Prototype Cable Assemblies

Prototype cable assemblies are the very important place in between PCB design ideas and interconnects. OurPCB brings prototype assemblies with PCB solutions to your tables.

5 Star Rating on

5 Star Rating on

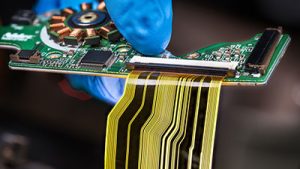

OurPCB offers custom ribbon cable assemblies, including 24 to 48 hour prototyping and automated IDC connector placement systems. Our workshops have automated manufacturing, plus we have copacetic PCB integration services. We make ribbon cable assemblies that beat all of the standards out there.

We remove the need for multi-vendor issues while giving you precise cable design information during your consultation. That also includes automated manufacturing and quality validation.

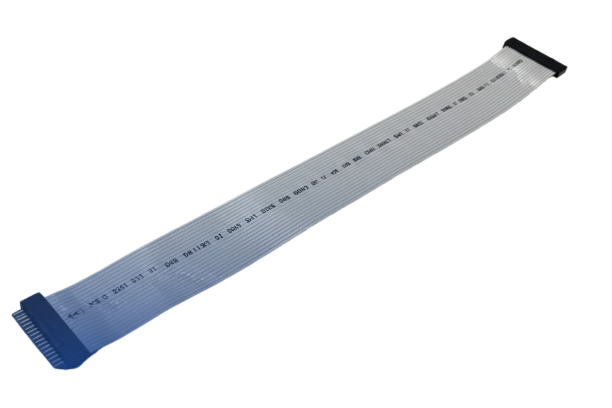

Custom ribbon cable assemblies are really just flat cables with conductors next to each other. These cables have IDC (Insulation Displacement Connector) terminations made for connectivity in a couple of devices that have really tight spaces. The cable assemblies use conductor configurations, from 4 to 80 positions.

The pitch rules are usually between 0.025 inches and 0.156 inches for different kinds of needs. The flat rectangular shape means you can get wire routing in the smallest of spots. You can also do this while keeping signal integrity. This is done through controlled impedance and electromagnetic shielding.

| Pin Count | Common Applications | Pitch Options |

|---|---|---|

| 4, 6, 8, 10 | Simple peripherals | 0.050″, 0.100″ |

| 14, 16, 18, 20 | Computer interfaces | 0.050″, 1.27 mm |

| 24, 26, 34, 40 | IDE connections, hard drives | 1.27 mm, 2.0 mm |

| 50, 60, 64, 80 | High-density electronics | 0.635 mm, 1.27 mm |

Custom ribbon cables provide superior space efficiency, manufacturing cost reduction, signal integrity, and installation reliability compared to traditional round cable solutions widely used in electronics.

test

OurPCB combines advanced automated manufacturing with comprehensive PCB integration services, providing complete electronic assembly solutions with industry-leading quality certifications from our experienced engineering team.

![]()

Our dual 10,000 m² PCB assembly houses in Shenzhen and Shijiazhuang are equipped with high-speed SMT assembly lines capable of placing fine-pitch parts with ±25 µm tolerance.

Each line includes temperature- and humidity-controlled environments, active anti-static systems, and vacuum transport for handling thin or flex printed circuits.

![]()

We are fully certified to ISO 9001, IATF 16949, and IPC-A-610 Class 2 & 3, supporting applications where fine-pitch PCB assembly must meet elevated acceptance criteria for solder joint geometry, lead coplanarity, and component body clearance.

Our QA workflows are built to handle fine-pitch PCBs requiring zero solder bridging and uniform joint fillets across dense arrays.

All assemblies involving ball pitch under 0.5 mm, QFN, or PoP packages undergo X-ray inspection, SPI, and AOI with 15 µm resolution optics.

We detect voids, open leads, insufficient solder, lifted terminations, and hidden shorts. This inspection process is a requirement for successful assembly when working with components that provide no visible solder access.

Every fine-pitch electronic assembly receives a DFM and DFA review focused on stencil coverage, aperture tuning, pcb design limitations, and routing near fine-pitch ICs.

We assist in verifying pad design, thermal pad exposure, and via escape planning, important for high I/O packages like BGA and chip scale layouts where misalignment or solder blockage can compromise yield.

We offer full assembly component sourcing through partners like Digi-Key, Mouser, and WPG, including traceable lots for hard-to-find or moisture-sensitive electronic components.

Components are stored under MSL-compliant conditions, with drying cabinets and vacuum packaging for all incoming fine-pitch parts.

OurPCB manufactures flat cable assemblies with pitch specifications from 0.025 inches (0.635 mm) to 0.156 inches (3.96 mm) including standard 0.050-inch spacing for computer applications. Standard configurations include 0.3 mm FFC for flexible applications, 1.27 mm for IDE interfaces, and 2.0 mm for industrial power applications with various insulation displacement connectors. Connector systems encompass IDC, crimp contacts, and solder terminations with contact resistance below 0.1μΩ for power applications requiring low-resistance connections.

IATF 16949 automotive quality management certification ensures consistent manufacturing processes with full traceability from raw materials through final assembly and test procedures. This standard mandates statistical process control, continuous improvement protocols, and comprehensive documentation systems that meet automotive industry audit requirements. Our certified processes address the demanding requirements of modern vehicles where electrical system failures can impact safety and performance.

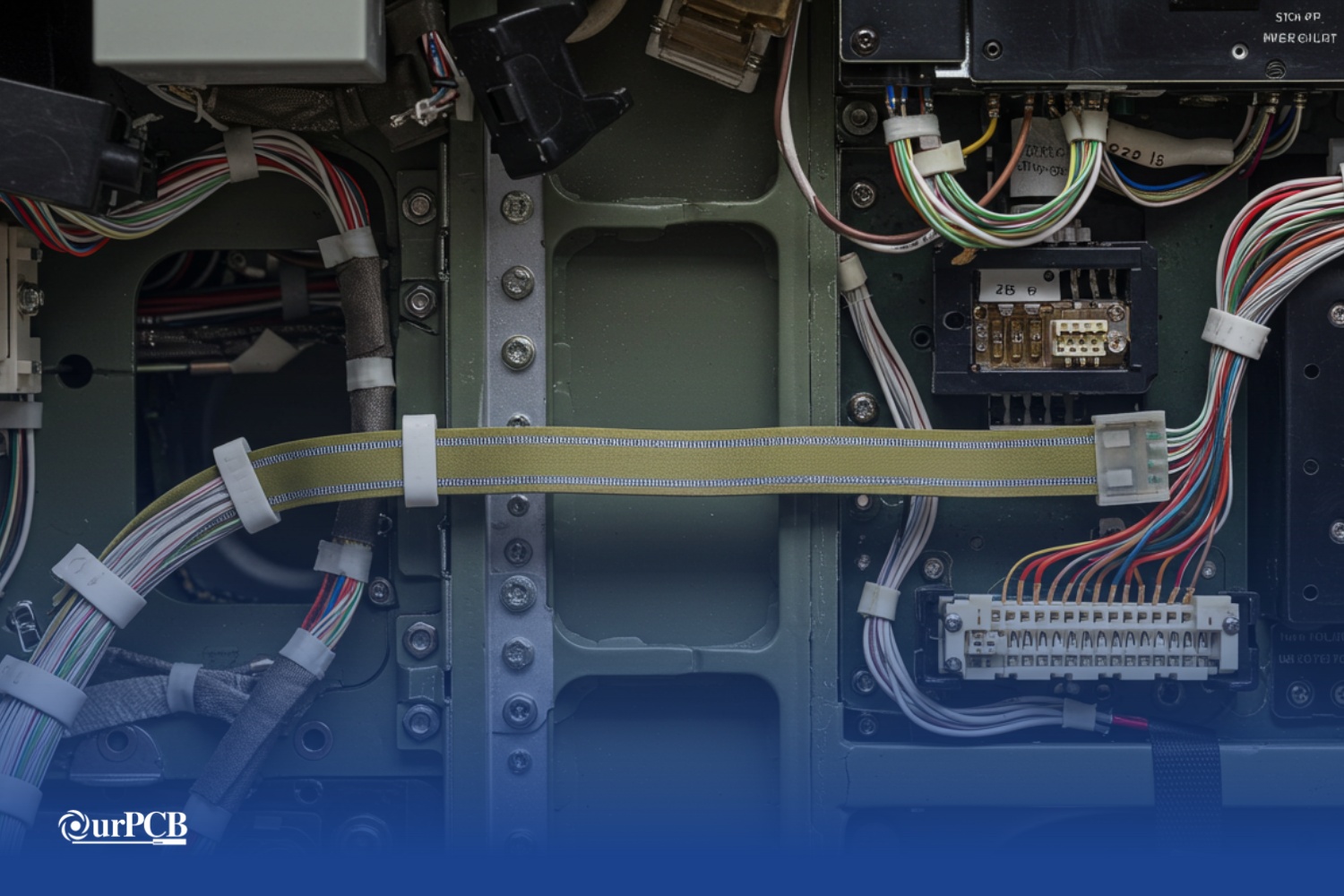

IPC/WHMA-A-620 Class 3 certification establishes the highest reliability standards for wire harness assembly, particularly critical for aerospace and military applications where failure is not acceptable. AS50881 Enhanced Electrical Wiring Interconnection Systems (EWIS) standards govern aerospace applications, specifying fire-resistant materials, reduced weight requirements, and enhanced durability under extreme environmental conditions with complete socket and plug reliability.

ISO 9001:2015 quality management certification provides the foundation for consistent manufacturing excellence across all product lines. RoHS compliance ensures environmental responsibility through elimination of hazardous substances, while UL and CSA certifications validate safety performance for North American market applications including car or truck installations.

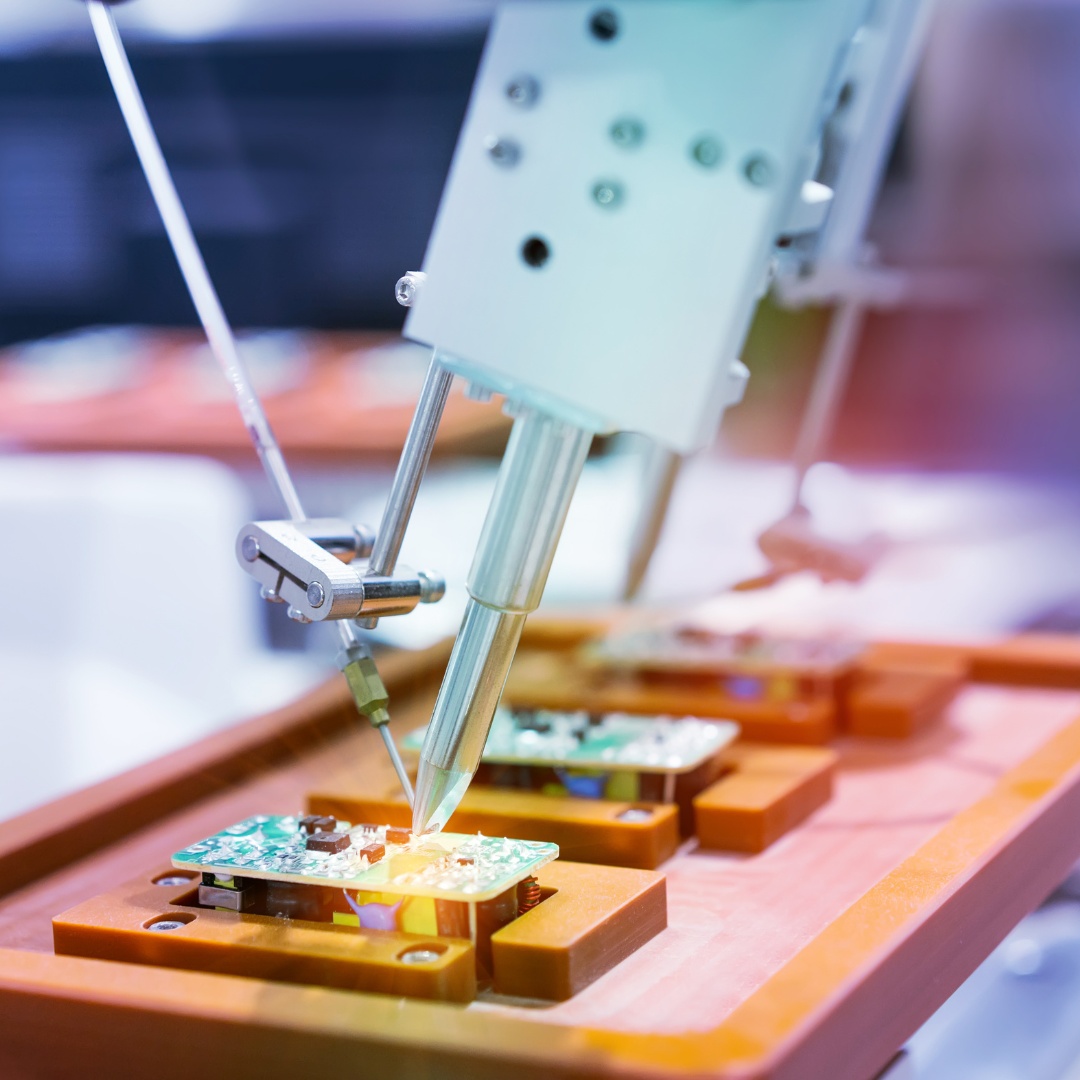

OurPCB utilizes automated assembly lines with robotic placement systems achieving ±0.1 mm positioning accuracy for IDC ribbon connector installation processes. Automated Optical Inspection (AOI) systems perform 100% visual verification of conductor alignment, insulation integrity, and connector seating quality. Contact resistance testing using 4-wire Kelvin measurement validates electrical continuity with specifications below 15mΩ for signal applications requiring precise connections.

OurPCB provides comprehensive PCB assembly solutions specifically designed to integrate seamlessly with custom ribbon cable assemblies as a complete electronics provider. We deliver precision, efficiency, and rigorous quality assurance throughout every stage of the integrated manufacturing process for optimal advantage.

We excel in Surface Mount Technology (SMT) assembly, ideal for high-density and high-performance electronic products requiring ribbon cable connectivity. Our advanced pick-and-place machines ensure accurate component placement with automatic optical inspection verification for critical ribbon cable connection points and planar interfaces.

We provide flexible assembly options matching your project requirements and budget constraints with complete availability tracking. Supply your own components for cost control, or select our turnkey service that includes component sourcing, PCB assembly, and ribbon cable integration with single-source accountability.

Our custom assembly service addresses unique design requirements and specialized applications involving bonded ribbon cable connectivity for complex layouts. We handle intricate configurations and work directly with your engineering team to optimize PCB-to-ribbon cable interfaces for maximum reliability and performance.

We deliver rapid and dependable PCB assembly services with integrated ribbon cable installation for urgent project timelines. Our expedited service provides finished assemblies within accelerated schedules while maintaining strict quality standards and comprehensive testing protocols.

We manufacture PCBs meeting IPC Class 3 certification requirements, essential for aerospace, medical, and mission-critical applications requiring zero defects. These assemblies provide maximum reliability for high-performance systems requiring ribbon cable connectivity with complete quality documentation.

We accommodate all integrated circuit package types with precision assembly capabilities, including BGAs, POPs, CGAs, QFNs, DFNs, and CSPs. Our advanced placement equipment handles complex IC packages while ensuring proper ribbon cable routing and connection accessibility for optimal installation.

OurPCB provides comprehensive electromagnetic interference (EMI) and radio frequency interference (RFI) shielding solutions integrated directly into flat ribbon cable assemblies for sensitive applications. Our shielding options include custom copper mesh wrapping, ferrite core integration, and conductive polymer coatings for applications requiring FCC Class B compliance with superior performance. Shielding effectiveness testing validates attenuation performance from 10MHz to 10GHz frequency ranges, ensuring optimal protection.

OurPCB’s automated manufacturing facility features state-of-the-art equipment capable of processing ribbon cable assemblies with conductor counts from 4 to 80 positions and custom lengths up to 2 meters for various application requirements. Our laser cutting systems achieve ±0.01 mm precision on conductors as fine as 40AWG with automated stripping that maintains consistent insulation removal without conductor damage for optimal performance.

Environmental compliance testing includes RoHS verification, REACH regulation adherence, and conflict mineral reporting for global market compatibility with complete availability tracking. Our quality management system maintains complete material traceability with supplier certifications for all ribbon cable materials, connectors, and insulation components while monitoring critical parameters including conductor spacing, insulation thickness, and connector insertion force to ensure consistent manufacturing quality across all production volumes.

OurPCB eliminates the complexity and delays associated with traditional ribbon cable manufacturers through our integrated manufacturing approach and rapid prototyping capabilities. Our engineering team provides immediate design consultation to optimize your custom ribbon cable specifications for manufacturing efficiency and cost reduction while ensuring complete compatibility with your PCB requirements.

Contact our technical specialists today to discuss your custom cable assembly needs and receive a detailed quote with projected timelines. Visit our custom cable design center to experience the advantage of single-source accountability for both PCB manufacturing and ribbon cable assembly with guaranteed quality standards.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

OurPCB accepts single-unit prototype orders with 24-48 hour delivery timelines, enabling rapid design validation without minimum quantity restrictions. Volume production orders benefit from optimized pricing structures starting at 10 units with progressive cost reductions for quantities exceeding 500 assemblies.

Our automated assembly systems include real-time Statistical Process Control (SPC) monitoring of critical parameters including conductor spacing, connector insertion force, and contact resistance measurements. Every assembly undergoes automated optical inspection with 99.97% defect detection capability, followed by electrical continuity testing and environmental stress validation according to IPC/WHMA-A-620 workmanship standards.

Our engineering team provides comprehensive design review services to optimize ribbon cable integration with your existing PCB layouts, including connector placement recommendations, routing optimization, and signal integrity analysis. We accommodate both IDC connector modifications and custom cable configurations to ensure seamless integration without PCB redesign requirements.

Request a quote and get a custom testing plan tailored to your design, BOM, and inspection needs. We provide PCB testing services with full traceability, calibrated measurement systems, and certified workflows for Class II and Class III assemblies.

Prototype cable assemblies are the very important place in between PCB design ideas and interconnects. OurPCB brings prototype assemblies with PCB solutions to your tables.

PCB thermal management prevents component overheating through strategic heat transfer techniques. Without proper thermal control, electronics are at risk of electronic failures through weakened solder

ContentsKey TakeawaysWhat is a Multilayer-Printed Circuit Board?How do Multilayer PCB Boards Work?Multilayer PCB ApplicationsMultilayer PCB Manufacturing Process: StepsMultilayer PCB Manufacturing MachinesBenefits of Multilayer Circuit BoardsWhat

As electronics continue to miniaturize while processing power increases, the resulting thermal challenges make high-Tg PCBs increasingly essential for modern electronic design. ContentsKey TakeawaysWhat is

Running a computer system requires computer memory. In the entire computer system, it’s one of the vital components. Therefore, it’s important that you have basic

Electronic enthusiasts developing a circuit project may want to think about whether or not they should integrate an FFC vs. FPC. Both cables possess varying

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree