Rigid-Flex PCB Manufacturer - Flex Rigid PCB Supplier

Get a free quote today and order your rigid-flex PCBs with confidence. Let’s make your project a reality!

5 Star Rating on

5 Star Rating on

Trusted by These Brands

- 1Order and Procurement

- 2PCB Manufacturing and Preparation

- 3Assembly and Soldering

- 4Inspection and Quality Control

- 5Finalization and Shipping

- Bare PCB in 8 working hours

- PCBA with components in 2 working days

- Bare PCB manufacturing

- Components sourcing

- PCB assembling

- Wire harness manufacturing

- Casing /Housing manufacturing

- Programming/Testing

Adrian Leitch

Andrew Durrant

Andrew Peeler

Andrew Wood

Ben Thomas

Darren Larosa

Debra Beukes

Eastern Europe Archives

frankyc

Fred Van

Greg MacDonald

John Powell

Jonathan Pippard

Jordan Thurgood

Justin Regan

Mark A

Mark Pagura

Maryanne Hassell

Matthew O'Neill

mitch clark

Oli

Peter Lambert

Sasha Marks

Slavko Mali

SPI MX

Steve Visser

Steven Munari

Steven Vatev

Tane Pendragon

Tasmiah Khan

Trevor Gardner

Free Consultation

Need rigid-flex PCBs?

We at OurPCB are here to assist you with your rigid-flex PCB needs. As a leading circuit board manufacturer with lots of happy customers all around the world, especially in the USA, we offer top-notch PCB assembly, including the design and production of rigid-flex PCBs. Our team of experienced professionals is dedicated to providing high-quality, reliable solutions to meet all your electronic needs.

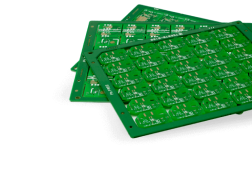

What are Rigid-Flex PCBs?

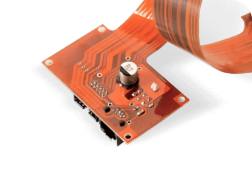

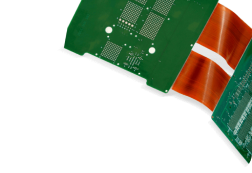

Rigid-flex PCBs are a hybrid circuit board combining components of rigid and flexible PCBs, and are used to connect electronic components in a variety of both consumer and non-consumer devices. This board type can be folded or flexed continuously on the flexible section, which usually joins two rigid parts.

What is the Cost of Rigid-flex PCB?

The cost of rigid-flex PCBs varies widely depending on the complexity and number of layers. Here is a detailed cost comparison based on complexity and layers:

- Rigid-Flex PCB (4-Layer):

- Low Complexity: $20 – $50

- Medium Complexity: $50 – $200

- High Complexity: $200 – $1,000+

- Rigid-Flex PCB (6-Layer):

- Low Complexity: $50 – $100

- Medium Complexity: $100 – $500

- High Complexity: $500 – $2,000+

These prices are influenced by factors such as the number of layers, the complexity of the design, the materials used, and the specific manufacturing processes required. For example, military and aerospace applications often use more advanced materials and designs, which can increase costs significantly.

Rigid-flex PCBs are generally more expensive than standard rigid or flexible PCBs due to their complex manufacturing process, which involves combining rigid and flexible materials to create a single integrated board. This integration helps in reducing the overall size and weight of the device while improving reliability and performance in demanding environments.

For precise pricing tailored to your specific project requirements, please request a free quote by filling out our form.

Flex PCBs vs. Rigid-Flex PCBs

Flexible PCBs have a bendable core material that can withstand vibrations and folding, and are made using an overlay process to protect the bendable annealed copper circuits.

Rigid-flex PCBs have both rigid and flexible PCB sections with the respective substrates and materials. The circuits in the rigid part can be inflexible etched or electro-deposited copper.

What are the Advantages of Rigid-Flex PCBs?

Enhanced Durability

The flexible part of the circuit is vibration-and shock-resistant, meaning it can hold heavier components without cracking. These boards are also more resistant to high temperatures, radiation, and other harsh environments, making them suitable for rugged applications.

Space and Weight Reduction

Rigid-flex PCB designs are more challenging to create because you have to use a 3D development space to have better spatial efficiency. But the result is a lightweight and space-optimized design that fits in compact electronics like wearables.

Improved Reliability

Compared to regular PCBs, the rigid-flex type has fewer connectors and interfacing materials. Interconnections are potential sources of failure, so this design makes the PCBs more reliable.

Rigid-Flex PCB Cost Efficiency in Production

Manufacturing rigid-flex PCBs is more expensive than building their rigid counterparts, but the cost savings come during PCB assembly. Since they replace wired interconnects (harnesses and connectors) with conductive copper layers inside the board, the assembly costs and error risks are lower.

Rigid-Flex PCB Design Freedom

The ability of rigid-flex circuits to adopt complex shapes and compact sizes gives you the freedom to experiment with different device designs because the PCB will fit inside more easily.

Reduced Assembly Time and Costs

With fewer interconnections and parts, assembling rigid-flex PCBs takes less time, minimizes wiring errors, and reduces costs because you won’t need manual labor to insert the connector wiring joints.

Our Rigid-Flex PCB Manufacturing Capabilities

Multiple Layers

We can build 2 to 30-layer rigid-flex circuit boards with a lead time of up to 2 weeks. The solder mask and silkscreen color are the same as those in regular rigid PCBs, and the surface finish will vary depending on your requirements.

High Quality Rigid-Flex PCB Material

We build these PCBs using industry-standard materials like polyimide, Rogers, and FR4. FR4 is the most popular material for building rigid boards, while polyimide makes high-quality flexible circuits. Rogers is a premium material that’s ideal for high-frequency circuit boards.

Expert-Level Precision

All PCBs must have precise circuit wiring, so we use state-of-the-art equipment to ensure the traces have tight tolerances and controlled impedances to match the specific application. We have the expertise to build all kinds of PCBs, and precision is our forte.

SMT and THT Components

The assembly lines in our factories in Shijiazhuang and Shenzhen have the equipment to mount SMT and THT devices, including in a mixed assembly, in the rigid-flex PCB. The SMT components include chips with packages like BGA, QFN, SOP, leaded, and leadless carriers.

Advanced Features

It’s challenging to manufacture advanced features like buried vias into rigid-flex PCBs, but we can do that, as well as include microvias and high-density components, especially on the rigid part.

Our Shijiazhuang factory can also handle IPC 6012 Class 3/A assembly, which is crucial when making sophisticated rigid-flex PCBs for military, medical, or aerospace applications.

Quality Control

Quality control is a significant aspect of the rigid-flex PCB production process. It includes methods like ICT, FPT, AOI, automated X-ray, solderability, and burn-in testing.

PCB Customization Options

Your requirements dictate what we can build. The variables at your disposal include the layer count (provided it’s below 30), materials (FR4, Polyimide, Rogers, Aluminum), and configurations like dimensions, thickness, and surface finish. We can laminate the board or leave it unlaminated if you prefer.

Industries We Serve

- Medical Industry: Devices like handheld monitors, wireless controllers, imaging equipment, cochlear implants, and pacemakers.

- Military Equipment: Weapon guidance systems, tracking and surveillance systems, communication systems, etc.

- Aerospace Industry: Radio communication equipment, radar devices, noise and vibration testing systems, control tower equipment, and sensors.

- Automotive Industry: Dashboard displays, transmission controls, AC systems, electronics control modules, and music systems.

- Telecommunications: Communication satellites, servers, routers, handheld units, signal processing systems, and base stations.

- Consumer Appliances: Wearables, TV remote controls, washing machines, ovens, solar power controllers, and electric irons.

- Manufacturing Industry: Control panels, electrical switches, CCTV surveillance systems, test equipment, and industrial ACs.

Global Services OurPCB Provides

Rigid-Flex PCB Design Consultation

Although we usually provide OEM services, we can ODM your rigid-flex PCBs because our engineers and technicians have the expertise to help you in the design phase.

This ODM service helps streamline the product early on for manufacturability, assembly, and testing to match our fabrication and assembly capabilities, which lowers the overall PCB cost.

Rigid-Flex PCB Prototyping

We have a dedicated PCB prototyping facility that provides full turnkey production with a fast turnaround assembly of 5 days for 1 to 2 layers and 11 days for 12-layer boards (excluding shipping). The maximum prototyping layer count is 32 layers.

PCB Production

Whether you want low-volume assembly (as low as 250 pieces) or high-volume assembly (above 1,000 PCBs), we’ve got you covered.

We also provide turnkey services, so we can do the manufacturing and assembly under one roof for small or large-batch orders.

Testing and Inspection

During fabrication and assembly, we always include several testing steps to check the board’s functionality and integrity. Some of these steps include ICT, solderability, impedance, hole resistance, and thermal shock testing.

Shipping and Delivery

During a product’s production life cycle, we have two shipping and delivery steps. The first comes after prototyping. We can send a few test boards via DHL, EMS, TNT, or FedEx.

We provide these same options for final product delivery, so you can compare costs and shipping times to pick the most suitable carrier.

After-Sales Support

Our services don’t stop once you get your delivery. Our technical team is available at your disposal to provide technical support should the PCB malfunction.

We keep the necessary documents for follow-ups to identify the cause of the issue, then fix them at no extra cost if they’re manufacturer-related. If it’s a component issue, we buy these parts with warranties, so we can also replace them at no extra charge.

Why Choose Us as your Rigid-Flex PCB Assembly Manufacturer?

Decades of Expertise

With almost 20 years of experience in providing end-to-end PCB solutions and a clientele list that includes Intel and ABB, we’ve consistently proven our abilities and expertise in PCB production over time.Unwavering Commitment to Quality

Quality is at the forefront of our assembly manufacturing process. Our assembly plants are ISO 9001 certified, and our internal processes meet various industry standards, such as RoHS, UL, and CE.Cutting-Edge Facilities

Both our assembly plants feature state-of-the-art Siemens and Yamaha SMT lines that enhance our production capabilities by ensuring precise and efficient assembly.Customer Satisfaction

Our customers aren’t shy to share their satisfaction. Some of the big names we’ve worked with are Intel, ABB, and Sigfox. We’ve gotten positive reviews and feedback from them and all other customers over the years, which is a testament to our professional work in the PCB industry.Advanced Technology

Our advanced manufacturing and assembly lines enable us to build and assemble rigid-flex PCBs with high precision while adhering to factors like tolerances and minimal interference.Environmental Responsibility

As the world of electronics becomes more eco-friendly, we’re making manufacturing/assembly changes. Our processes stick to eco-friendly standards like RoHS, which prevent the use of toxic materials, such as lead, on solder.Versatility in Production

We can develop prototypes, small batches, or high-volume PCB orders at either quick or regular turnarounds, and the boards can have different specifications (number of layers, materials, etc.). No matter your order, we don’t compromise on quality and efficiency. Get in touch today by submitting your design documents to get an online quote from our experts. Or request consultation services, which will help refine the requirements to begin the ODM process.Services Related to Rigid-flex PCB Manufacturing

- PCB Assembly Services: Comprehensive solutions for assembling printed circuit boards.

- Quick Turn PCB Assembly: Fast and efficient PCB assembly to meet tight deadlines.

- High Volume PCB Assembly: Scalable solutions for large-scale PCB production.

- Flexible PCB Manufacturing: Specialized in manufacturing flexible PCBs for diverse applications.

- Low Volume PCB Assembly: Cost-effective solutions for small batch PCB assembly.

- Turnkey PCB Assembly: End-to-end services covering all aspects of PCB production.

- PCB Design Services: Expert design services to bring your PCB concepts to life.

- Rigid-Flex PCB Manufacturing: Manufacturing robust and versatile rigid-flex PCBs.

- PCB Prototype: Rapid prototyping services to test and refine your PCB designs.

- Rogers PCB: High-frequency PCBs ideal for RF and microwave applications.

- Aluminum PCB: PCBs with excellent heat dissipation properties, perfect for high-power devices.

- Metal Core PCB: Thermal PCBs with metal bases for effective heat management.

- High Tg PCB: High glass transition temperature PCBs for improved thermal performance.

- High Frequency PCB: Designed for high-speed and high-frequency applications, ensuring superior signal integrity.

- Heavy Copper PCB: Built with thicker copper layers for high current and enhanced thermal management.

- HDI PCB: High Density Interconnect PCBs offering advanced circuitry in a compact design for complex applications.

- Custom Cable Assembly: We offer a wide range of customized cable services, hybrid cables, and wire harnesses.

- Turnkey PCB Assembly: Our comprehensive solutions cover everything from design to production and testing, ensuring quality and efficiency while saving you time and cost

Rigid-Flex CASE STUDY

Back to top: Rigid-Flex PCB

Customer Reviews - Rigid-flex PCB Manufacturing

- Author: Amelia Price

Item: Rigid-Flex PCB

Review: The rigid-flex PCB from OurPCB exceeded our expectations in both quality and performance. Its durability and reliability are remarkable. - Author: Lucas Brooks

Item: Rigid-Flex PCB

Review: We have been using OurPCB's rigid-flex PCBs for our medical devices, and they have proven to be highly effective and efficient. - Author: Emily Howard

Item: Rigid-Flex PCB

Review: The combination of rigid and flexible parts in these PCBs provides great design flexibility. Highly recommended. - Author: Mason Lewis

Item: Rigid-Flex PCB

Review: OurPCB's rigid-flex PCBs are cost-effective and offer excellent performance in high-stress environments. A great choice for complex applications.

Rigid-Flex PCB Manufacturing Service FAQs

What is the Difference Between Rigid-Flex PCBs and Standard PCBs?

Standard PCBs are rigid, but rigid-flex PCBs combine rigid and flexible PCB properties into a single, lightweight, space-saving structure. The flexible board is also less susceptible to mechanical stress because it can absorb vibrations.

Can you Manufacture Rigid-Flex PCBs with Blind and Buried Vias?

Yes. However, making these vias requires a different set of design rules because of the materials used and the manufacturing process.

Can you customize Rigid-Flex PCBs to Fit Specific Design Requirements?

The flexible component of the Rigid-Flex PCBs can be bent, shaped, wrapped, or folded into any 2D or 3D shape. These features make Rigid-Flex PCBs perfect for use in medical and surgical equipment, consumer electronics, automotive and space applications, and smart wearable devices, that needs both properties of durable rigid boards and the flexibility of flexible circuit boards.

Is it Possible to Order Small Quantities for Rigid-Flex PCB Prototype Development?

Yes. Our lead time for 1 to 2 layer prototypes is 5 days, which stretches up to 11 days for 12-layer PCBs (shipping time not included). Overall, we can prototype 1 to 32-layer PCBs within 2 weeks, and we’ll give you a formal quotation within 8 working hours after receiving your request.