The OurPCB team created two tables mapping PCB failures into DIY Hobby PCB Failures and Commercial PCB Assembly Manufacturing Failures:

Contents

DIY PCB Failures

DIY failures often stem from improper handling and design errors, while commercial manufacturing failures are more likely related to fabrication defects and large-scale assembly challenges.

| DIY Hobby PCB Failures | Failure causes |

|---|---|

| Physical Damages | Water exposure, dust buildup, accidental drops, oxidation, vibration, heat damage |

| Design Flaws | Incorrect component placement, poor trace design, improper material selection |

| Soldering Defects | Cold solder joints, insufficient solder, bridging, flux contamination |

| Thermal Issues | Overheating due to improper heat dissipation or lack of thermal vias |

| Open/Short Circuits | Misaligned traces or solder bridges causing connectivity issues |

| Copper Issues | Copper traces too thin or too close to board edges |

| Ionic Contamination | Residues from poor cleaning causing corrosion or electrochemical migration |

| Pad Lifting | Pads detaching due to excessive heat during soldering |

| Burned Components | Overheating components due to incorrect power supply or soldering errors |

| Environmental Factors | Heat, dust, moisture exposure during DIY handling |

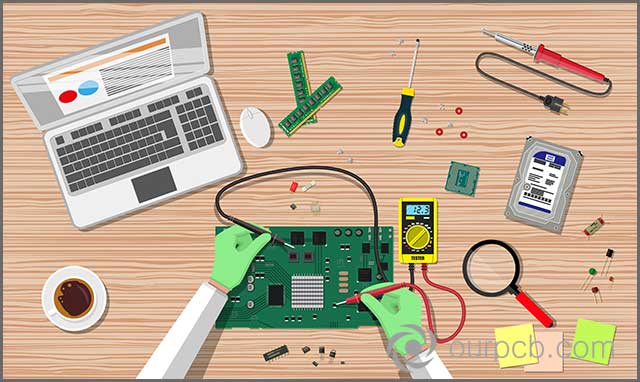

(A technician fixing a broken PCB)

Commercial PCB Assembly Manufacturing Failures

| Failures of Manufactured PCBs | Failure causes |

|---|---|

| Manufacturing Errors | Over-etching, drilling errors, misaligned layers, insufficient clearances |

| Plating Voids (Fabrication) | Holes or gaps in circuit board plating due to deposition issues |

| Acid Traps (Fabrication) | Acid buildup in acute angles during etching |

| Thermal Issues (Design & Assembly) | Starved thermals, overheating due to poor thermal management |

| Electromagnetic Issues (Design) | Poor trace layout causing EMC/EMI problems |

| Soldering Defects (Assembly) | Cold soldering, black pad defects, outgassing |

| Conductive Anodic Filament Formation (CAF) | Electrical failure due to conductive material growth |

| Interconnect Defects (Fabrication) | Separation between copper filler and circuits |

| Measling and Delamination (Fabrication) | White spots or bubbles due to poor lamination |

| Aging (Components) | Component fatigue or breakdown over time |

| Chemical Leakage (Components) | Corrosion or shorts caused by leaked chemicals |

| Mechanical Failures (Assembly) | Warpage, deformation, brittle fractures |

| Electrical Stress Failures | Electrostatic discharge (ESD), dielectric breakdown, overvoltage |

| Packaging Failures (Components) | Cracks or overstressed wire bonds |

| Slivers (Fabrication) | Thin pieces of copper or solder mask causing shorts |

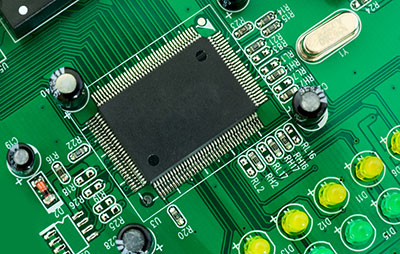

(Electronic circuit board, Setup IC)

Special Offer: Get $100 off your order!

Email [email protected] to get started!

Comprehensive Failure Analysis Techniques

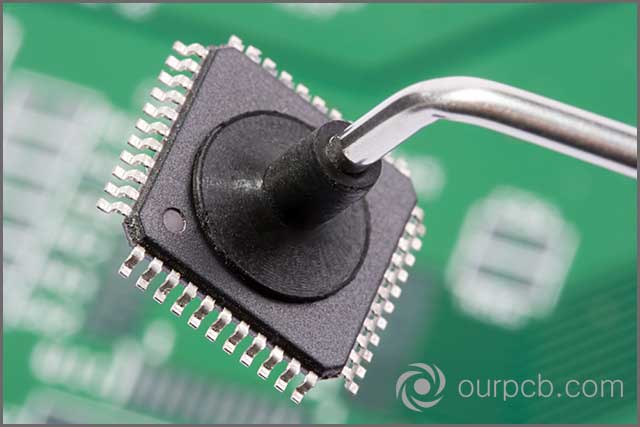

(PCB Failure Analysis)

To address PCB failures effectively, a systematic failure analysis approach is critical:

| Technique | Purpose | Tools Used |

|---|---|---|

| Electrical Testing | Identifies open/short circuits | Probe stations, functional testers |

| Signal Integrity Analysis | Diagnoses waveform issues | Oscilloscopes |

| Emission Microscopy | Detects hotspots from resistance | Infrared cameras |

| Thermal Profiling | Identifies overheating components | Thermal scanners |

| Chemical Analysis | Reveals hidden defects | Chemical etchants |

| Cross-sectioning | Inspects internal layers | Microscopes |

How to Prevent Failures?

| Failure Mode | Prevention Strategy |

|---|---|

| Cracks/Bends | Prebaking, humidity control |

| Polarity Issues | Diode protection, proper labeling |

| Solder Joint Fractures | Automated soldering, visual inspection |

| Corrosion | Thorough cleaning after assembly |

| Short Circuits | Electrical testing, reduced stencil thickness |

| Copper Weight Issues | Follow design specifications |

| Component Misalignment | Accurate pick-and-place machines |

| Low Warranty Components | Source high-quality parts |

| Dewetting | Cleaning and surface preparation |

By following these best practices and leveraging advanced failure analysis techniques, manufacturers can significantly improve PCB reliability while minimizing rework costs and customer dissatisfaction.

References to Internal Links

- For more information on Printed circuit board assembly, visit our detailed guide.

- Learn about flex electronics and their applications.

- Explore our services on PCB manufacturing.

- Check out our PCB trace design guidelines.

- Discover our circuit board solutions.

- Find out about our PCB assembly services and request a prototype.

OurPCB is willing to provide services on PCB and PCBA. You may ask for an online quote or email us to get in touch with our engineers.

Special Offer: Get $100 off your order!

Email [email protected] to get started!