Prototype Cable Assemblies

Prototype cable assemblies are the very important place in between PCB design ideas and interconnects. OurPCB brings prototype assemblies with PCB solutions to your tables.

5 Star Rating on

5 Star Rating on

OurPCB provides end-to-end solutions, handling design, production, and testing to ensure quality and efficiency while reducing costs. Serving clients worldwide and in the USA, we streamline the fabrication process for better control, faster turnaround, and reliable results.

OurPCB is ready to assist from start to finish, including design, fabrication, component sourcing, SMT and through-hole assembly, conformal coating, enclosure, and testing. We handle everything while ensuring quality, efficiency, and a fast turnaround.

We offer both partial and full turnkey PCB assembly services, giving you flexibility based on your needs.

Already have some components? No problem! You can supply specific materials, and we’ll take care of the rest—assembly, quality control, and testing—ensuring a smooth and efficient production process.

Want a completely hassle-free experience? We’ll source everything—PCBs, stencils, and components—so you can focus on your design. Just provide us with your Gerber files and specifications, and we’ll handle procurement, assembly, and final testing.

| Type of Turkey Service | Advantages | Ideal Use Cases |

|---|---|---|

| Partial Turnkey |

|

|

| Full Turnkey |

|

|

Getting familiar with the process can help you understand what to expect and how it works.

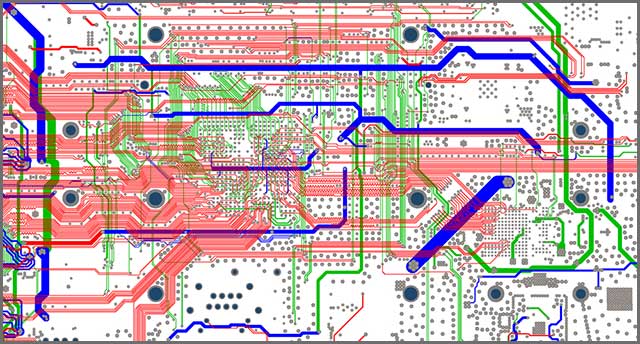

Before production begins, we conduct Design for Manufacturing (DFM) checks to ensure the PCB is optimized for efficient and cost-effective assembly. We require essential design files, including Gerber, ODB++, BOM, NC drill, and pick-and-place files. A thorough design review helps detect manufacturability issues early, avoiding costly delays.

We handle component sourcing by selecting parts based on the BOM, balancing cost, availability, and lead time. Standard components speed up production, while hard-to-find parts may extend timelines. Our trusted supplier network ensures quality parts at competitive prices, helping reduce procurement risks and costs.

Before assembly, we inspect and verify all components and materials to prevent defects. This includes checking for damage, ensuring part compatibility, and verifying inventory levels. Proper preparation ensures smooth production, reduces rework, and enhances final PCB quality by eliminating material-related issues.

Once materials are ready, we begin PCB fabrication, which includes layer stacking, etching, drilling, solder masking, and surface finishing. We also perform quality control checks throughout the process to detect structural or electrical defects. This step ensures the PCB meets design requirements before assembly.

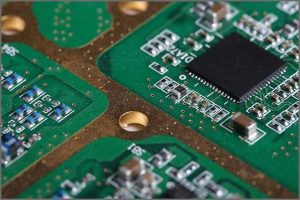

During assembly, we use Surface Mount Technology (SMT) for high-speed, automated component placement. Through-hole assembly is used for components requiring stronger mechanical bonds. Both methods involve soldering, quality inspections, and reflow processes to ensure secure connections and structural integrity.

To maintain high standards, we conduct multiple inspection and testing methods, including AOI, X-ray, ICT, flying probe, and functional testing. These tests identify potential defects before shipment, ensuring reliability, electrical performance, and compliance with industry quality standards.

For PCBs requiring embedded software or firmware, we program microcontrollers, FPGAs, and other ICs to perform their intended functions. Common applications include smart devices, medical equipment, and industrial automation, ensuring seamless integration and device functionality.

To protect the PCB from moisture, dust, and extreme conditions, we apply a thin conformal coating after assembly. This enhances durability, reduces environmental damage, and extends the PCB’s operational lifespan, especially for harsh environments or mission-critical applications.

Before shipping, we perform a final quality check to ensure the PCB is defect-free, fully functional, and meets customer specifications. Boards are packaged in antistatic bags, vacuum-sealed, and moisture-protected to prevent damage in transit, ensuring safe and reliable delivery.

The cost of turnkey PCB assembly varies significantly based on several factors. For a rough estimate, the cost of manufacturing a printed circuit prototype ranges from $10 to $50, depending on size, material, and production labor costs. Assembly costs per square inch can range from $0.02 to $0.05, influenced by necessary assembly labor, labor rates, assembly time, overhead manufacturing expenses, and board design complexity. For the most accurate pcb assembly quote, it’s recommended to consult directly using our free quote form.

The cost of turnkey PCB assembly varies significantly based on several factors. For a rough estimate, the cost of manufacturing a printed circuit prototype ranges from $10 to $50, depending on size, material, and production labor costs. Assembly costs per square inch can range from $0.02 to $0.05, influenced by necessary assembly labor, labor rates, assembly time, overhead manufacturing expenses, and board design complexity. For the most accurate pcb assembly quote, it’s recommended to consult directly using our free quote form.

We handle everything from parts sourcing to final assembly, providing a hassle-free experience that ensures top-quality boards every time.

Whether you need a few prototypes or large-volume batches, our flexible assembly services adapt to your project’s scope and timeline.

Stay environmentally responsible with our compliant assembly processes, offering RoHS and lead-free options for safe, reliable builds.

No matter the complexity, we can assemble boards of all configurations—single-layer, multi-layer, or a mix—to match your exact specifications.

From one-off prototypes to bulk orders, we accommodate projects of all sizes without compromising on quality or turnaround time.

Join our growing community of satisfied clients who rely on our dependable assembly expertise and dedicated customer support.

Only one vendor provides your turnkey services, meaning other suppliers won’t need to get involved in all or a portion of the project. As a result, all the processes are easier to coordinate and manage.

Customers can save with turnkey PCB assembly by relying on cost-effective suppliers. They take advantage of bulk ordering, supply chains, and economies of scale — making them more cost-efficient.

The end product will land on the market much faster due to the faster manufacturing that results from fewer collaborations between vendors.

Meeting consistent quality standards occurs when one supplier takes care of the production process. This also involves regularly focusing on quality control.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

You will want to use turnkey PCB assembly under these conditions:

As a turnkey PCB manufacturer, we anticipate and overcome challenges to ensure a smooth production process. Here’s how we address common obstacles:

A turnkey PCB project can take between 1 and 15 days to assemble. Of course, that length depends on how many components the project needs.

You will need the BoM, centroid data, and Gerber or ODB++ design files.

It’s expensive and hard to modify the design after assembly has started. Those costs decrease if you discuss any changes early.

Prototype cable assemblies are the very important place in between PCB design ideas and interconnects. OurPCB brings prototype assemblies with PCB solutions to your tables.

PCB thermal management prevents component overheating through strategic heat transfer techniques. Without proper thermal control, electronics are at risk of electronic failures through weakened solder

ContentsKey TakeawaysWhat is a Multilayer-Printed Circuit Board?How do Multilayer PCB Boards Work?Multilayer PCB ApplicationsMultilayer PCB Manufacturing Process: StepsMultilayer PCB Manufacturing MachinesBenefits of Multilayer Circuit BoardsWhat

As electronics continue to miniaturize while processing power increases, the resulting thermal challenges make high-Tg PCBs increasingly essential for modern electronic design. ContentsKey TakeawaysWhat is

Running a computer system requires computer memory. In the entire computer system, it’s one of the vital components. Therefore, it’s important that you have basic

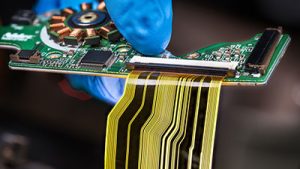

Electronic enthusiasts developing a circuit project may want to think about whether or not they should integrate an FFC vs. FPC. Both cables possess varying

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree