Do you want your PCB sourcing to be successful?

In that case, you have many components to consider.

This guide will show you the standards for choosing PCB suppliers, why you select PCB from China, and more about PCB services to make the right choice for a PCB manufacturer.

Contents

- 1. PCB manufacturer--The Standards for Choosing PCB Manufacturers

- 1.1 PCB manufacturer--What are the requirements for your product?

- 1.2 PCB manufacturer--Manufacturer requirements:

- 1.3 PCB manufacturer--Specific PCB issues you should know:

- 2. Why Choose China PCB?

- 2.1 Benefits and features of China PCBs

- 2.2 How to choose a China PCB manufacturer?

- 3. More About PCB Service:

- 3.1 Cheap PCB prototypes

- 3.2 11 PCB manufacturer--Choices for PCB fabrication and assembly

- 4. PCB manufacturer--Conclusion

Special Offer: Get $100 off your order!

Please email [email protected] for details.

1. PCB manufacturer--The Standards for Choosing PCB Manufacturers

Before choosing a PCB manufacturer, consider your electronic device's requirements.

You also need to consider the requirements of a manufacturer.

There are more complex PCB issues to which you should pay attention.

The following is a list of 3 points to always have in mind when scouting your PCB manufacturer.

1.1 PCB manufacturer--What are the requirements for your product?

If you can determine your product's requirements, you'll be able to narrow down your choices of PCB manufacturers.

Four of these questions will be covered here, and they will relate to the requirements of your product as much as possible.

1.1.1 PCB manufacturer--What is the market for your product?

Do you determine the market for your products?

The situation differs from selling your products to North America, Europe, Asia, or other needs.

It is vital to position your product.

Deciding whether your product is low-end, standard, or premium would be best.

Then you will select the Manufacturer that has advanced or ordinary equipment accordingly.

Do you know the specific application of your products?

Are the outcomes for automation control, instruments, communication, automobile, medical care, military defense, or others?

1.1.2 pcb manufacturer--Determine your budget

The budget will directly affect the materials that you want to use.

It would be best to consider using premium or ordinary materials according to your budget.

Your budget also affects your production level.

Your account depends on whether to produce new products or cut back on production.

1.1.3 pcb manufacturer--Choosing materials

Do you know what kind of materials is best for your device?

First, decide whether your product is low-end, standard, or premium.

Then you may choose the materials accordingly.

Additionally, the level of flexibility will also determine your PCB sourcing expectations.

Your product might require a specific design of the printed circuit board.

For example, wearable consumer electronics like smartphones might need flexible or flex-rigid PCBs.

Please note that you can also choose between standard and HDI PCBs.

The latter uses high-density interconnect technology, which allows them to place extra components while maintaining minimal size and weight.

1.1.4 PCB manufacturer--Production time

This question concerns whether you want your idea to make money and the urgency to sell your invention to the public.

The turnaround time, the more money the Manufacturer will expect from sales.

Every company cares about every invested cent. It is vital to stay on schedule by releasing new products and services.

That is why you can't afford any item to take longer delivery than predicted, including printed circuit boards.

1.2 PCB manufacturer--Manufacturer requirements:

Aside from having specific requirements for your products and looking for manufacturers with similar conditions, it would help if you also had some other questions in mind when choosing a manufacturer.

Including the Manufacturer's experience, production capacity, established track record, having a professional staff ready to help, testing procedure, and assisting you with marketing.

1.2.1 Does the Manufacturer has experience in producing devices similar to yours?

The experience can be crucial because the chances are that they have already done a similar project to the one you are asking for.

That way, you can ensure that someone knowledgeable and skillful will handle the PCB assembly and that your board is high-performing and reliable.

1.2.2 What kind of production capacity is possible with this Manufacturer?

It would be best to decide on a company based on your budget and product requirements.

Ensure the provider has the manufacturing capabilities required to design your board.

That includes appropriate equipment that can create the type of PCB you want.

Additionally, you want to confirm that they use the materials you would like in the PCB designed for your application.

Ultimately, the company needs to be ready to meet your expectations regarding the cost and delivery of the boards.

1.2.3 Does the Manufacturer have an established track record?

The issues surrounding this question are twofold.

First, you can select a manufacturer with an established track record to ensure they will produce your electronic device correctly.

The other issue involves taking a risk.

While taking a chance on a manufacturer that is not very experienced, in this way, both you and the manufacturing firm can gain notoriety simultaneously.

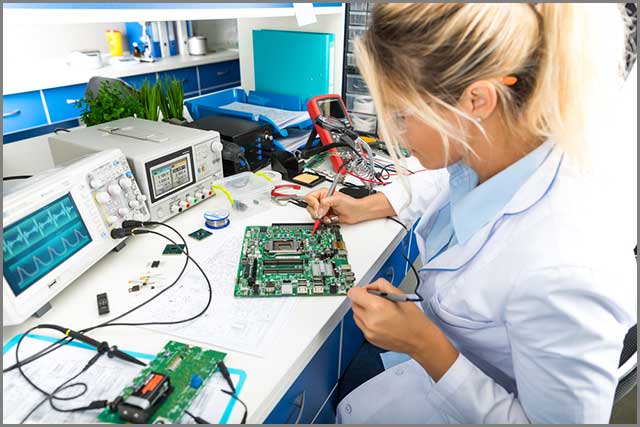

1.2.4 Do They Have a Professional Staff Ready to Help?

The company needs to have the right combo of equipment and staff. Modern machines and tools are not worth much if no one can use them properly.

That is why you should look for a manufacturer that gathers a team of trained and experienced engineers.

Professional staff will be there with you every step of the way.

They understand the need to clarify your dilemmas and answer any questions you might have relating to your product.

That is particularly important if it is your first time working with that provider.

Pay special attention to the behavior of the staff.

1.2.5 PCB manufacturer--What is the Manufacturer's testing procedure?

PCB manufacturers are responsible for a lot of things regarding electronics.

If your target market for your inventions is large enough, it will be necessary for testing to be very prioritized.

It is especially true if your device is for something specific.

Knowing the Manufacturer's testing procedure and all of the details of the testing procedures will also give you peace of mind.

It is never a good thing to represent a device that has not been tested thoroughly.

1.2.6 Will the Manufacturer assist you with marketing?

Marketing can be a very tedious task.

When done independently, it can take months or even years to develop effective marketing strategies for any product.

Electronics are not exempt from this, and if you are a designer who does not have a marketing team or does not have the capital to spend on marketing, you will want all the help you can get.

You will probably want your Manufacturer to assist you with marketing.

1.3 PCB manufacturer--Specific PCB issues you should know:

Aside from knowing the requirements of your product, and manufacturer requirements, there is something more you should pay attention to the PCB issues.

The following is a list of 8 points for your information.

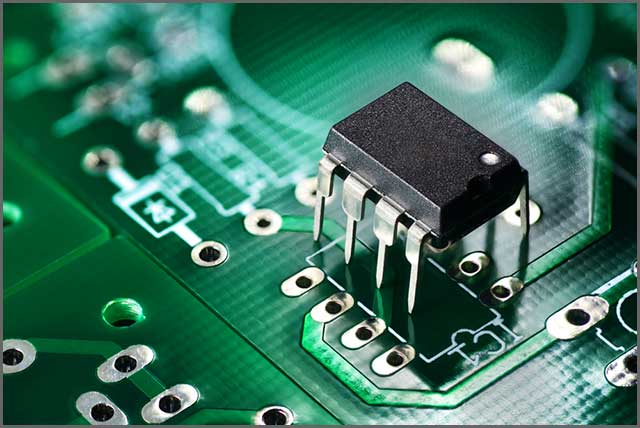

1.3.1 PCB manufacturer--PCB geometry and circuit

As humans continue shrinking the electronics in daily life, the requirement for concise documentation continues to grow, becoming more critical at every node.

The dimensions provided are the determinants of either failure or success. If the tolerances are very tight, the costs will be high.

Conversely, loose tolerances bring about misfit parts that may need some reworking.

To avoid short circuits and other challenges that may arise during printed circuit board operation, there's a need to pay attention to such a problem.

1.3.2 PCB manufacturer--Copper wire area

Copper is a common material used in making traces in circuit board manufacturing.

Hints are essential elements because they transmit electrical signals to different parts of a printed circuit board.

Without such traces at their intended place, printed circuit boards will not be functional as intended.

The most significant benefit of using copper material is it's significantly conductive, meaning that it can transfer signals without losing electricity in the process.

Additionally, you'll only need small tons of copper to complete your project instead of using a lot of it.

1.3.3 pcb manufacturer--Handle solder carefully

You'll have to handle the welding carefully to ensure that your PCB board manufacturing comes out as planned.

The soldier is an alloy of metal that's melted to create a permanent bond between electrical components.

Poor handling of the weld may bring about disturbed, cold, or overheated joints.

1.3.4 PCB manufacturing selection of solder mask

A solder mask, also known as solder resist, is a thin layer that covers copper traces of a printed circuit board to protect the metal elements from oxidation, dirt, and corrosion.

Additionally, solder masks aim at preventing soldering bridges from taking place on the covered areas of a printed circuit board.

If you don't have solder masks on PCBs, the copper traces connected with solder paste may bring about short circuits.

Deciding on the appropriate solder mask to use largely depends on the board's dimensions, components, holes, surface layout, conductors, and the final application of where the product will be applied.

Dry masks work best if the board surface is flat. On the other hand, liquid options are ideal for PCBs with sophisticated surfaces.

1.3.5 PCB manufacturing signal and rf issues

Signal integrity is one of the biggest problems manufacturing high-speed printed circuit boards, especially in custom electronics manufacturing.

To ensure that you reduce potential problems related to signal integrity, a printed circuit supplier needs to provide PCBs with durable designs.

Apart from signal integrity, printed circuit board designers or RF have to employ laminate materials ideal for the current project.

The basis of your choice has to meet or satisfy the electrical needs required by the RF circuit, such as signal speeds and loss rate, among others.

1.3.6 PCB manufacturing through-hole type

Through-holes are copper cylinders placed or formed in holes drilled on a printed circuit board.

Through-holes are purposeful in electronically and thermally joining traces, pads, and polygons on several printed circuit board layers.

The critical thing to note is that the type of vias depends mainly on the drawings used on the circuit board.

For instance, it may be ideal to use through via for a simple two-layer board.

But if you are manufacturing boards with more than two layers, you may find it perfect to use buried or blind vias, though at some increased costs.

1.3.7 PCB manufacturing thermal issues

We are lately witnessing an increasing demand for highly power-hungry devices.

For this reason, trying to avoid thermal problems with products is now more critical than before.

Problems may arise, especially in three different areas of thermal relief, solder parts, and thermal stress.

Luckily, designers can use specific printed circuit board thermal design procedures to mitigate or handle these potential problem areas.

Having the right or ideal thermal management practices or techniques will help keep your board as fresh as possible as you design your next revolutionary products.

1.3.8 The importance of testing

Printed circuit boards find substantial use in almost all electronic devices and are responsible for the functionality of the electronic device.

However, defects during production may see a manufacturer releasing boards that won't meet the market's demands.

It is the reason why testing is essential.

Testing catches errors and faults too early before undertaking the final production run.

With testing, designers can detect and rectify problems before releasing their products.

Screening saves PCB manufacturers a lot of time and costs.

Special Offer: Get $100 off your order!

Please email [email protected] for details.

2. Why Choose China PCB?

International companies and product developers are widely concerned about China's huge PCB market for its high quality and low price.

In this part, we'll walk you through choosing the right China PCB manufacturer that provides excellent products and value-added service.

2.1 Benefits and features of China PCBs

Regarding a customer's requirements, China PCBs possess the right criteria to fulfill their need.

2.1.1 Save cost

When buying PCB online in China, you can tag printed circuit boards and other accessories illustrated on their websites.

The key goal is to ensure you receive all your orders simultaneously, saving you from time wastage and spending more money with individual requests.

2.1.2 Inventory

If customers sourced PCBs from their own country, they would have to pay large sums for inventory and warehouse costs.

Comparatively, outsourcing PCB manufacturing services in China eliminates the cost of keeping excess inventory.

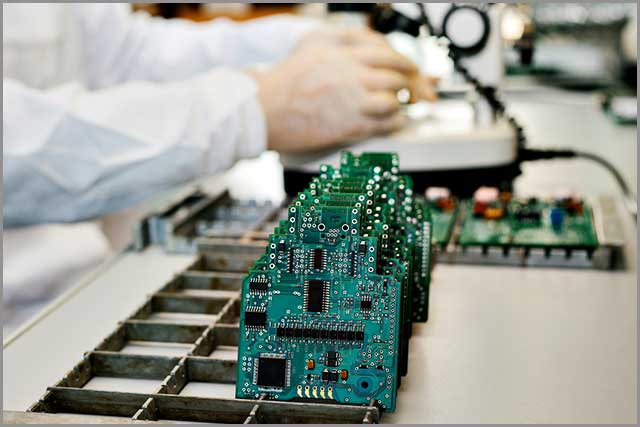

2.1.3 Production speed and quality

China's PCB manufacturers have the latest equipment to develop advanced high-speed models.

It is due to their impressive rate of production and immense labor force.

China's companies can make accurate duplicates of electronic components from other countries at a reduced cost of materials and labor.

Therefore, customers won't be compromising on quality either.

2.1.4 Technology, capability, and experienced experts

China's PCB manufacturers have advanced technology to make complex and innovative circuit boards, while the workforce includes competent engineers and assembly teams.

With so much of the world's PCB production channeled to the country, the workforce there is skilled at assembling accurate PCBs and effectively fulfilling its requirements for design.

2.1.5 Environmental policy

China's government put one of the strictest environmental protection policies(See the link below) into effect in recent years.

The manufacturers are trying their best to ensure their processing systems and the sources of their raw materials won't harm the environment.

Then Consumers will get guilt-free purchases, and the products they use are environment-friendly.

2.1.6 Production standardization

China's PCB industry has set standards for producing modern and in-demand PCBs.

Product standardization across manufacturers and companies makes it easy for customers to compare suppliers and their products.

2.1.7 Stable delivery time

As a PCB supplier or distributor, the amount of time a production company spends delivering your product is essential.

However, China remains the best option regarding short delivery times.

Once you have requested, your order will be processed and shipped quickly.

Also, the platforms allow you to contact them directly, unlike other manufacturers from other parts of the world.

2.1.8 Payment terms

With clients from all over the world, China has devised the best payment options.

Most production companies accept payment options like PayPal, credit/debit cards, direct bank transfers, and e-wallets.

2.2 How to choose a China PCB manufacturer?

Regarding China PCBs, there's an endless number of manufacturers to choose from.

To help you get high-quality and low-cost PCBs, we've compiled which crucial steps you should take to select a reliable China PCB manufacturer.

2.2.1 Analyze their sample

The customer must request PCB samples to evaluate whether a manufacturer's product meets the need.

If the customer has adequate knowledge about PCBs, they can quickly evaluate the Manufacturer's innovative capacity and production potential by analyzing the quality of the provided samples.

If they meet your standard, you'll determine whether they have the necessary resources and technology to achieve higher demands for customized PCBs.

2.2.2 Test their voice on customer feedback

Customer service and feedback responses can significantly affect your experience with a China PCB manufacturer.

Customers who have had an unpleasant experience with China PCB manufacturers complain that suppliers lack adequate communication skills and cause costs to rise.

Therefore, learn how quickly and appropriately a manufacturer addresses and responds to customer feedback.

After that, you can make the final decision as to whether you want to employ their services or not.

2.2.3 Do they possess international certification?

The main clients of China's PCB products are from overseas.

Every accredited production company has an inspection certificate that helps you decide whether they are registered to sell their products.

On the websites, you will access international certification documents that portray their competence, compliance standards, and approval from third-party entities.

2.2.4 While you're at it, you should also determine if the company complies with the environmental protection regulations

You should ensure that the Manufacturer complies with China's new environmental protection regulations.

Ensuring this aspect in the early stages of selecting a China PCB manufacturer can prevent any disruptions later, which can occur if a manufacturer isn't compliant with production codes.

2.2.5 Quality of pre-sales and post-sales services

Customers should check a company's pre and post-sales services to determine whether they want to outsource the Manufacturer.

In the pre-sales process, observe how long it takes them to address your queries and offer detailed enough information.

In the post-sales process, check their tech support, warranty, and package return services. If you find that they respond promptly, this is beneficial because it means added value in quick pre-sales and after-sales service.

2.2.6 Capability and equipment

If possible, customers should always try to access at least the manufacturing location of the PCB.

A company's production equipment and manufacturing capabilities are dedicated to impeccable service and efficiency.

2.2.7 Lead time and delivery

Even though different PCB types have different delivery schedules, check if production can be completed and delivered within the set period.

If yes, it's a sign of substantial production capacity, and you can rely on them to perform the agreed products on time.

3. More About PCB Service:

Here is more information about PCB service, including cheap PCB prototypes, manufacturing, and assembly manufacturing.

3.1 Cheap PCB prototypes

It can be advantageous for any appliance engineering, designing, or manufacturing firm to explore cheap PCB prototyping.

But how do we choose a competitive PCB prototype supplier? What factors should be considered in this?

Let us help you answer them one by one.

3.1.1 Benefits of using cheap PCB prototypes

Since you are only ordering a blank template, using an inexpensive PCB prototype for nearly any device is possible without sacrificing anything.

Here are some other benefits of using cost-effective PCB prototypes.

3.1.1.1 PCB manufacturer--Low risk and low loss

Low cost also means low risk. Design problems can arise after testing.

If you used a cheap PCB prototype to design your PCB, losses are minimal, reducing the risk you take.

And Cheap PCB prototypes also have the same quality despite their straight appearance.

3.1.1.2 pcb manufacturer--Faster production

Prototype PCBs can be manufactured quickly.

The average order of a prototype PCB is two or so days, making it easier to start testing processes.

It can be a godsend when it comes to time-sensitive projects. In just a matter of weeks, you'll be able to produce PCBs for whatever device they are needed for when you order prototype PCBs.

It can take much longer when using PCBs that require production when requested.

3.1.1.3 PCB manufacturer--Ability to detect flaws earlier

The main risk of ordering the production and assembly of the PCB is that it takes a lot of time and money to start the repair process.

While detecting and repairing flaws is a normal part of testing PCBs that a manufacturer has ordered, doing this is much easier when using a cheap PCB prototype.

It is because flaws in a prototype PCB are easy to detect and can usually be seen earlier. It can save a lot of time and money.

3.1.1.4 PCB manufacturer--Solutions from one source, not multiple sources

PCBs that aren't ordered from their prototype suffer some drawbacks that go unnoticed.

PCBs are not ordered straight from the prototype and are often collected from multiple production chains.

If something goes awry, you'll need to seek different solutions from different sources.

It can cost a lot of time and possibly money, resulting in projects being held up.

3.1.2 PCB manufacturer--Things to consider when ordering or purchasing cheap PCB prototypes

Quality is always an issue when dealing with anything that entails PCBs, but this is even more true for PCB prototypes.

Regarding quality, it will make sense to look for how customizable the board is since you are essentially ordering a "blank template" of a PCB for a prototype.

3.2 11 PCB manufacturer--Choices for PCB fabrication and assembly

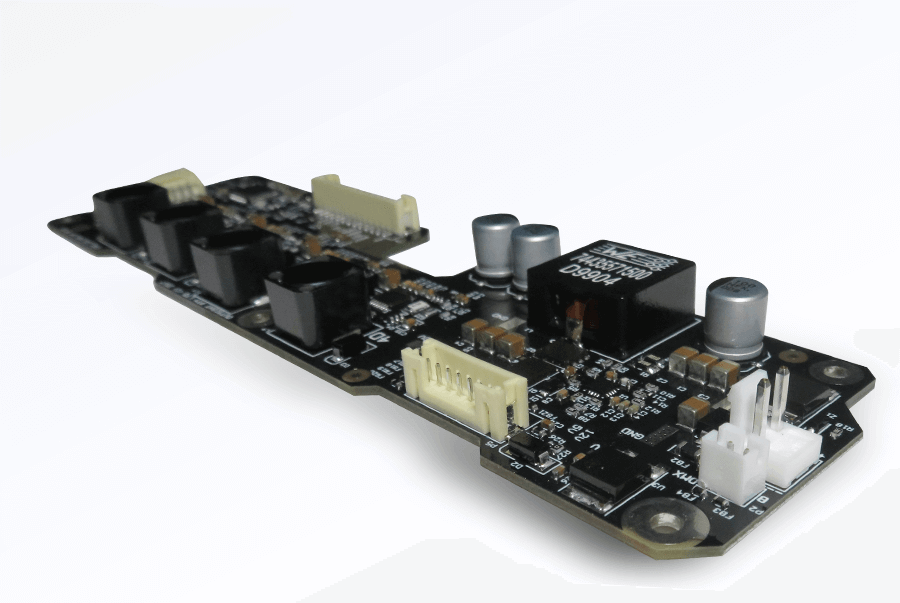

In short, a PCB tells electricity where to head, an aspect that brings your electronics to life.

What is the production process for these devices? What is the right method for PCB manufacturing and assembly?

This article is a helpful guide aimed at helping you in choosing the best method for PCB fabrication and assembly.

3.2.1 PCB manufacturer--PCB manufacturing and assembly-etching

We describe etching as a subtractive method that PCB designers use when producing printed circuit boards.

There are several solutions that designers can use to etch PCBs.

However, some of the basic ones are Ferric Chloride and Ammonium Persulphate.

Ferric Chloride is ideal for hobbyists and students, while Ammonium Persulphate is better suitable for established PCB designers.

Ammonium Persulphate is expensive but hard to control, a reason why hobbyists may find it challenging to use.

3.2.2 pcb manufacturer--Direct manual operation

On most occasions, manual welding is perfect for low-volume work and prototypes.

Of importance to note, though, is that while a direct manual operation is one of the quickest ways of getting patterns on the board, it may be challenging to locate the traces accurately, especially when using IC packages during the design process.

3.2.3 PCB manufacturer--PCB manufacturing and assembly-photographic

You can use the photographic process to achieve an impeccable board during PCB manufacturing and assembly.

At this moment, you should cover the copper on the bare board with a thin lining of photo-resist.

You then expose it to light through a photographic film detailing all the relevant tracks that will now be on your new board.

Now we can copy the image, wherefrom their developers can easily use any PCB software to transfer it to the real circuit board.

Better yet, once a designer is done with the artwork film, the same artwork film can find use repeatedly when additional panels are needed.

PCB designers must employ a suitable graphics package/drawing or an ideal PCB CAD program for good artwork.

3.2.4 pcb manufacturer--Direct plating

Direct plating is a low-cost and environmentally friendly process compared to electrochemical plating.

Natural plate eliminates the use of heavy metals while helping PCB designers to reduce their operating costs.

A direct scale is another excellent and cheaper way of getting the best PCBA results.

3.2.5 PCB Manufacturer--Screen printing technology

Screen printing technology helps engineers and manufacturers identify all the board parts, with the ink mainly used as a non-conductive epoxy.

While the use of screen-printing technology seems to decline, the reason is that the technological demands of printed circuit board designs outweigh those of screen-print capabilities.

For example, photo imaging is more precise and accurate than screen printing.

3.2.6 PCB manufacturer--Selection of photographic tools

Selecting various photographic or imaging tools is also essential when manufacturing printed circuit boards.

PCB assembly is a long process that involves the following steps:

- DFM

- PCB fabrication

- Material inspection

- Solder paste printing

- Machine placement

- Reflow soldering

- X-ray inspection

- Wave soldering

- Manual soldering

- Final inspection

Proper photographic or imaging tools are necessary for the best PCB assembly and fabrication results.

The above steps call for using the right photographic tools suitable for the job.

Examples of specific tools include post-press equipment, milling machines, and paper-slitting cutting machines.

3.2.7 pcb manufacturer--PCB assembly methods

3.2.7.1 pcb manufacturer--SMT assembly technology

With electronics manufacturing gaining momentum, more efficient processes became necessary, bringing about SMT assembly technology.

SMT is one of the best PCB fabrication and assembly methods based on a host of advantages that come with it, such as the following:

- Simplicity

- Less prone to error

- Efficiency

- Affordability

3.2.7.2 PCB manufacturer--Manual PCB assembly technology

Even though SMT line machines bring about better results and in a consistent manner for most printed circuit boards, there are specific times when printed circuit board assembly by hand makes a lot of sense.

For instance, it would be ideal to do so manually when undertaking PCB fabrication and construction for prototype boards of low quantity.

Similarly, parts with unusual shapes may bring complications when handled by machines.

Again, manual assembly is suitable in such a case.

3.2.7.3 pcb manufacturer--Reflow soldering technology

The reflow soldering technology applies solder paste to temporarily attach thousands of small electrical parts to the intended contact pads.

After this, the whole assembly gets subjection to some controlled heat.

Reflow soldering is another excellent method for PCB fabrication and manufacture because it brings about reliable soldering and is easy to control and monitor.

It is highly ideal when it comes to the mass production of electronic components.

3.2.8 PCB manufacturer--PCB assembly equipment

The best way to carry out PCB fabrication and assembly is by employing the right printed circuit board equipment suitable for the job.

As a printed circuit board designer, using substandard tools or equipment not meant for the job might see you producing printed circuit boards that will not function as desired.

3.2.9 PCB manufacturer--Functional test selection

Printed circuit board's functional tests get done at the end of the production process to ensure that the manufactured products won't fail or experience a shortened shelf life.

The Selection of a test depends on what the designer wants to achieve.

Examples of functional tests include:

- X-ray inspection

- PCB solderability test

- Micro-sectioning analysis

- Solder float test

- PCB contamination test

- Peel test

4. PCB manufacturer--Conclusion

OurPCB is your perfect partner in the world of PCB sourcing.

The company has state-of-the-art equipment that complies with the latest standards.

We have years of experience in the PCB industry and a portfolio of simple and complex projects that we completed.

OurPCB is ready to offer affordable prices and the best ratio of cost and quality.

The company is experienced, reliable, and prepared to deliver worldwide in the shortest possible timeframe.

Special Offer: Get $100 off your order!

Please email [email protected] for details.