We have written about PCB building and fabrication, but PCB assembly as a topic is rarely touched. In this article, we'll talk about the steps to take to get cost-effective and high-quality output.

If you struggle to find the right assembler for your PCB or are afraid of the final output, then worry not. These tips will make your PCB assembly a success.

Contents

- 1、PCB Assembly--What is the Printed Circuit Board Assembly?

- 2、PCB Assembly--Pay Special Attention to File Formats

- 3、PCB Assembly--Get in Touch With Your PCB Assembly Provider

- 4、PCB Assembly--Offshore Providers May Be Good, But Not Always

- 5、PCB Assembly--Dododododododonot Count on a Single Supplier

- 6、PCB Assembly--Consider Naming and Labeling Parts

- 7、PCB Assembly--Don't Neglect the Design For Manufacturability Test

- 8、PCB Assembly--Recheck All Trade-offs

- 9、PCB Assembly--Testing Before You Order

- 10、PCB Assembly--Conclusion

Special Offer: Get $100 off your order!

Please email [email protected] for details.

1、PCB Assembly--What is the Printed Circuit Board Assembly?

Printed circuit board assembly, also known as PCBA, can be a complicated concept, mainly because it is not the same as printed circuit board manufacturing, also known as PCB.

These are two different disciplines with different sets of standards and requirements.

Printed circuit board manufacturing, as the name suggests, deals with the fabrication of the circuit board itself. On the other hand, the PCB assembly refers to assembling or placing components on the fabricated board.

Now without much ado, let's have a look at some PCB assembly tips:

These tips will ensure you get the desired results. The key lies in being careful and preparing in advance.

Image 1: PCB assembly

Image 1: PCB assembly

2、PCB Assembly--Pay Special Attention to File Formats

Choose a manufacturer who is experienced in dealing with the format that you plan to use. It is crucial because not all manufacturers may cater to all file formats.

Gerber and CAD are the two most popular options you have. Today's boards are very complex. Several layers of components, vias, and traces need to fit together to provide the required level of precision.

PCB file formats may not be the most exciting part of PCB design, but they are essential. Gerber is the most common and standard format. Hence a large number of assemblers offer it. On the other hand, CAD files are generated by CAD and other such software.

They follow the OBD++ standard, but you may also find some following the less popular IPC-2581 bar. Discuss these requirements with the assembler so that there are no problems later on.

3、PCB Assembly--Get in Touch With Your PCB Assembly Provider

It doesn't matter what kind of a working relationship you have with your PCB assembler; it is still essential to have a conversation before proceeding with the process.

We suggest that you communicate with your assembler at the design stage. It can give you valuable suggestions on design.

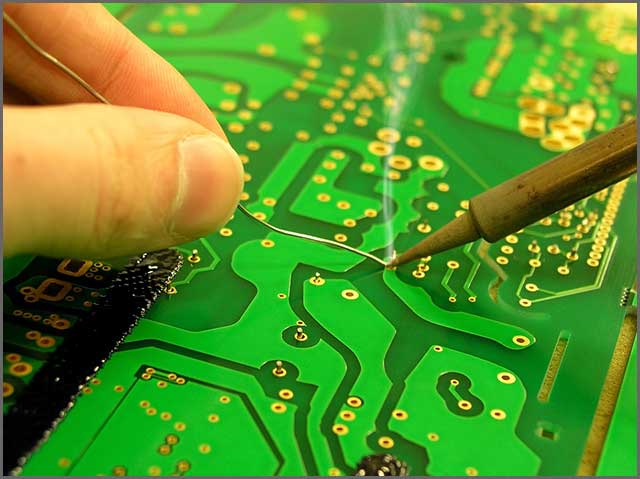

Image 2: PCB assembly

Image 2: PCB assembly

A lot of people make the mistake of getting in touch with their assemblers in the end. It can be a big mistake. Speaking in advance with your assembler would help you know more about the industry and available techniques and processes.

They can tell you about the latest PCB assembly trends and help you make the right decision. Plus, working with your assembler in advance would help you build a stable connection that will help you a lot when you finally move to the assembly phase.

4、PCB Assembly--Offshore Providers May Be Good, But Not Always

Many people opt for overseas assembly as it's more affordable. However, there are a lot of risks involved with offshoring.

Assemblers are known to use parts that are not of the right standard. That helps reduce costs but can cause you a lot of damage in the long run. You may end up spending more money, making offshoring a lousy option.

Other than this, there may be issues, including production delays, that may cause interruptions. Even a small delay can impact your timeline of events. Hence, it is essential to be careful when selecting to work with offshore assembly providers.

Special Offer: Get $100 off your order!

Please email [email protected] for details.

5、PCB Assembly--Dododododododonot Count on a Single Supplier

Do not make the mistake of counting on a single supplier. Always have a backup plan. Moreover, it would help if you were careful when designing the board. Try to make sure not to include parts that are not readily available.

6、PCB Assembly--Consider Naming and Labeling Parts

Most of us are taught to mark and label design documents, but very few draw and label the components.

It is essential to label, number, and match up all parts you include with your package. They should be very clearly mentioned so that there is no scope for error.

7、PCB Assembly--Don't Neglect the Design For Manufacturability Test

Design for manufacturing, also known as DFM, is an engineering test or process that describes engineering or designing a product to facilitate the manufacturing process. It helps reduce associated costs and makes the deal more feasible.

DFM can also help identify and solve potential problems to ensure the process goes smoothly. It is used in almost all engineering fields, and PCB assembly is no different.

A DFM check ensures the final product is up to the mark. Some problems can identify spacing issues, first pin indication, footprint corroboration, and component polarity.

You may have to hire experienced engineers to run a DFM review to ensure it gives correct results. You might not be able to review independently if you do not have the required tools, experience, and skills.

Moreover, some PCB assembly providers also offer DFM reviews. Get in touch with your provider to inquire if they provide such services or not. It will ensure you do not have to worry about testing or finding someone to conduct the required tests.

8、PCB Assembly--Recheck All Trade-offs

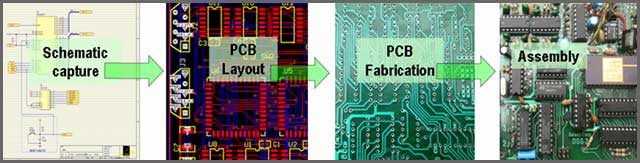

Image 3: PCB assembly

Image 3: PCB assembly

Technology is changing at a rapid pace. That is great for the business as we can get more out of doing very little now. However, there is always going to be a trade-off. After all, we want to push more and more features into boards that are getting smaller with each passing day.

Hence, you must know what you want from the board to get the required capabilities.

● Do you want more power?

● Do you yearn for a more robust transmission?

Consider the primary purpose of the board. It will help you determine the essential capabilities.

Do not let the trade-off scare you. You may have to scale back a little, but you will not have to drop everything. It is best to talk to your manufacturer and ask them for tips on improving the design to meet your requirements.

A well-designed and assembled board will offer more power and a more robust transmission with other features.

That is why it is necessary to be clear about your requirements before you start the manufacturing and assembly process so that the result meets your expectations.

9、PCB Assembly--Testing Before You Order

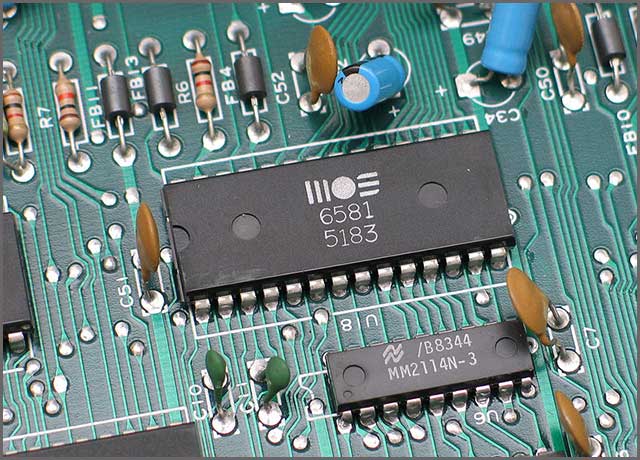

Image 4: PCB assembly

Image 4: PCB assembly

You might be able to get a discount if you give a bulk order, but it may not be a good idea unless you are sure about the quality of the final product.

It is best to try an assembler before moving ahead with a big order. It will ensure you have no difficulty in the end. Also, it's best to be in touch with multiple assemblers so that you can turn to the other one if the first deal falls flat.

Some experts even suggest hiring multiple assemblers and comparing the final product to make a decision.

It will give you a clear idea of how reliable a provider is. It is not only about the end product about the overall experience. Timing, for example, can make a lot of difference.

Video:

10、PCB Assembly--Conclusion

At OurPCB, we offer prototype PCB assembly services to all kinds of clients. We provide quick services – within 20 days – and have no minimum quantity requirements.

Call xxx today to have a conversation with one of our experts.

Special Offer: Get $100 off your order!

Please email [email protected] for details.