Professional engineer review; strict quality control for each process.

Advanced Testing Technology To Ensure the Quality such as AOI Test, E-Test, X-RAY, Impedance Control.

We committed to helping customers get the highest quality products and services with competitive prices (especially multilayers PCBs).

Fast & Accurate

✅ Over 3,000 happy customers

✅ Prototypes and full PC board assembly

✅ RoHS and lead-free assembly

✅ Small quantities available

✅ Single-sided, double-sided, or mixed

Get Free Quote Today!

Welcome to OurPCB Assembly Service

We’ve been offering printed circuit board assembly services since 2007 and have worked with over 3,000 happy customers. OurPCB is your one-stop solution for PCB manufacturing and assembly, dedicated to bringing you the best circuit board assembly possible.

Expert circuit board assembly is key to bringing your product to market as fast as possible. We’re not just dedicated to helping you create products – we’re committed to helping you grow your business by partnering with PCB manufacturing and assembly professionals.

PCB Assembly Services We Offer

Our state-of-the-art equipment and technology allow us to provide a seamless assembly experience no matter what you need.

✔️ SMT, THT, and mixed technology

✔️ Automated process for precision

✔️ Detailed inspection and quality control

✔️ Functional testing

✔️ Fast turnaround times

✔️ From 25 to 5,000 units

✔️ Quick turnaround (1 to 7 days)

✔️ Rigorous checking and testing

✔️ All component sizes

✔️ Leaded or lead-free solder

✔️ 24-hr to 7-day turnaround time

✔️ Fabrication and assembly

✔️ Low- to high-volume

✔️ RoHS-compliant circuit boards

✔️ Rapid prototyping

✔️ Design and assembly

✔️ Quality component sourcing

✔️ Electrical safety testing

✔️ Fortify existing cables

✔️ Off-the-shelf cables available

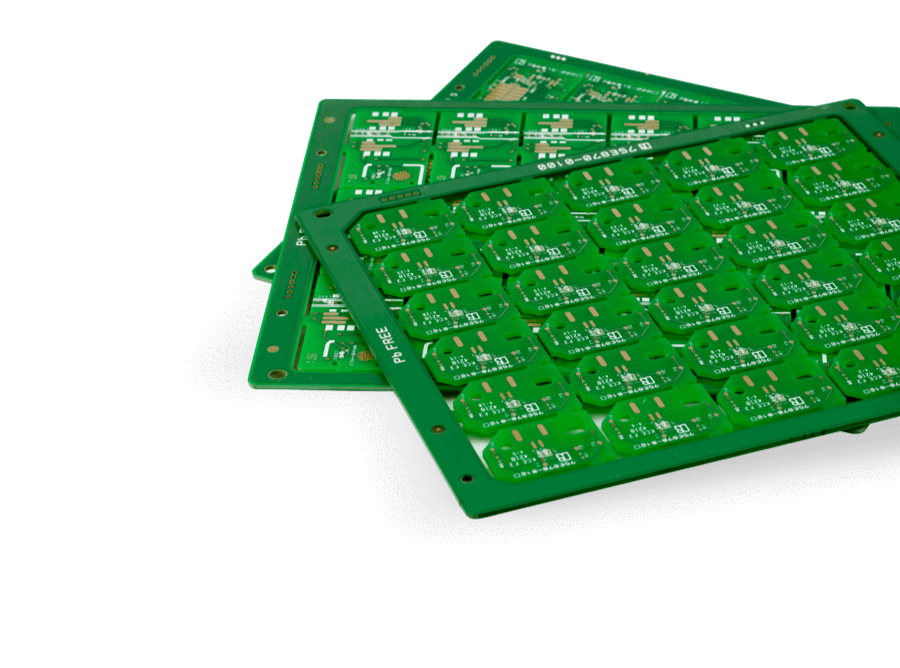

OurPCB Assembly Capabilities

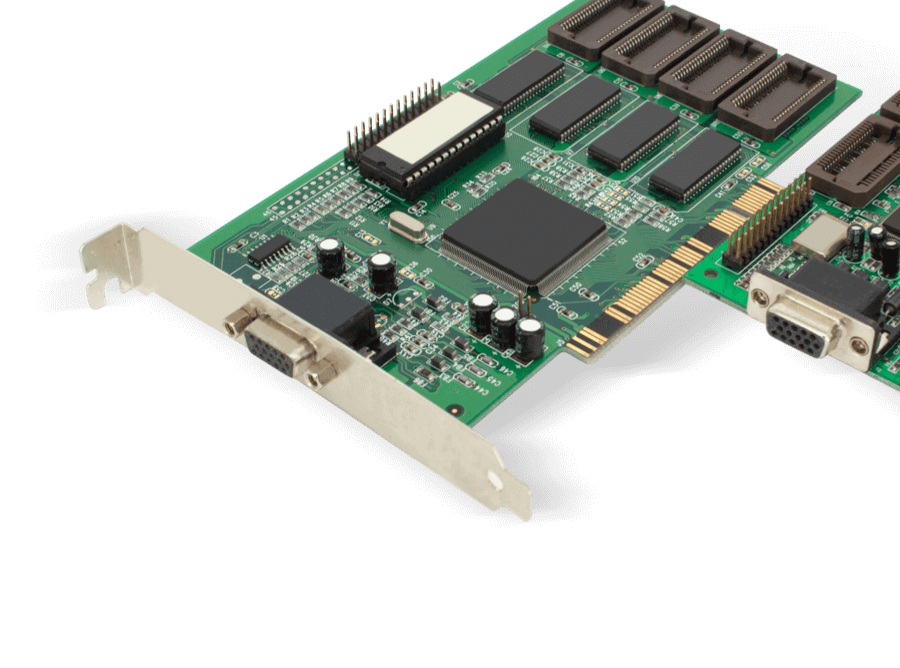

Single- or Double-Sided Mixed Technology Assembly

Consigned Components or Turnkey

All Types of BGAs, CGAs, QFNs, DFNs, CSPs and SONs

Small Quantities and Quick Turns Available

PCB Fabrication or Bare Board PCB Assembly Service

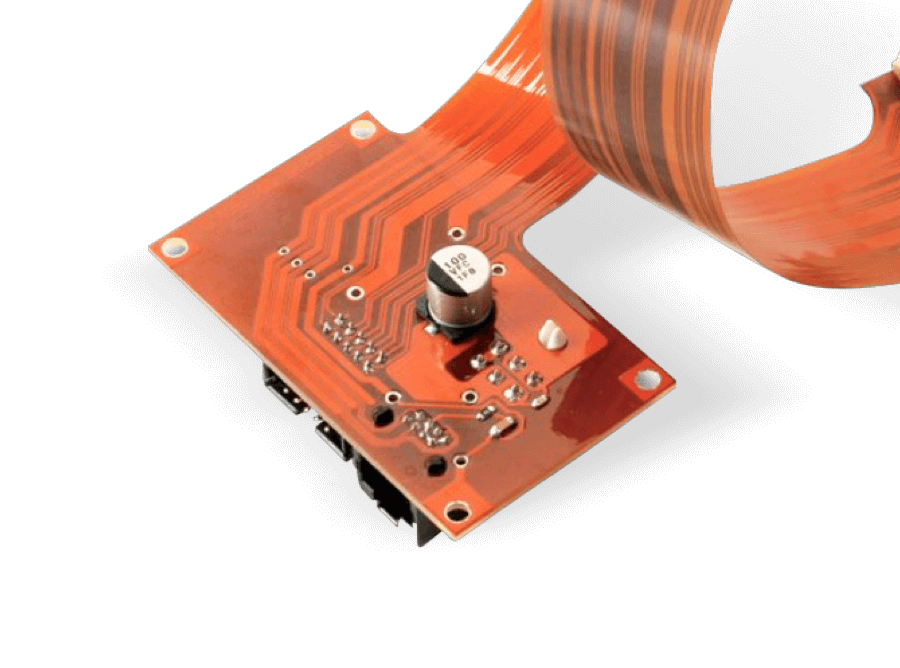

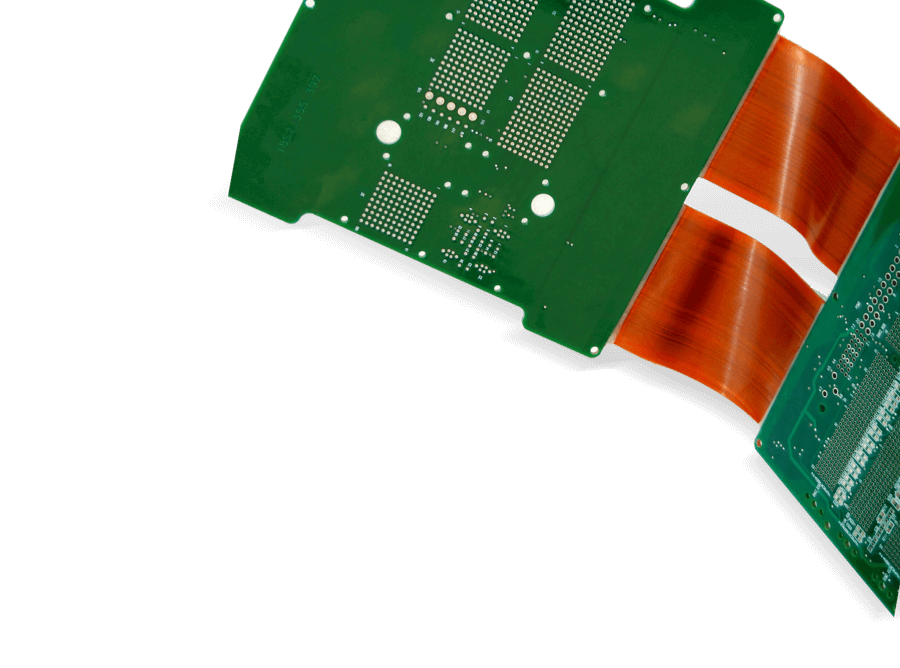

Flexible, Rigid, and Rigid-Flex Assembly Capabilities

Rigorous Testing and Inspection

Prototype Manufacturing and Assembly

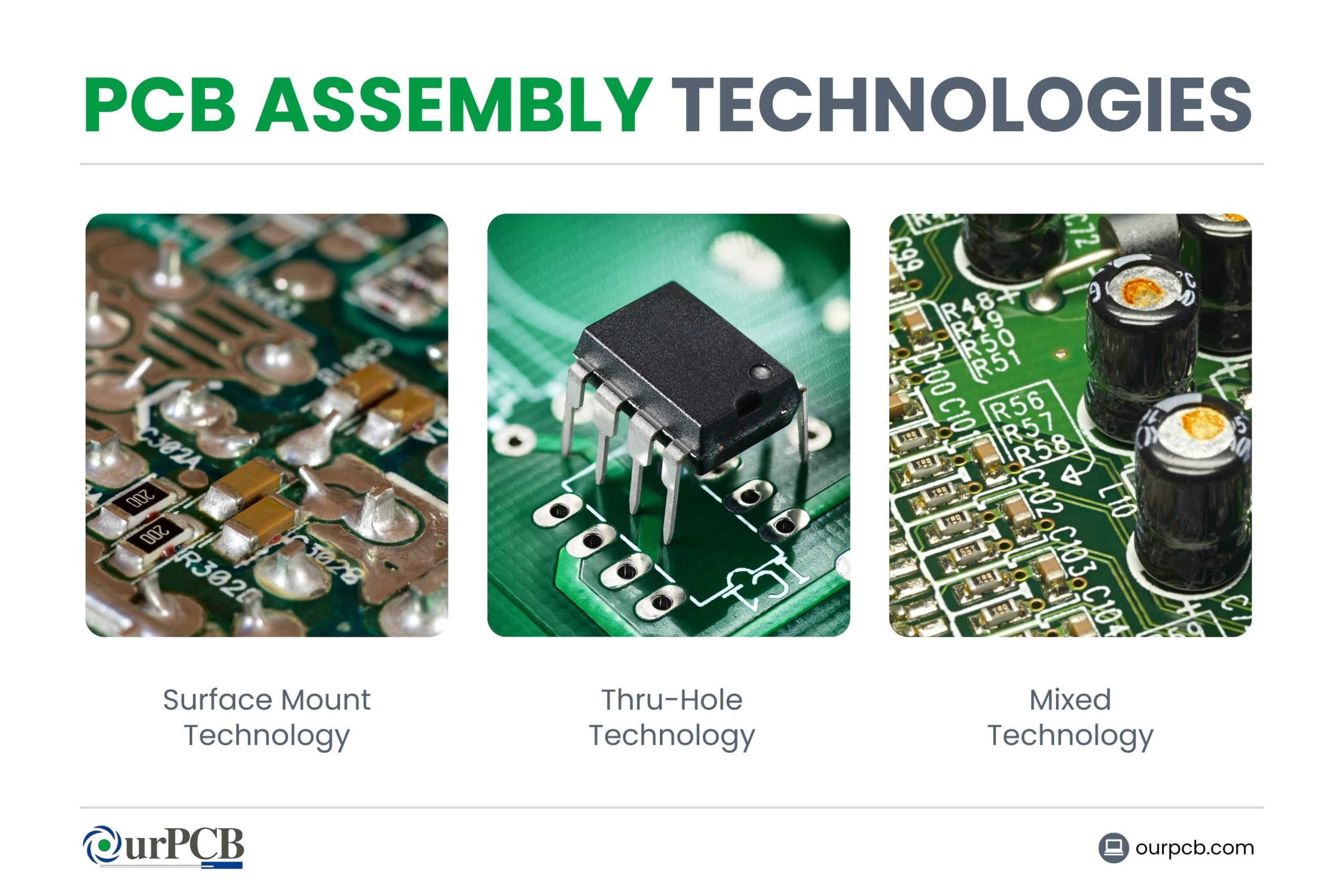

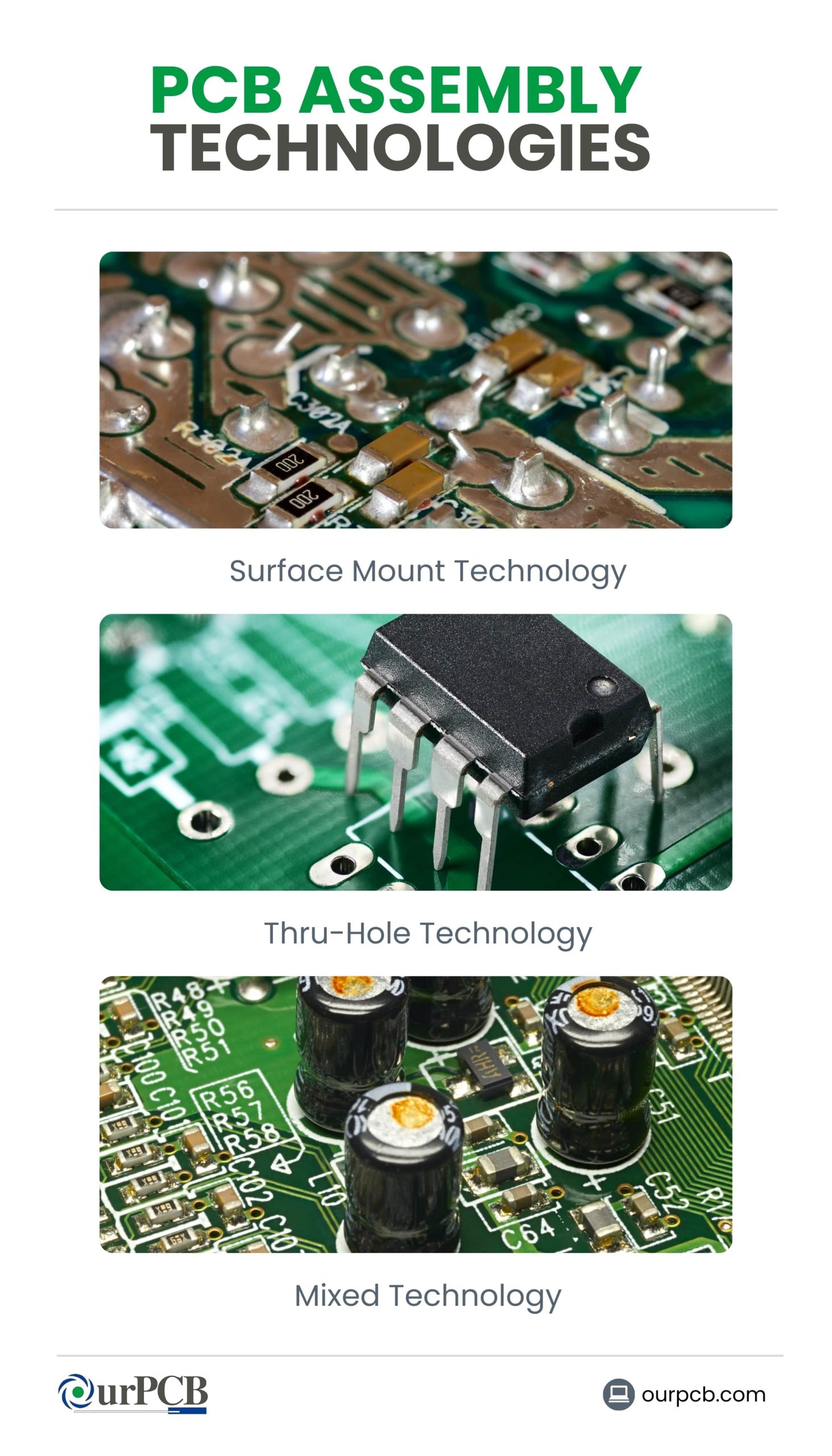

PCB Assembly Technologies

Surface Mount Technology (SMT)

Surface Mount Technology is a method of electronic assembly where components are mounted directly onto the surface of a printed circuit board. SMT assembly allows for smaller, more complex designs and increased production efficiency.

A stencil is used to apply solder paste to the specific areas on the PCB where the components will be placed. Automated pick and place machines accurately position the components on the SMT pads, and the PCB goes through a reflow oven to melt the solder and attach the components.

Through-Hole Technology (THT)

In the through-hole assembly method (also called thru-hole technology), components have leads or pins that are inserted through holes drilled in the PCB. These leads are then soldered to pads on the opposite side of the board, creating a secure electrical and mechanical connection.

THT connections are generally more robust and durable than SMT connections. This makes them ideal for components that experience mechanical stress or high currents.

Mixed-Technology Assembly (MTA)

Mixed-Technology Assembly in PCBs refers to the process of combining both SMT and THT components on the same printed circuit board. Mixed assembly leverages the advantages of both technologies to create more versatile and efficient electronic devices.

This flexible and reliable approach to PCB design and manufacturing allows for the creation of complex electronic devices with improved performance, reduced size, and lower costs.

Electronic Component Sourcing Options

Turnkey

The turnkey electronics manufacturing provides turnkey components. Opting for turnkey PCBA means you don’t need to source or procure the components yourself, saving both time and effort. OurPCB partners with trusted providers for a fast turnkey PCBA service, so you can be sure you’re getting high-quality parts when you work with us.

Consignment

Consignment components are provided to a contract manufacturer (CM) by the original equipment manufacturer (OEM) for assembly into the final product. The OEM retains ownership of these components until they are incorporated into the finished product and sold to the end customer.

Hybrid

Mixing consignment and turnkey PCB assembly is a hybrid approach that allows for greater flexibility and customization in the manufacturing process. The OEM provides certain components (consignment) while the CM procures the remaining components and handles the entire assembly process (turnkey).

How We Test Our PCB Assemblies

Automated Optical Inspection (AOI)

Automated Optical Inspection is a non-contact, automated visual inspection method used to check printed circuit board assembly. It uses high-resolution cameras and image-processing software to detect defects and inconsistencies in PCB production.

High-intensity light sources illuminate the PCB from various angles to enhance the visibility of components and solder joints. Then, high-resolution cameras capture detailed images of the PCB surface from various angles.

Specialized software aligns the captured images with a reference model of the PCB design. Deviations from the expected standards are then flagged as potential defects.

X-Ray Inspection

This is a non-destructive testing method that uses X-rays to visualize the internal structure of a PC board. It works by analyzing the difference in X-ray absorption rates of various materials within the PCB.

Different materials within the PCB absorb the X-rays at varying rates. Denser materials like solder and metal components absorb more, while less dense materials like fiberglass and plastic absorb less.

A detector on the other side of the PCB captures the X-rays that pass through. The resulting X-ray image reveals the internal structure of the PCB, including solder joints, component placement, traces, and potential defects like voids, shorts, or misalignment.

Functional Testing

Functional testing, also known as FCT (Functional Circuit Test) verifies the overall functionality and performance of the completed PCB. It goes beyond testing individual components and focuses on how the entire board operates as a system in its intended environment.

A custom test process is designed to simulate an environment that closely mimics real-world operating conditions. It’s an indication of how well the circuit board will perform in its real environment. Changes can be made if the board performs poorly under functional testing.

Why Choose OurPCB Assembly Services?

Our services are designed to exceed your expectations. Here’s why OurPCB is the ideal PCB assembly and manufacturing partner.

Trusted by over 3,000 Customers

We’ve provided over 3,000 happy customers with cost-effective PCB assembly services. You could be next!

20+ Years in the PCB Business

We’ve been a one-stop PCB assembly service for over 2 decades. Our capabilities are built on years of industry expertise.

RoHS and Lead-Free PCB Assembly Services

Our exceptional PCBs and our electronic manufacturing processes meet all safety standards.

Fast Assembly Lead Time

OurPCB is committed to validating, fabricating, assembling, and shipping your finished products with rapid turnaround times.

Fully Equipped PCBA Factories

We’re proud to own two ISO 9001:2015 certified PCB assembly factories; one in Shenzhen and one in Shijiazhuang.

Top-Class Component Partners

We work with only the best suppliers to provide you with durable, high-quality parts that perform.

Excellent Customer Service

We’re committed to providing you with the best service possible, even after you’ve received your product. Contact us at any time for help from our experts.

Your One-Stop PCB Shop

Whether you need a PCB prototype, component sourcing, or full-scale production, we can help. We’re your one-stop solution for all your PCB needs.

Get a quote today (for FREE) and let’s get your project on the road to the market. OurPCB will be your partner every step of the way, from prototype to full-scale production.

OurPCB’s Additional PCB Services

Design for Assembly (DFA) Review

Our capabilities include a comprehensive review of your design for potential flaws or problems.

Component Sourcing Service

We’ve partnered up with reliable suppliers to source even hard to find components within just a few working days.

Conformal Coating

A thin polymeric film designed to protect components from damage caused by environmental factors.

Surface Texturing

Specific patterns, roughness, or structures on the surface enhance the PCB’s performance, reliability, and functionality.

Prototyping

We offer prototype PCB assembly services to validate, iterate, and optimize designs before going to market.

Box Build Assembly

The entire process of assembling a final product within its enclosure or housing.

Get an instant online quote NOW and get $100 off your PCBA order! This is just another way we’re committed to providing the best PCB quick turn assembly service for every customer.

Turnkey Assembly Case Study

Ready to Bring Your PCB to Life?

Get your online quote now – $100 off your first order with us! If you don’t have a Gerber file yet, contact us anyway. We’ll help you design the perfect PCB.

Industries We Serve

Circuit boards play a huge role in almost every industry. Thanks to our various assembly capabilities and the other PCB services we offer (such as manufacturing, designing, and testing), we’re proud to provide PC boards for these industries and more.

See OurPCB Assembly Factories in Action!

Take a virtual tour through our fully equipped PCBA factories. Our Shijiazhuang factory offers advanced PCB assembly capabilities, running 5 SIEMENS SMT lines operated by over 200 skilled and dedicated staff members.

Our Shenzhen factory focuses on standard PCB assembly processes. This factory runs 7 YAMAHA SMT lines, and has 3D X-ray and AOI capabilities for precise testing. The 110 staff have years of expertise and can handle all your manufacturing needs.

Our factories and talented staff are the heart of our PCB assembly services. Combined with our cutting-edge equipment, we’re ready to bring your circuit boards to life and get them to market as fast as possible.

Back to top: PCB Assembly

Had a run of PCBs created for our school. Used kicad Gerber files which matched perfectly with their online system . Couldn't believe how easy the process was. Fast turn around and the PCBs are of very high quality and price is very reasonable. Highly recommended and will return again.

I now use only OurPCB because of their simple instant online quotation and ordering system with PCB drag and drop files. The PCB quality is excellent, with excellent competitive prices to meet my PCB delivery urgency as required. Mark provides quick, excellent & friendly technical support. I recommend OurPCB to all Aussie manufacturers to support our last Aussie PCB company!

Been working with these guys for over 10 years now. The quality of their PCBs is first class with excellent delivery schedules. Any problems or 'extras' are handled promptly and efficiently. No hesitation in recommending them for any PCB manufacturing.

OurPCB have supplied our company with PCB circuit boards for the last five years. Firstly the quality is exceptional - Mark makes ordering circuit-boards easy. Where as in the past we have done the run around with component supply many times - Mark makes the process decisive and simple. The service is top notch. Highly recommended.

I push these guys on every front from superfine technology through to quick delivery - the quality and service is the best I've had anywhere. A truly great fab shop that is a pleasure to work with.