Menu

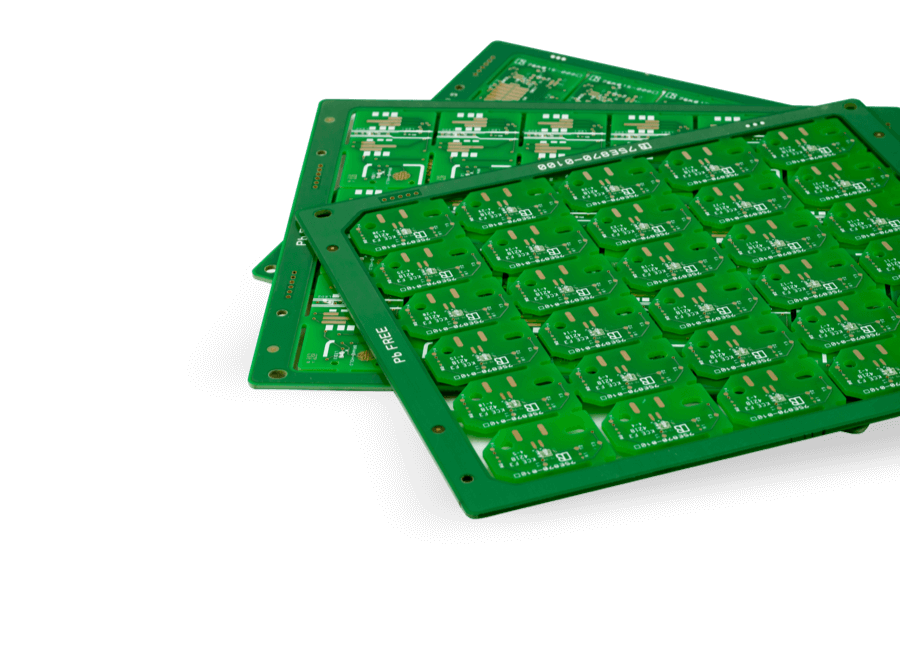

PCB Manufacturing is focusing on small to medium volume orders, Very competitive price for the volume from 1 -100 square meters for you.

And you can give OurPCB 4 kinds of files format (Gerber, .pcb, .pcbdoc or .cam file format) for your PCB Prototype Manufacturing.

To perform complete DRC checks of all Client files and inform you immediately if we find any problem.

We then will work with you to correct the files, so they are suitable for manufacturing.

Please check our capability overview below for reference.

Please contact us if you have a special requirement not listed in the following table.

We have our branch in Australia. If you are an Australian customer, you can click on this website.

Specification

PCB Capability

Layer Counts

1-32 layers

Lead Time

Normal: 5-6 Days

Expedited: 24-48Hours

Expedited: 24-48Hours

Materials

FR4, High TG FR4,Halogen Free material,CEM-3, Rogers HF material, etc.

Finished Copper Thickness

0.5-6 OZ

Finished Board Thickness

0.2-6.0mm

Min. Line/Track Width&Space

3mil

Qualifications

ISO14001:2015, ISO9001:2015, Certified

IATF16949: 2016,Certified

IATF16949: 2016,Certified

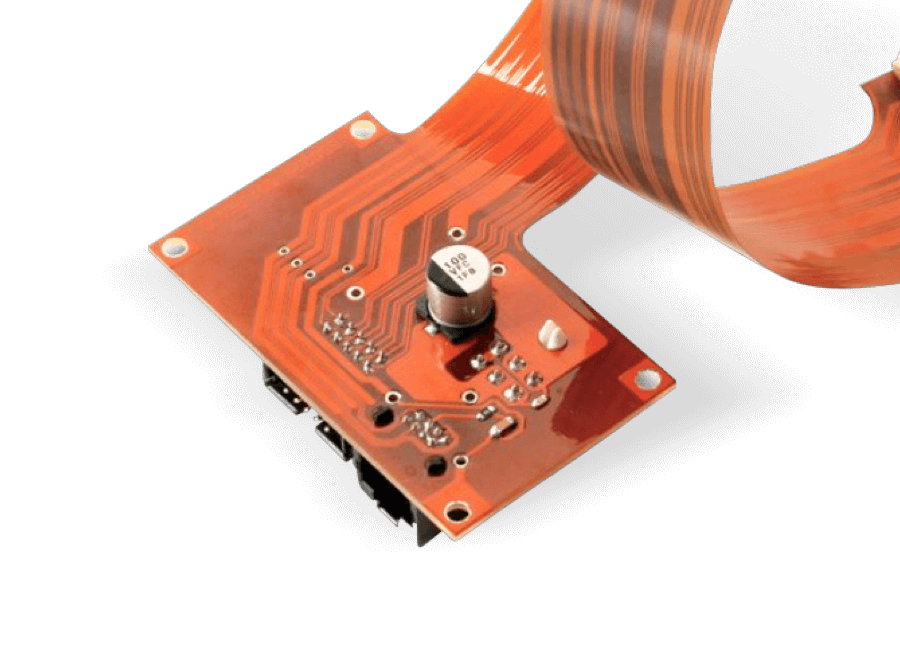

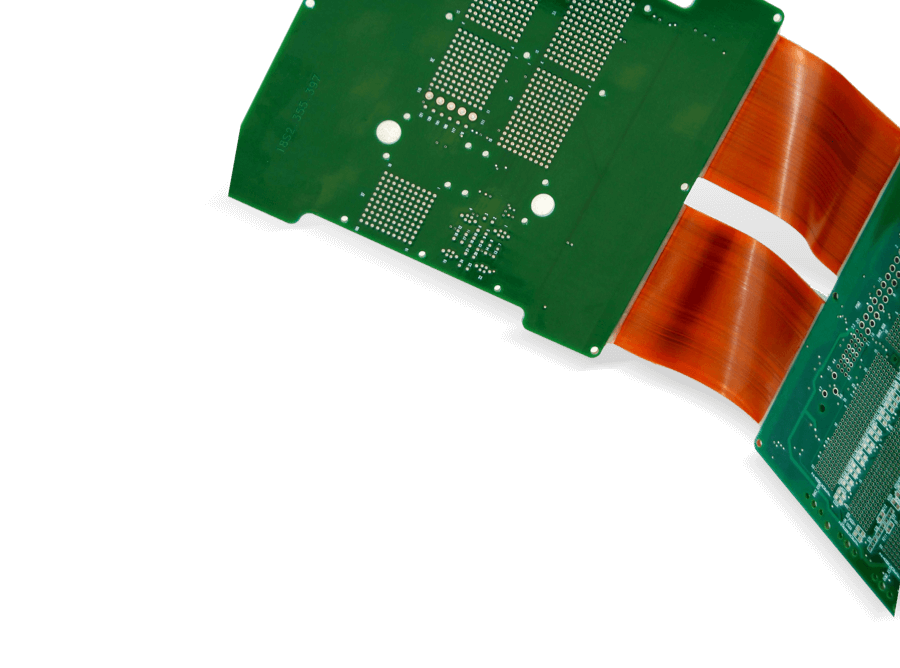

Technology

On-Across Blindried Vias, Characteristic Impedance Control, Rigid-flex Board etc.

Solder Mask Color

green, black, blue, white, red, yellow, and matt, etc.

Legend/Silkscreen Color

white, yellow, black, etc.

Surface Treatment

HAL, Lead Free HAL, Immersion gold, OSP, Immersion tin, Immersion silver, etc.

Wrap and Twist

≤0.7%

Other Technology

Gold finger, peelable mask, Non-across blind-buried vias, characteristic impedance

control, Rigid-flex board etc.

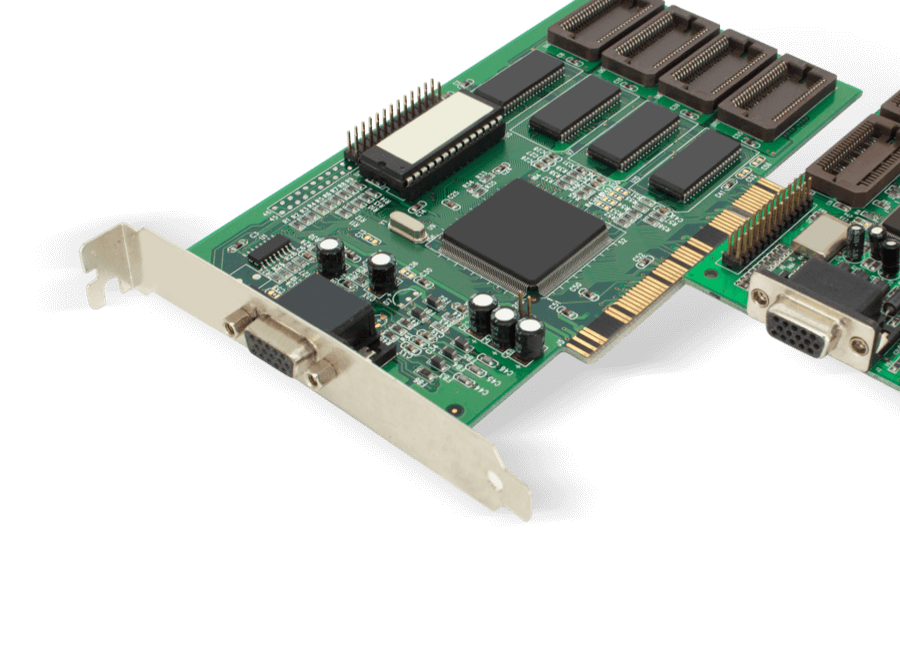

pcb board manufacturing CASE STUDY

12 Layers PCB

Black Solder Mask

CNC Routing

Gold Finish

Previous

Next