Top 10 Classic Car Wiring Harness Manufacturers | Full Guide

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

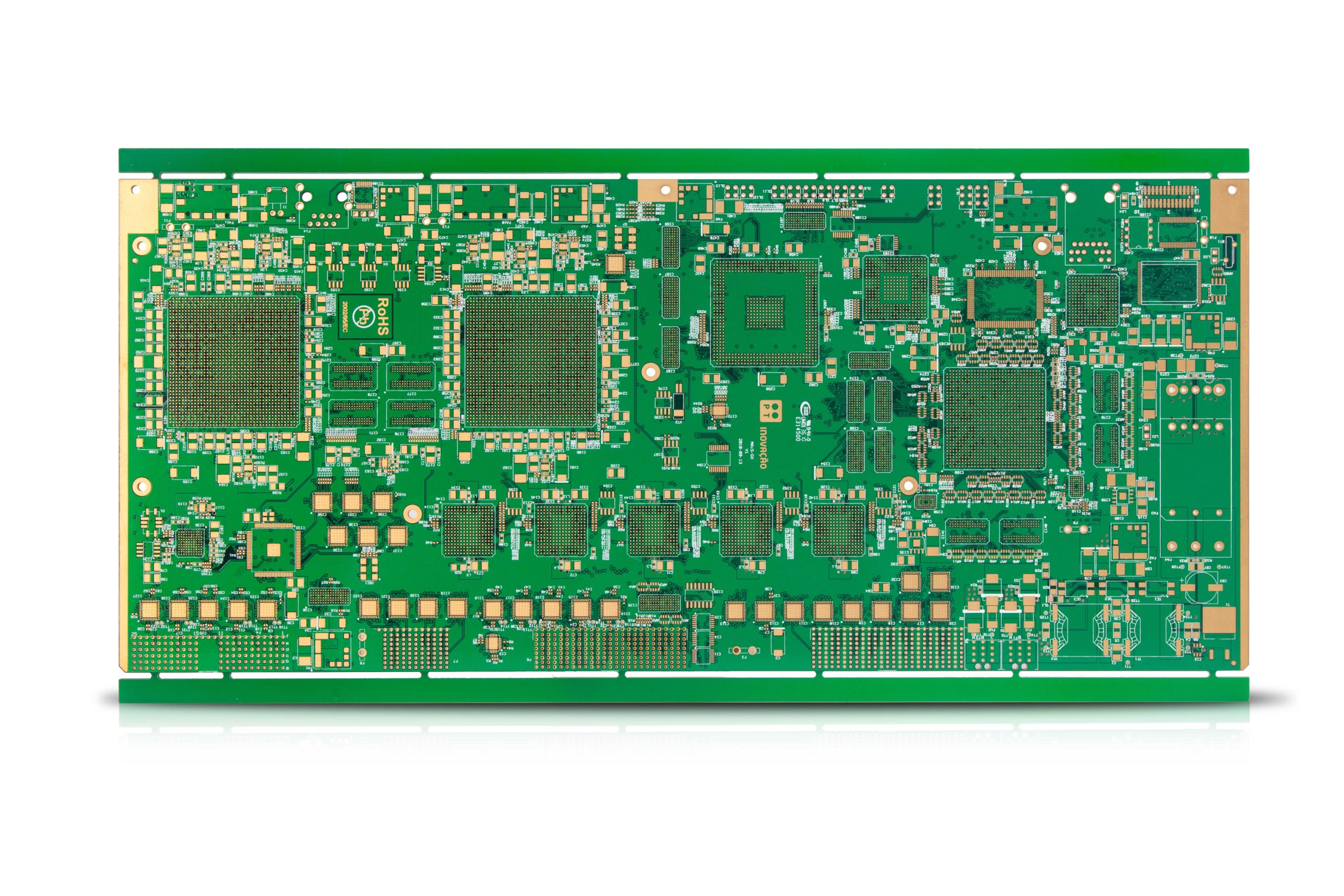

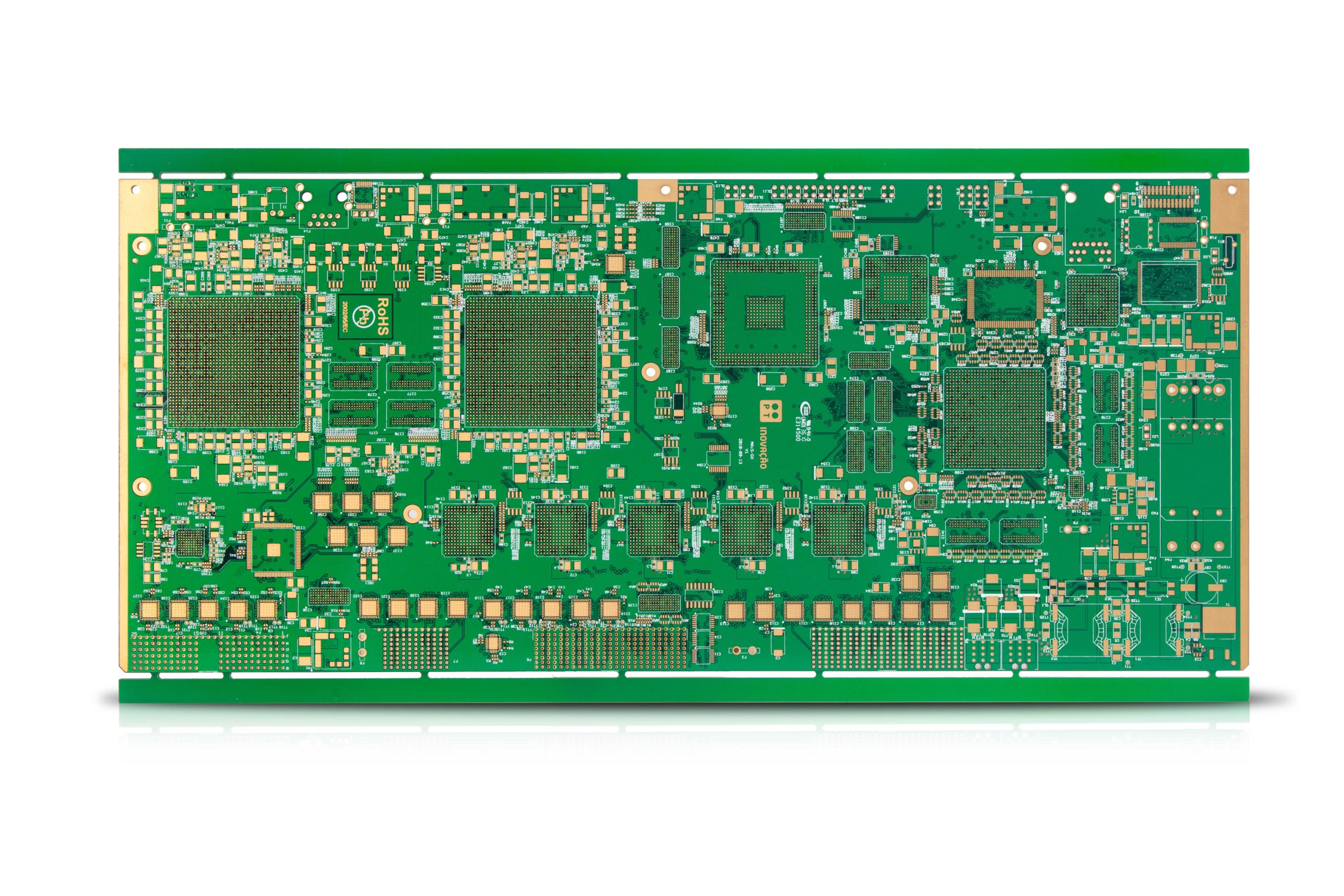

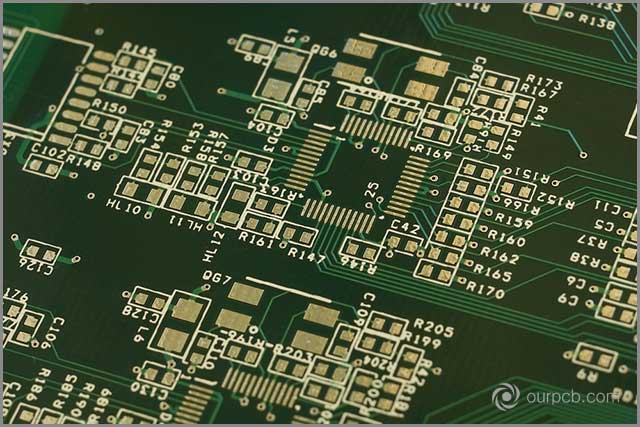

Need Rogers PCB in the USA? OurPCB provides high-quality Rogers PCBs for telecommunications, automotive, RF engineering, aeronautics, and computer systems.

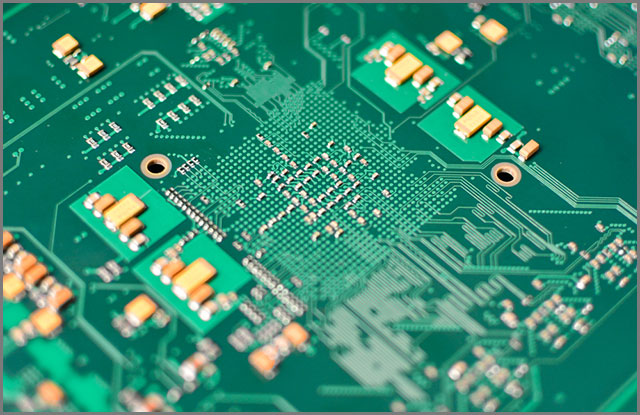

Rogers PCBs offer advanced materials tailored for high-frequency, RF, and microwave applications. Each model provides unique benefits, from low dielectric loss to high thermal stability, making them ideal for industries like telecommunications, automotive radar, and 5G technology. Below is a breakdown of key Rogers PCB models and their applications.

The Rogers 4350B has a low loss capability and stable control on its dielectric constant (DK), makes its materials ideal for high power RF designs and super-active appliances.

This Rogers PCB model is suitable for automotive radar applications with 77 GHz, and it also supports 5G wireless applications and ADAS.

The 3006 model offers excellent mechanical and electrical stability—with a reliable dielectric constant across various temperatures. And it removes the step change in the Dk.

The 3010 is one of the most affordable models with advanced ceramic-filled PTFE materials. Hence, its stability streamlines the broadband components.

Reinforced with glass microfibers, the Rogers 5880 has a low DK and loss feature. Hence, it makes the model highly suitable for broadband and high-frequency applications.

The 6002 model comes with low DK materials that are ideal for sophisticated microwave structures. Hence, it’s ideal for multi-layer board designs.

This RO6010 is ideal for microwave and electronic board applications that require a high DK. Also, the model is ideal—if you plan on dealing with circuit size reduction.

The Rogers 4003 model uses 1674 and 1080 glass fabric styles. All its configurations have the same specifications; they don’t support bromination.

This 4835 laminate is a low-loss material that provides high stability at significant oxidation resistance and increased temperatures. With it, you’ll get a standard glass or epoxy FR-4 processes and cheap circuit production.

This laminate offers a perfect balance of processing capability and performance. Plus, the low-loss laminate consists of hydrocarbon ceramic-filled thermostat materials.

| Property | RO4350B | RO3003 | RO3006 | RO3010 | RO4835 | RO5880 | RO6002 | RO6010 | RO4003 | RO 4360G2 |

|---|---|---|---|---|---|---|---|---|---|---|

| Dk, Process | (2)3.48 ± 0.05 | 3.00 ± 0.04 | 6.15 ± 0.15 | 10.2 ± 0.30 | 3.48 ± 0.05 | 2.20 ± 0.02 | 2.94 ± 0.04 | 10.2 ± 0.25 | 3.38 ± 0.05 | 6.15 ± 0.15 |

| Dk Design | 3.66 | 3.00 | 6.50 | 11.20 | 3.66 | 2.20 | 2.94 | – | 3.55 | – |

| Dissipation Factor | 0.0037 0.0031 | 0.001 0 | 0.002 0 | 0.002 2 | 0.003 7 | 0.0004 0.0009 | 0.001 2 | 0.002 3 | 0.0027 0.0021 | 0.003 8 |

| Thermal Coefficient | +50 | -3 | -262 | -395 | +50 | -125 | +12 | -425 | +40 | – |

| Dimension Stability | – | -0.06 0.07 | -0.27 -0.15 | -0.35 -0.31 | – | – | – | – | – | – |

| Volume Resistivity | 1.2 X 10^10 | 10^7 | 10^5 | 10^5 | 5 x 10^8 | 2 x 10^7 | 10^6 | 5 x 10^5 | 1.7 X 10^10 | 4.0 x 10^13 |

| Surface Resistivity | 5.7 X 10^9 | 10^7 | 10^5 | 10^5 | 7 x 10^8 | 3 x 10^7 | 10^7 | 5 x 10^6 | 4.2 X 10^9 | 9.0 x 10^12 |

| Electrical Strength | 31.2 (780) | – | – | – | 30.2 (755) | 0.96 (0.23) | – | – | 31.2 (780) | 784 |

| Tensile Modulus | 16,767 (2,432) 14,153, (2,053) | 930 823 | 1498 1293 | 1902 1934 | 7780 (1128) | 1070 (156) 450 (65), 860 (125) 380 (55) | 828 (120) | 931 (135) | 19,650 (2,850) 19,450 (2,821) | – |

| Property | RO4350B | RO3003 | RO3006 | RO3010 | RO4835 | RO5880 | RO6002 | RO6010 | RO4003 | RO 4360G2 |

|---|---|---|---|---|---|---|---|---|---|---|

| Tensile Strength | 203 (29.5) 130 (18.9) | – | – | – | 136 (19.7) | – | – | 17 (2.4) | 139 (20.2) 100 (14.5) | 131 (19) 97 (14) |

| Flexural Strength | 255 (37) | – | – | – | 186 (27) | – | – | 4364 (633) | 276 (40) | 213 (31) 145 (21) |

| Dimensional Stability | <0.5 | – | – | – | <0.5 | – | – | – | <0.3 | – |

| Coefficient of Thermal Expansion | 10 12 32 | 17 16 25 | 17 17 24 | 13 11 16 | 10 12 32 | 31 48 237 | 16 16 24 | 24 24 24 | 11 14 46 | 13 14 28 |

| Tg | >280 | – | – | – | >280 | – | – | – | >280 | >280 |

| Td | 390 | 500 | 500 | 500 | 390 | 500 | 500 | 500 | 425 | 407 |

| Specific Heat | – | 0.9 | 0.86 | 0.8 | – | – | 0.93 (0.22) | 1.00 (0.239) | – | – |

| Thermal Conductivity | 0.69 | 0.50 | 0.79 | 0.95 | 0.66 | 0.22 | 0.60 | 0.78 | 0.71 | 0.75 |

| Moisture Absorption | 0.06 | 0.04 | 0.02 | 0.05 | 0.05 | 0.02 | 0.02 | 0.05 | 0.06 | 0.08 |

| Density | 1.86 | 2.1 | 2.6 | 2.8 | 1.92 | 2.2 | 2.1 | 3.1 | 1.79 | 2.16 |

| Copper Peel Strength | 0.88 (5.0) | 12.7 | 7.1 | 9.4 | 0.88 (5.0) | 31.2 (5.5) | 8.9 (1.6) | 12.3 (2.1) | 1.05 (6.0) | 5.2 (0.91) |

| Flammability | (3)V-0 | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 | 94V-0 | N/A | V-0 |

| Lead-Free Process Compatible | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | – |

We handle everything from parts sourcing to final assembly, providing a hassle-free experience that ensures top-quality boards every time.

Whether you need a few prototypes or large-volume batches, our flexible assembly services adapt to your project’s scope and timeline.

Stay environmentally responsible with our compliant assembly processes, offering RoHS and lead-free options for safe, reliable builds.

No matter the complexity, we can assemble boards of all configurations—single-layer, multi-layer, or a mix—to match your exact specifications.

From one-off prototypes to bulk orders, we accommodate projects of all sizes without compromising on quality or turnaround time.

Join our growing community of satisfied clients who rely on our dependable assembly expertise and dedicated customer support.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

| Factor | FR-4 Material | Rogers Material |

|---|---|---|

| Dissipation Factor (DF) | 0.020 | 0.004 |

| Price | Affordable | Expensive |

| Thermal Management | Does not handle high temperatures well. | Excellent high-temperature management. |

| Performance | Decent | Remarkable |

| Dielectric Constant (DK) | 4.5 | 6.15 to 11 |

| Impedance Stability | Lower polarity; does not stabilize charges well. | Higher polarity; stabilizes charges effectively. |

| Applications | Not ideal for space applications (poor outgassing tolerance). | Suitable for space applications due to reduced outgassing. |

Rogers material is preferred for high-frequency applications due to its low dissipation factor (DF) and stable dielectric constant (DK), which improve signal integrity.

Rogers material is engineered for superior thermal management, impedance stability, and high-frequency performance, making it more costly than standard FR-4.

If cost is a primary concern and the application does not require high-frequency performance or extreme temperature resistance, FR-4 is a good choice.

Rogers PCB offers several advantages, making it ideal for high-performance applications:

Rogers PCB offers superior impedance control and stable dielectric properties, ensuring minimal signal loss at high frequencies.

Yes, its low thermal expansion and excellent stability make it more durable in extreme environments.

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

Would your car be able to run without wire harnesses? Not a chance. Wire harnesses connect all the electrical parts together. No harness means no

Making wire harnesses isn’t complicated. At OurPCB, we create custom wire harnesses for an expansive range of industries every day. While it’s a complicated process,

Prototype cable assemblies are the very important place in between PCB design ideas and interconnects. OurPCB brings prototype assemblies with PCB solutions to your tables.

PCB thermal management prevents component overheating through strategic heat transfer techniques. Without proper thermal control, electronics are at risk of electronic failures through weakened solder

ContentsKey TakeawaysWhat is a Multilayer-Printed Circuit Board?How do Multilayer PCB Boards Work?Multilayer PCB ApplicationsMultilayer PCB Manufacturing Process: StepsMultilayer PCB Manufacturing MachinesBenefits of Multilayer Circuit BoardsWhat

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree