Contents

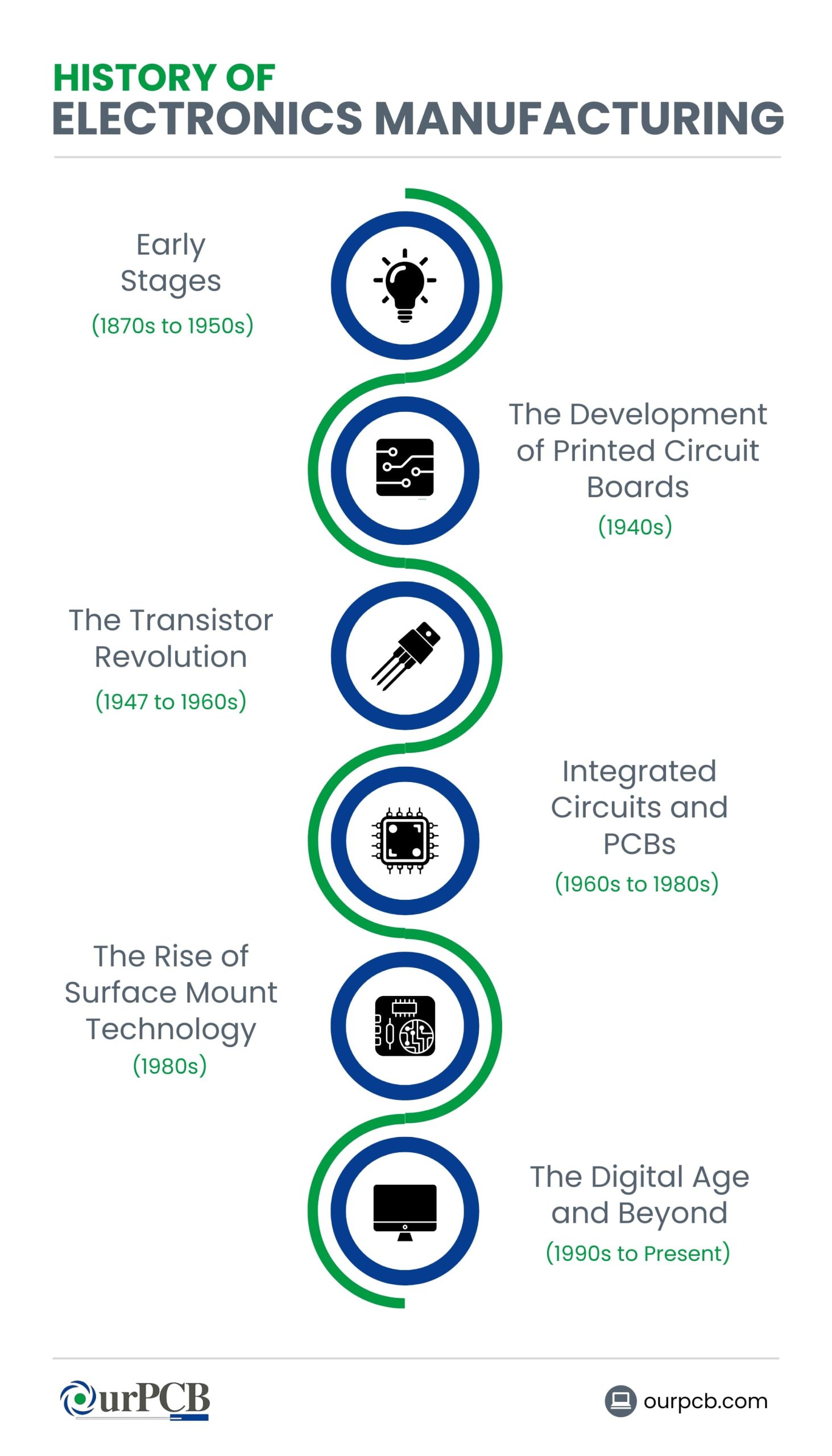

- A Brief History of Electronics Manufacturing

- Early Stages (1870s to 1950s)

- The Development of Printed Circuit Boards (1940s)

- The Transistor Revolution (1947 to 1960s)

- Integrated Circuits and PCBs (1960s to 1980s)

- The Rise of Surface Mount Technology (1980s)

- The Digital Age and Beyond (1990s to Present)

- The Electronic Manufacturing Process

- Design and Prototyping

- Component Sourcing

- PCB Fabrication

- Component Assembly

- Inspection and Testing

- Packaging and Distribution

- Types of EMS

- Electronics Manufacturing Services

- Original Equipment Manufacturer

- Contract Electronics Manufacturer

- Original Design Manufacturer (ODM)

- What are the Advantages of Electronics Manufacturing?

- Cost Savings

- Expertise and Focus

- Flexibility and Scalability

- Accelerated Time-to-Market

- Reduced Waste

- Quality and Reliability

- Challenges of Electronics Manufacturing

- Supply Chain Management

- Intellectual Property Protection

- Demand Forecasting

- Sustainability

- Which Industries Use Electronics Manufacturing?

- Consumer Electronics

- Automotive

- Medical Devices

- Telecommunications

- Aerospace and Defense

- Computing

- Renewable Energy

- Wearable Technology

- How to Choose the Right EMS Partner?

A Brief History of Electronics Manufacturing

The electronic manufacturing industry has evolved dramatically over the past century, transitioning from basic vacuum tube technology to sophisticated integrated circuits and advanced manufacturing techniques.

Early Stages (1870s to 1950s)

The electronic manufacturing industry began in the late 19th century, with inventions like the telephone by Alexander Graham Bell in 1876 and the light bulb by Thomas Edison in 1879. Moreover, the invention of the vacuum tube by Sir John Ambrose Fleming in 1904 was a significant milestone. Early electronic devices relied on these bulky vacuum tubes, which limited their size and efficiency.

The Development of Printed Circuit Boards (1940s)

The development of printed circuit boards (PCBs) began in the 1940s. Austrian engineer Paul Eisler developed the first PCB in 1936. During World War II, PCBs were used in military applications. The U.S. government released PCB technology for commercial use in 1948, and they became much more widely used.

The Transistor Revolution (1947 to 1960s)

In 1947, John Bardeen, Walter Brattain, and William Shockley at Bell Labs invented the transistor, a smaller and more reliable alternative to vacuum tubes. This breakthrough enabled miniaturization and portable electronic devices, fundamentally transforming the electronics manufacturing industry.

Integrated Circuits and PCBs (1960s to 1980s)

Integrated circuits (ICs) were pioneered by Jack Kilby and Robert Noyce in 1958–59. These allowed multiple electronic components to be integrated into a single chip, significantly reducing the size and complexity of electronic devices. PCBs also evolved into more advanced forms, enhancing miniaturization and complexity.

The Rise of Surface Mount Technology (1980s)

Surface mount technology (SMT) was discovered in the 1980s and changed the electronics assembly process by allowing components to be mounted directly onto the surface of PCBs. This removed the need for thru-hole drilling, enabling denser and more reliable circuits and further boosting the performance of electronic devices.

The Digital Age and Beyond (1990s to Present)

The 1990s marked the beginning of the digital age. Personal computers and the internet both became popular and widely used. This period saw massive advancements in chip design, fabrication, and packaging, leading to an explosion in the complexity and capabilities of electronic devices.

Moore's Law, which predicted the doubling of transistor density on ICs approximately every 2 years, held true for decades, driving the rapid miniaturization and increasing power of electronic devices.

Today, electronic manufacturing companies continue to evolve with emerging technologies like 3D NAND, artificial intelligence (AI), and the Internet of Things (IoT) shaping the future of electronics and electronic manufacturing services worldwide. We can look forward to even more sophisticated, interconnected, and intelligent devices.

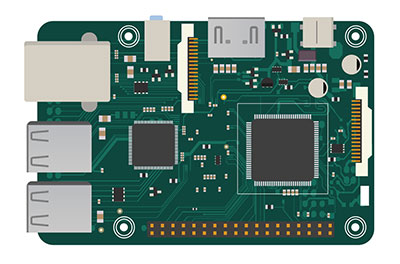

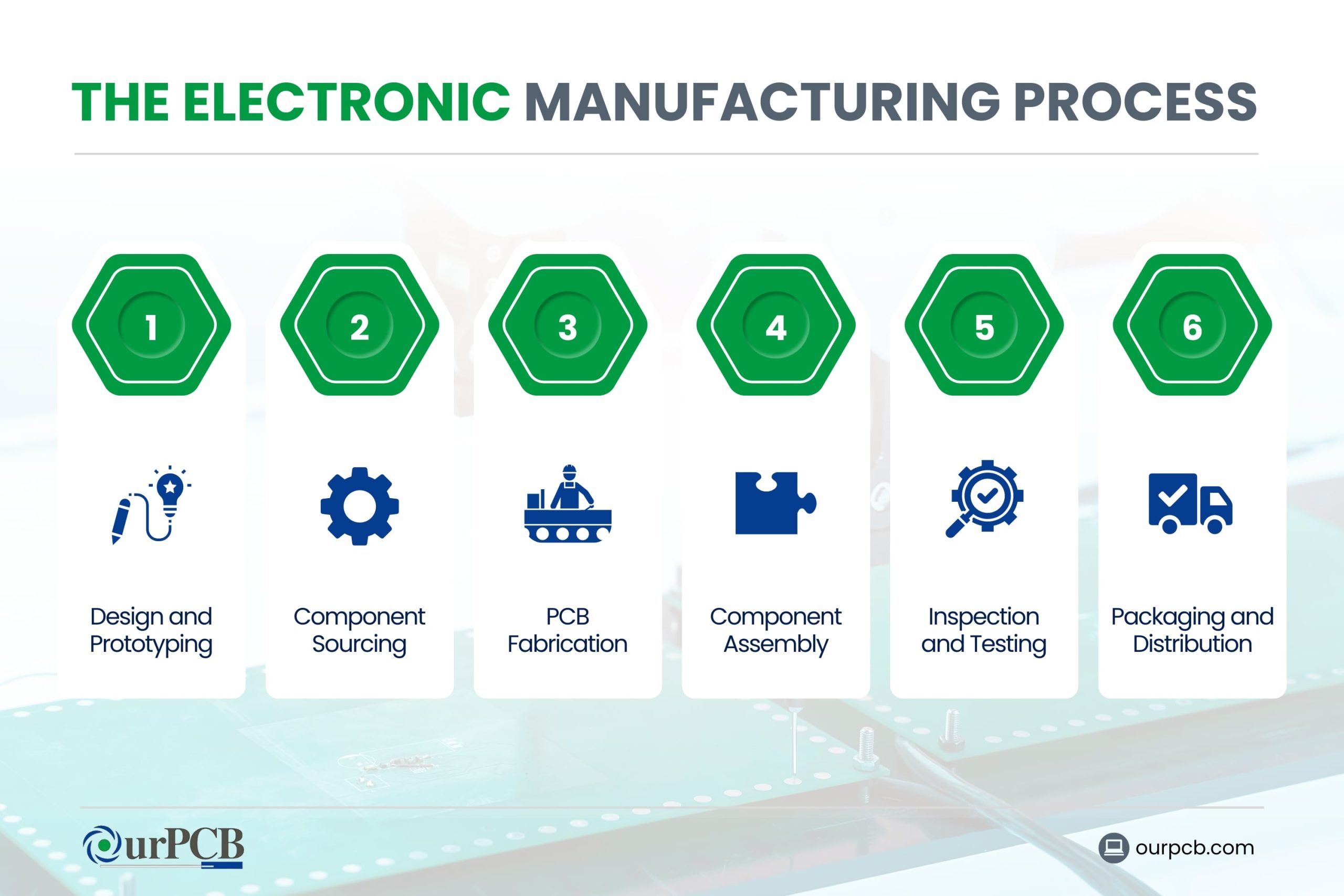

The Electronic Manufacturing Process

The electronic manufacturing process involves several critical stages to transform a concept into a market-ready product. Here's a detailed breakdown of each phase in the electronics manufacturing services workflow:

-

Design and Prototyping

- Product Concept and Specifications: The process begins with defining the product concept and detailed specifications.

- Schematics and PCB Layouts: Engineers design the schematics and create the PCB layouts. This involves configuring the copper arrangement and insulating layers to optimize performance and minimize issues like impedance.

- Software and Firmware Development: Software and firmware are developed to control and operate the electronic device properly.

- Prototyping: Early samples or prototypes are built to test the product’s concept and functionality. Prototyping can involve multiple iterations to refine the product design before full-scale production.

-

Component Sourcing

Electronic manufacturing services must source high-quality components including resistors, capacitors, integrated circuits, and connectors from reliable suppliers. Component availability and cost management are crucial factors in preventing production delays.

-

PCB Fabrication

Manufacturing of Bare PCBs

The process starts with fabricating the bare PCBs. This involves layering and bonding materials like FR-4 (combined fiberglass and reinforced epoxy laminate) to create the board.

Etching

Copper traces are etched onto the boards to form electrical pathways. This process involves removing unwanted copper from the board using chemicals, which creates the desired circuit patterns.

Drilling

Holes are drilled for component leads and vias, to allow for connections between different layers of the PCB.

-

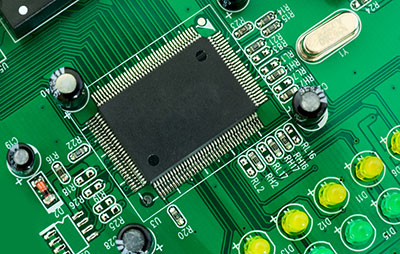

Component Assembly

SMT

Automated pick-and-place machines position components onto the PCB. Solder paste is applied to the PCB pads, and the board is heated in a reflow oven to melt the solder, creating electrical connections.

Through-Hole Technology

Components unsuitable for SMT use through-hole or thru-hole technology (THT). These components are inserted into drilled holes and soldered onto the PCB, typically through wave soldering or manual methods for lower quantities.

-

Inspection and Testing

- Automated Optical Inspection (AOI): Automation processes check for assembly errors by comparing the PCB to the design specifications.

- X-ray Inspection: Verifies the quality of solder joints, especially for complex assemblies like Ball Grid Arrays (BGAs).

- Functional Testing: Makes sure the assembled PCB works as intended, checking electrical performance and identifying any defects or issues.

-

Packaging and Distribution

Packaging

The final products are securely packaged so they stay protected during transportation. Materials like anti-static bags, foam inserts, and sturdy boxes are used to prevent damage from physical jolts, electrostatic discharge, and environmental factors.

Distribution

Electronic manufacturing service providers often offer robust distribution solutions, including warehouse storage, order fulfillment, shipping coordination, and inventory management, ensuring products reach customers quickly and safely.

EMS companies often provide excellent distribution options, as they have strong relationships with shipping companies and can offer extra services like putting kits together or labeling products.

Special Offer: Get $100 off your order!

Email [email protected] to get started!

Types of EMS

The electronics manufacturing industry is vast and contains an option for every need. From electronics contract manufacturing to in-house manufacturing operations, the EMS industry offers a range of options.

Electronics Manufacturing Services

EMS providers offer contract manufacturing services for electronic products. These services encompass PCB design, assembly, testing, and logistics.

They develop the product's blueprint and specifications, checking that every aspect meets the required standards. They will then assemble electronic components into a complete product.

After assembly, rigorous testing is conducted to make sure the product functions correctly and meets quality standards. EMS providers manage the supply chain, which includes procurement and distribution, so the finished products reach the market efficiently.

Original Equipment Manufacturer

OEMs design and market products under their own brand names, focusing on innovation and brand identity. While handling design and marketing internally, they typically outsource manufacturing to specialized electronic manufacturing companies. This partnership allows OEMs to deliver quality products without investing in extensive manufacturing facilities.

Contract Electronics Manufacturer

Like EMSs, Contract Electronics Manufacturers (CEMs) specialize in electronic contract manufacturing of components and assemblies. They provide various services, including PCB assembly, PCB testing, complete product assembly, and finished product testing.

Original Design Manufacturer (ODM)

Original Design Manufacturers (ODMs) design and manufacture products that other companies brand and sell. ODMs make products based on their own designs and then allow other companies to rebrand and market these products under their own names.

This arrangement benefits companies that want to introduce innovative products without investing in the design and manufacturing processes. ODMs play an important role in bringing new products to market efficiently, helping companies to expand their product offerings with minimal investment.

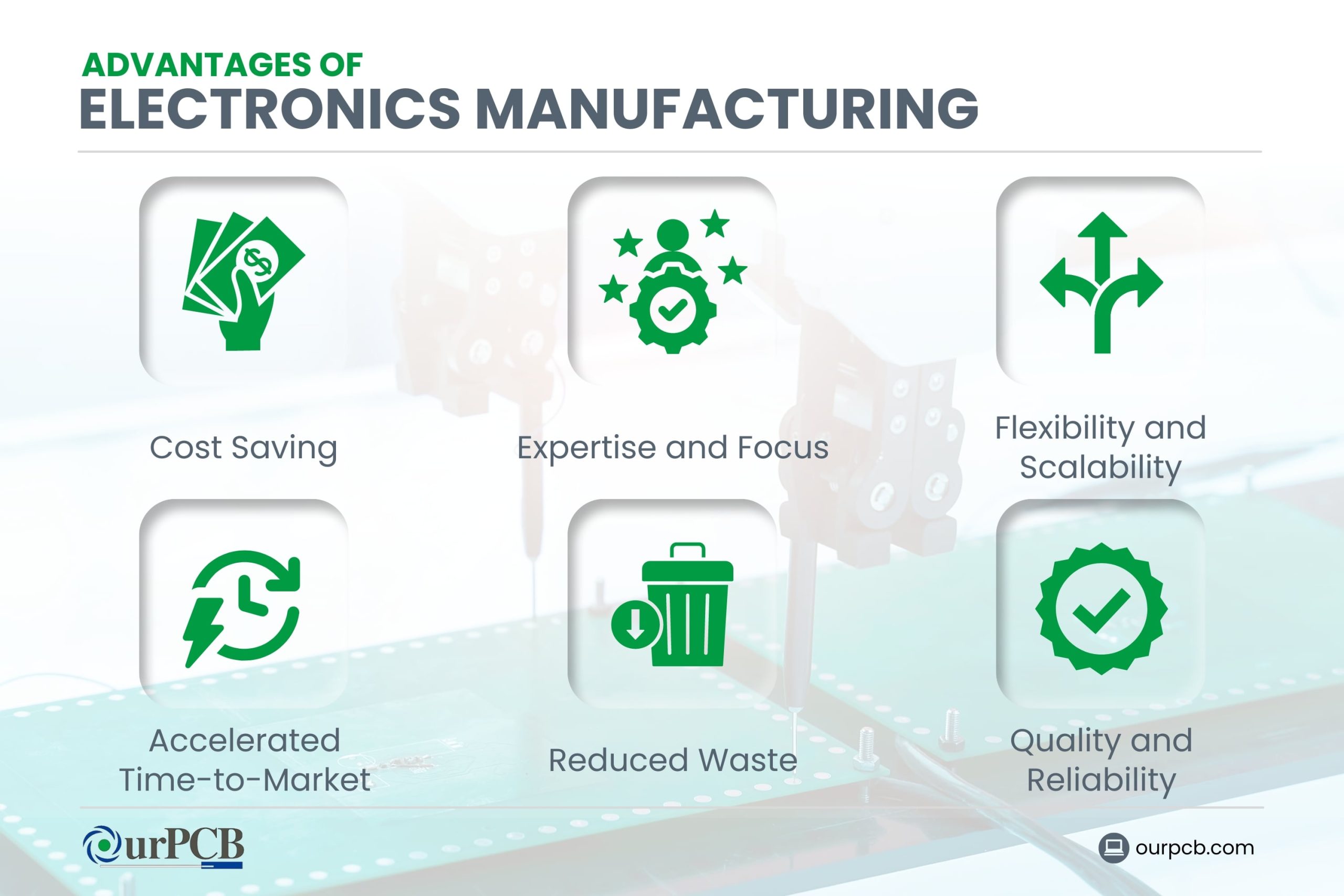

What are the Advantages of Electronics Manufacturing?

Cost Savings

Reduced Overhead

Partnering with electronic manufacturing services providers means businesses don’t need to invest in expensive infrastructure, equipment, and labor. This significantly reduces overhead costs and frees up capital for other business functions.

Economies of Scale

Electronic manufacturing companies leverage large-scale operations to negotiate better prices for components, raw materials, and manufacturing processes. These cost savings translate to more competitive product pricing for their clients.

Expertise and Focus

Specialized Skills

EMS providers employ teams of experienced engineers, technicians, and production specialists with deep expertise in electronic design and manufacturing. Their knowledge ensures high-quality products and efficient production processes.

Focus on Core Business Needs

Outsourcing manufacturing allows businesses to concentrate on their core competencies, like research and development, marketing, and sales, so they can innovate faster and respond effectively to market trends.

Flexibility and Scalability

Customizable Solutions

Flexible manufacturing solutions are tailored to specific product requirements, so businesses can quickly adapt to changing market demands and customer preferences.

Adapting to Demand Fluctuations

Production can be easily scaled up or down to match fluctuating demand. This ensures businesses can meet customer needs without overproducing or facing inventory shortages.

Accelerated Time-to-Market

Rapid Prototyping

Electronic manufacturing services can quickly create product prototypes, allowing businesses to test and refine designs early in development. This accelerated process significantly reduces time-to-market.

Streamlined Production Processes

Efficient production processes, optimized workflows, and supply chain networks speed up manufacturing and lead to faster product delivery, giving businesses a competitive edge.

Reduced Waste

Lean Manufacturing Principles

Electronics manufacturers implement lean principles to minimize waste generation and maximize resource utilization. These practices include eliminating unnecessary steps, optimizing workflows, reducing material waste, and promoting cost savings.

Waste Reduction Initiatives

Active implementation of waste reduction strategies, like optimizing packaging, reusing materials, and disposing of hazardous waste correctly, contribute to environmental sustainability and save money.

Quality and Reliability

Strict Quality Control Measures

Rigorous quality control measures are implemented throughout the entire manufacturing process, including inspections, testing, and audits, to make sure products consistently meet high-quality standards.

Advanced Testing Capabilities

Access to state-of-the-art testing facilities and equipment allows for comprehensive product testing for functionality, performance, and durability. This lowers the risk of defects and failures.

Traceability and Documentation

Electronic manufacturing services maintain detailed records of every production step, including component sourcing, production parameters, and testing results. This documentation provides transparency, accountability, and aids in resolving potential issues.

Challenges of Electronics Manufacturing

Supply Chain Management

- Component Sourcing: Having a reliable supply of high-quality components at competitive prices can be difficult. This is influenced by factors like global shortages, geopolitical events, and fluctuations in demand.

- Lead Times: Long lead times for certain electronics components can delay production and impact time-to-market. This is particularly challenging in industries with rapidly changing technologies.

- Counterfeit Parts: The risk of counterfeit components entering the supply chain is a threat to product quality and reliability. Robust measures to detect and prevent counterfeit parts are important.

Intellectual Property Protection

- Intellectual Property (IP) Protection: Protecting IP, such as proprietary designs and software, is essential in electronics manufacturing. Companies must take steps to safeguard their IP from theft or unauthorized use.

- Data Security: The security of sensitive data, including design files, customer information, and production data, is especially important. Cybersecurity measures are essential to protect against data breaches and unauthorized access.

Demand Forecasting

- Predicting Demand: Accurately forecasting demand for electronic products can be challenging due to rapidly changing market trends, seasonal fluctuations, and unexpected events. Inaccurate forecasts can lead to overproduction or shortages, affecting profit.

- Adaptability: While advanced analytics and forecasting tools can improve accuracy, the electronics industry's dynamic nature requires companies to be agile and adaptable to sudden shifts in demand. This may involve adjusting production schedules, sourcing alternative components, or finding new markets.

Sustainability

- Environmental Impact: Electronics manufacturing has a substantial environmental footprint due to the use of energy, water, and hazardous materials. Companies must adopt sustainable practices, such as reducing waste, using renewable energy sources, and responsibly disposing of electronic waste.

- Social Responsibility: Ethical sourcing of materials, fair labor practices, and safe working conditions throughout the supply chain are major aspects of sustainability in electronics manufacturing. Companies should prioritize social responsibility and uphold ethical standards in their operations.

Which Industries Use Electronics Manufacturing?

Consumer Electronics

The consumer electronics industry heavily depends on electronic manufacturing services for smartphones, tablets, laptops, and home entertainment systems. These products require precise assembly of numerous components to ensure high performance and reliability.

Automotive

This industry uses electronics manufacturing for navigation, infotainment, safety features, and electronic vehicle components, boosting vehicle performance and user experience.

Medical Devices

The medical industry relies on precision electronic manufacturing for diagnostic equipment, patient monitors, and therapeutic devices. These critical applications demand the highest standards of accuracy and reliability to ensure patient safety and effective treatment.

Telecommunications

Network equipment like routers, switches, and mobile devices require robust electronic manufacturing services to handle high data transmission volumes and maintain consistent connectivity. Reliability is paramount in this sector where downtime can have significant consequences.

Aerospace and Defense

Electronic manufacturing supports critical navigation systems, communication devices, and control systems in aerospace and defense applications. These components must meet exceptional standards for reliability and performance in extreme environments.

Computing

Servers, data storage devices, and personal computers depend on electronics manufacturing companies for components that process massive amounts of information quickly and reliably. The constant demand for increased computing power drives continuous innovation in this sector.

Renewable Energy

Solar panels, wind turbines, and green energy storage systems rely on electronic manufacturing services for components that efficiently capture and utilize renewable energy sources. This growing industry benefits from manufacturing expertise that maximizes energy conversion efficiency.

Wearable Technology

The booming wearable device market, including fitness trackers and smartwatches, requires advanced electronic manufacturing expertise to create small, energy-efficient components that operate reliably in everyday conditions.

How to Choose the Right EMS Partner?

- Expertise: Make sure the electronics manufacturing provider has experience and expertise in your specific product type or industry.

- Technology and Equipment: Ask about their technology and equipment capabilities to make sure they can meet your product’s requirements.

- Quality Certifications and Standards: Look for providers with relevant quality certifications (e.g., ISO 9001) and compliance with industry regulations.

- Lead Time and Delivery: Discuss lead times and confirm their on-time delivery track record.

- Supply Chain Management: Evaluate their supplier network and risk mitigation strategies.

- Scalability: Assess their production capacity and flexibility to meet your current and future needs.

- Communication: Establish clear communication channels and ensure responsiveness.

Back to top: Electronics Manufacturing (EMS): The Ultimate Guide

Special Offer: Get $100 off your order!

Email [email protected] to get started!