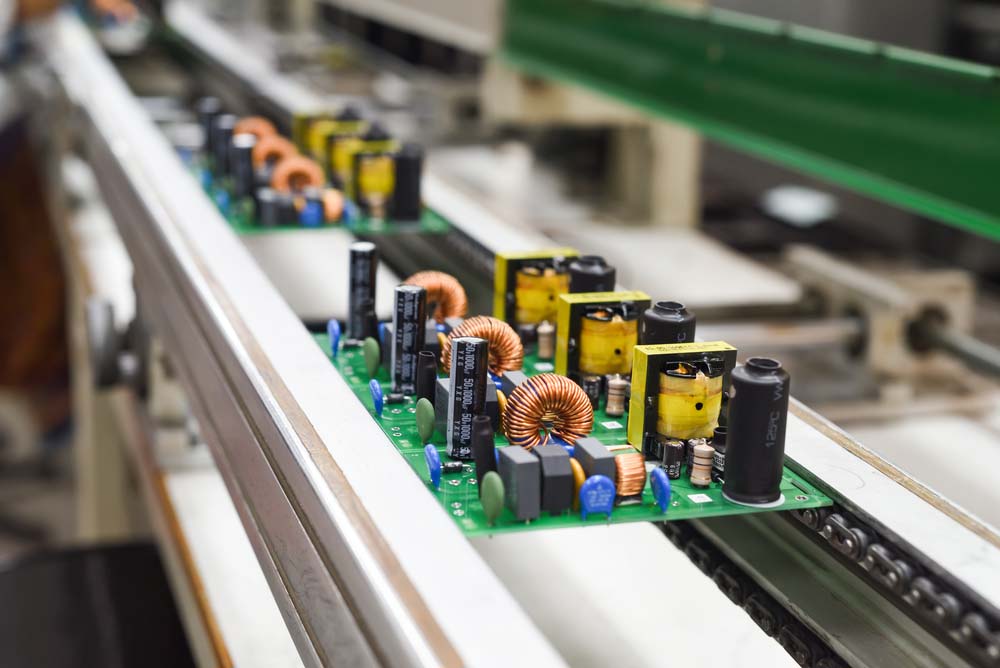

If you want the bare boards, there will be zero assembly expenses. But these cost drivers will affect the product price if you require assembled boards.

1. Number and Type of Components

Ordering components in bulk reduces the cost per piece. But if your boards need unique parts, the price will be high. On top of that, an all-SMD assembly can increase the cost by 50% more compared to a through-hole setup.

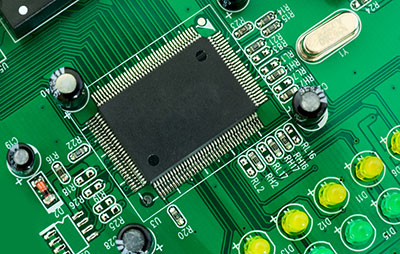

Electronics factory workers assembling PCBs

2. Single vs. Double-Sided Assembly

Not only do they require more components, but double-sided boards also have higher assembly costs because the PCBs have to go through the assembly line twice. Plus, they incur higher NRE costs through the process.

3. SMD Components Lead Pitch

Most manufacturers don't increase the cost due to SMD lead pitch if your board has an all-SMD assembly. But you'll pay extra if it has a mix of SMD and thru-hole components.

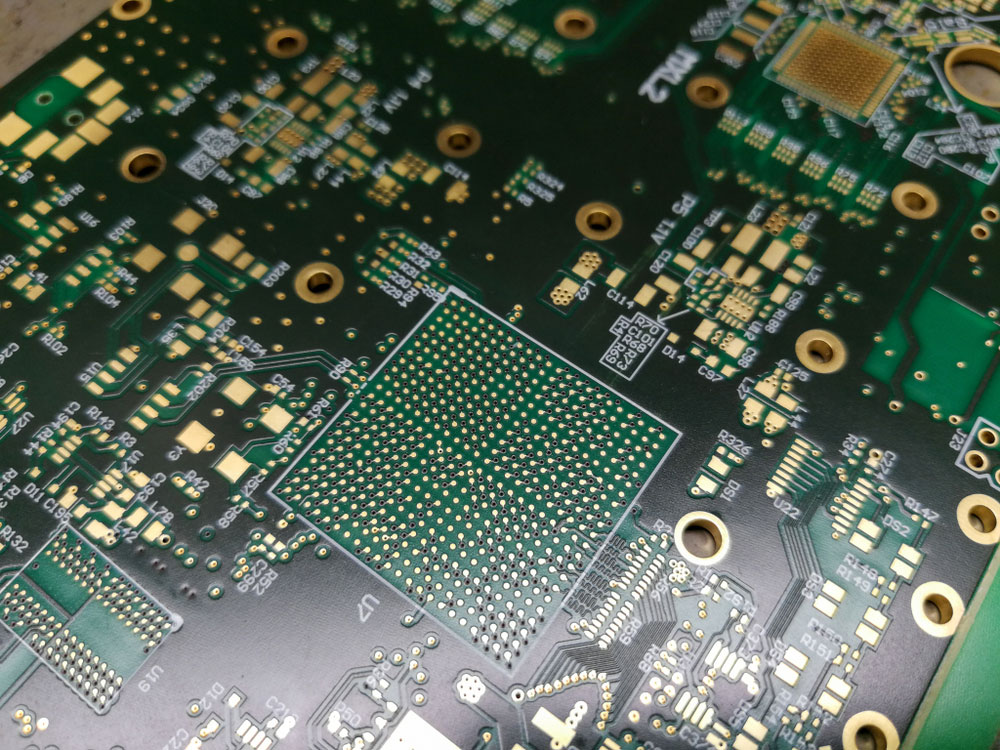

4. BGAs

Single/double-sided BGA components can increase the cost by 20% compared to other SMT assemblies.

A ball grid array on a PCB

5. IPC Class (Inspection Charges)

Production and assembly to match IPC-A-600 class 3 standards will be costlier due to the extra inspections required to ensure the processes comply with the required specifications.

6. ITAR Compliance

ITAR compliance increases assembly costs due to the strict PCB integrity, data integrity, and shipping requirements.

7. Inspection, Testing, and Qualification

These activities are necessary after assembly to ensure the board does not have defects. The cost depends on the level of inspection & testing and the required qualification standards.

How To Estimate Circuit Board's Manufacturing and Assembling Costs

Considering the factors above, there are two ways to get the estimated cost of building your PCB.

PCB Cost Calculator

Most PCB manufacturers embed PCB cost calculators in their websites to enable potential customers to calculate and estimate the production of a circuit board. But since the fabrication and assembly processes are complex, combining all the factors into one program is challenging.

So you might get a PCB assembly cost calculator, a flex PCB cost calculator, and a PCB design cost calculator as different programs.

Consult a Reputable PCB Manufacturer

Although calculators are quick and enable you to do the math considering all factors, they might not be as accurate. So it is better to contact a reputable PCB manufacturer to get a more precise cost breakdown. At OurPCB, we provide free quotes for PCB designs to help reduce costs for our customers. And we have the required expertise, equipment, and experience to build high-quality circuit boards for your project.

Determining PCB Cost Per Square Inch

To obtain a rough cost for your PCB, you must consider several factors. First, most manufacturers charge per square inch of the board. Therefore, your PCB design will immensely matter in the cost determination.

What also dictates this cost is the total number of PCBS you want. Unlike typical manufacturing, where a small number will translate to a lower cost, this is different. Here, ordering a few PCBs may result in a higher per-inch cost.

In addition, have a well-thought-out bill of materials. The manufacturer will demand you furnish them with this document. Basically, what they want to know is your desired PCB quality or materials you’ll use.

Next, you must evaluate the manufacturer's credibility and manufacturing capacity. Is the PCB manufacture skilled enough to design the type you want? You should also negotiate the manufacturing price to ensure it's within your business’s budget.

Other considerations include:

- Your PCB specs and the manufacturing process,

- The manufacturer’s PCB design software,

- Cost of the materials and manufacturing costs,

- Markup and the tooling costs.

- Manufacturer’s per square inch charge.

How to Reduce PCB Cost on Printed Circuit Board

Operating within your budget is essential in the PCB business. So the following cost-cutting measures can be of immense help:

- First, order PCBs with fewer layers if this doesn’t affect the functionality.

- You can also choose cheap materials to make your PCBs. For instance, CEM-3 over FR-4 material is more affordable.

- Likewise, selecting cheaper PCB finishes, such as Tin plating, will significantly help you lower the costs.

- When choosing the design tolerance, we recommend avoiding tight tolerances where possible. It will help your business cut the PCB costs per piece.

- Finally, go for the panel format that costs the least. It's also recommendable to opt for a linear components alignment, which is remarkably cheap.

Wrap Up

As you can see, you need to consider several factors to determine the cost of producing, assembling, and testing a circuit board. While it is possible to input these variables into a cost calculator, the most accurate method is to consult a reputable PCB manufacturer and assembler like OurPCB. So contact us today with your designs and specify your needs to get a free quote. We'll be in touch.

Special Offer: Get $100 off your order!

Email [email protected] to get started!