Engineers have learned to incorporate PCB prototyping into various design processes to evaluate their PCB-based products' functionalities. The system of prototyping is beneficial where failure after final production creates expensive rework and redesign.

PCB new inventions are essential intellectual property rights, and we need to consider many things in the entire industrial design process. We need to know what users want and what the product needs to succeed. We need to start making PCB prototypes, but what is the true meaning of prototypes? When should the prototype design begin? What is the best way to prototype your idea? As a PCB maker, how do we provide PCB prototyping? This article will give readers answers.

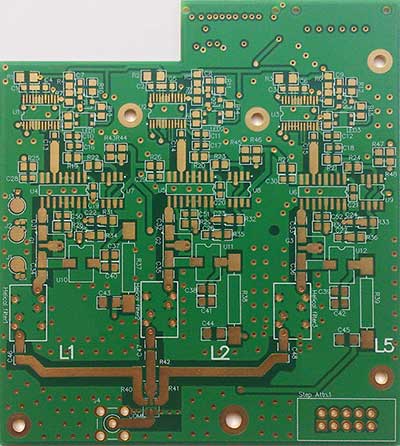

(Among PCB maker, high-quality PCB boards)

Contents

- 1. What Problems do PCB Products Need to Solve?

- Consumer Electronics:

- Medical Devices:

- Industrial Equipment:

- 2. How to Improve the Product You Want to Create

- 3.The Cost and Profit of PCB Product

- The Cost of PCB Product

- Size of board:

- The Size and Number of Holes in the Board:

- Custom Specifications:

- The Width of Signal Conductors:

- The Profit of PCB Products

- 4.Sketch For Designing PCB Products

- 5. Work With Excellent PCB Designer

- Designing a PCB Layout:

- Prototypes:

- Materials and Components:

- PCB Testing:

- 6.Building a 3D Program of PCB Prototype

- 7.Draw the appearance of the PCB Prototype

- 8.Building Cheap Models

- DIYs PCB Designs:

- Find Cheap PCB Makers:

- 9.Sign a Confidentiality Agreement With the PCB Supplier

- 10.Ensure the PCB Prototype Function is Normal

- Summary

Special Offer: Get $100 off your order!

Please email [email protected] for details.

1. What Problems do PCB Products Need to Solve?

(LAN and USB ports made by circuit board maker)

PCBs are essential parts of the electronics we use today across a wide range of applications. Some of those applications include:

-

Consumer Electronics:

From Smartphones to computers, remote controls, home appliances, and so on, a host of consumer products require PCBs to function today. Without PCBs, most consumer products used at homes and offices would be less efficient than today.

-

Medical Devices:

PCB applications include therapeutic equipment like Medical Imaging Systems (such as CT, CAT, and Ultrasonic Scanners), pulse and blood sugar monitors, pacemakers, and so on.

-

Industrial Equipment:

PCBs have become ubiquitous in industrial equipment. They are present in most of the material used in product manufacturing and supply chains, power generation and distribution, communications, and information technology.

As a PCB distributor, to make a useful PCB prototype for your circuit board maker, ensure you decide on the problem it needs to solve. Doing this will give purpose to your efforts, ensure your product meets your needs, and create a market of people with the same need for your product.

2. How to Improve the Product You Want to Create

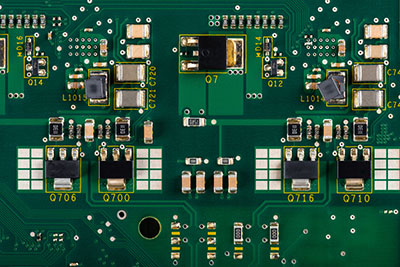

(Circuit board maker carrying out quality control procedure on a PCB)

Prototyping is one of the sure ways to increase the quality of the product you want to create. Use your PCB prototype to check for your PCB-based product's functionality before proceeding to large-scale manufacturing of the product.

It permits you to detect fault early during the development process and before you are invested an excessive amount of time and money into a flawed design. Quality PCB prototypes provide an explicit illustration of how your final product will perform. This way, you can assess if the product will meet your needs or not.

3.The Cost and Profit of PCB Product

(circuit board maker setting up an automatic PCB routing machine)

The Cost of PCB Product

We need to avoid the extremely high costs caused by unique or custom PCB design requirements. It recommended that PCB distributors subdivide PCB costs before mass production.

Some variable that may influence the value of the PCB product are listed below:

-

Size of board:

The number of circuit scale by commonly using a committee of the plate's desired device is determined. The more significant the board size is, the costlier it is to manufacture.

-

The Size and Number of Holes in the Board:

Super-thin holes require individual laser drills designed for drilling through multiple PCB layers, attracting more cost. Materials that are hard to dig will also increase PCB cost.

-

Custom Specifications:

Custom specifications will always raise the PCB cost, no matter the board size and layer. Special tools or production skills required to form a custom PCB will increase the PCB product cost. For instance, metal edging and rounded edges will include new charges, as does the employment of special board finishes.

-

The Width of Signal Conductors:

To forestall sudden surges and the threat of overheating, the signal conductors must have sufficient width. PCB makers will enlarge the conductor width and add extra solder mask to traces that may carry high signal, adding to the PCB cost.

The Profit of PCB Products

To estimate your profit margins, you must know the selling price and manufacturing cost of your product. Everyone within the distribution chain adds to the cost of a product to secure their profits. It is your responsibility to decide the amount of profit you want to make when retailing your product. Direct sales give you more flexibility in pricing, make your product more competitive, and allows you to urge more direct feedback from the buyer.

4.Sketch For Designing PCB Products

(3D circuit board manufacturer is computer software)

To start a PCB product design process, you need to draw a schematic circuit diagram. We can use PCB design software such as EAGLE, Altium, or Ki CAD to draw sketches. The schematic design is the foundation of other phases of your PCB design. PCB Sketching is a two-part process that involves drawing PCB components on the schematic sheet with the appropriate connections between them. PCB design software encompasses a library of components that may be wanted to make your desired circuit board.

You will derive your circuit board is a design position and adjust it according to requirements using PCB sketching software. The schematic will serve as a blueprint for laying out the traces and placing them on the PCB.

Special Offer: Get $100 off your order!

Please email [email protected] for details.

5. Work With Excellent PCB Designer

(A group of circuit board makers)

Follow the points below as we discuss the way to identify top-notch PCB designers:

-

Designing a PCB Layout:

Moving from a schematic to an actual PCB layout requires additional technical attention to style details. An excellent circuit board maker must keep a detailed eye on metrics and variables within the design layout.

-

Prototypes:

Circuit board makers must deal with problems of shrinking electronic components into circuit boards with efficient positioning. While satisfying the customer is specifications regarding dimensions, PCB designers should pay attention to PCB functions. Hence, ensure your PCB designer has time-proven prototypes available for you to examine.

-

Materials and Components:

If you trust your Pcb maker with component sourcing, ensure you know the source and quality of the materials. Ensure your manufacturer has chosen the best materials and components for your board.

-

PCB Testing:

Each stage of the PCB board design and manufacturing process must lead to the desired product. Therefore, choose a PCB manufacturer who will do the testing properly and correct any issue arising along the manufacturing process to avoid component wastage.

6.Building a 3D Program of PCB Prototype

(3D image of a circuit board made by a PCB maker online)

PCB prototyping has evolved over the last decade. Nonetheless, the method of manufacturing a PCB prototype still requires milling, drilling, film transfer, plating, and etching. Now, PCB prototyping may evolve even further with the emergence of PCB 3D design and 3D printing.

Advanced circuit board makers now make use of 3D-CAD software to create 3D Step files for PCB designs. The advent of 3D printing marked a new era in PCB development. What was once tagged too costly and time-consuming is now a production method that can save time, money, and resources. The 3D printer allows designers to print PCB design in-house as a PCB prototype. It will enable them to easily repeat their plans, improve their workflow and quality control, and achieve an overall faster time to market.

7.Draw the appearance of the PCB Prototype

(sketched diagram to make PCB online)

Before you start designing your PCB, it’s a good idea to draw your circuit board's appearance. There are several PCB makers, both online and offline, that allow you to bring the schematic presentation of your PCB prototype. Drawing the PCB appearance will inform the designer about your desire for the circuit board's shape and size.

8.Building Cheap Models

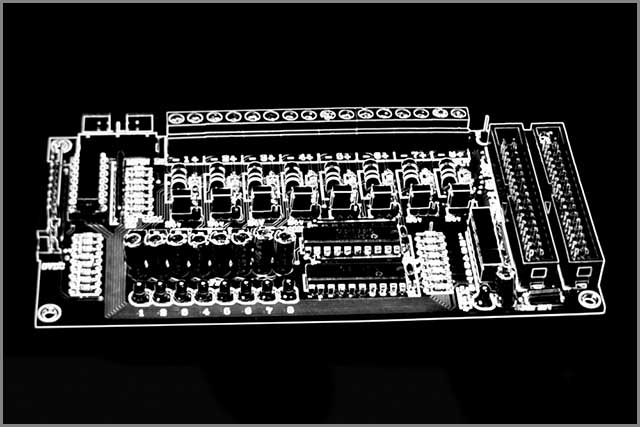

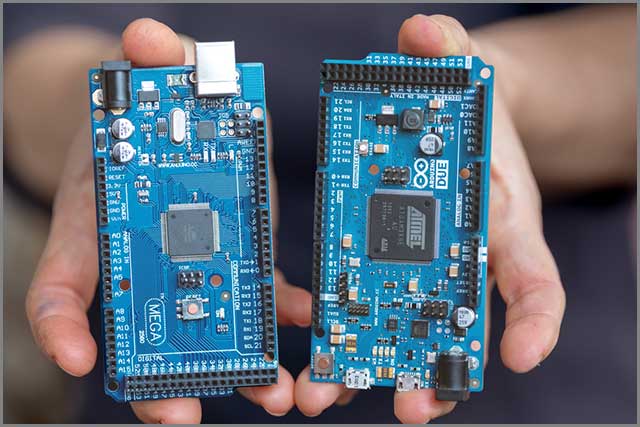

(Circuit board maker showing two different models of PCB)

In the quest for quality products for your project, the cost of producing different models is likely to be higher because you are determined to get the best result. The question is, how can you reduce the cost of production and still get the desired quality? Here are two ways to achieve your goals:

-

DIYs PCB Designs:

It is wise and essential to be able to design circuit board schematics yourself. There are several PCB makers online and design software, both free and paid, that are easy to use. This practice will cut the cost of paying a PCB designer.

-

Find Cheap PCB Makers:

There are still some manufacturers that will lower their rates without compromising the quality of your PCB boards. You should compare prices, delivery time, and quality of product from your selected PCB makers, and choose the one that best suits your needs.

9.Sign a Confidentiality Agreement With the PCB Supplier

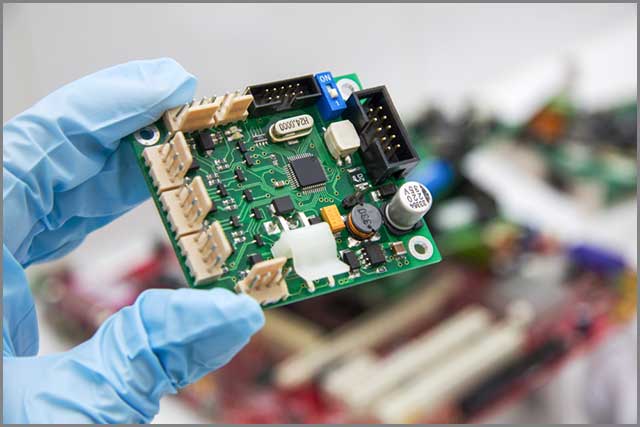

(PCB chip assembly held in hand by a PCB maker online)

It is vital to ensure that your PCB manufacturer is loyal to you and dedicated to your goals. One of the best ways to ensure this is by signing a confidentiality agreement with your PCB supplier. The Non-Disclosure Agreement (NDA) is also known as the contract, will define the relationship you expect from your PCB supplier.

The NDA is a single binding paper that keeps your PCB supplier checked and from stealing your design and ideas. Do not disclose too much information about your project before signing a foolproof NDA with the PCB maker. Confidentiality agreement helps you better design a prototype without fear of losing ground to your competitors.

10.Ensure the PCB Prototype Function is Normal

(Computer egg with circuit board displayed by a PCB maker online)

Testing the functionality of the PCB prototype helps to determine the steps to take towards the finished product. It helps you find fault in the production process or PCB component and ensure the final product's integrity. We have several PCB prototype tests that we can carry out to assess the functions of prototypes. These include functional test, in-circuit test, boundary scan, and manufacturing defects analyzers.

Summary

Whatever the purpose your PCB will serve for consumers, it is essential to be reliable, affordable and designed to fit your needs. Therefore, you need to consider your PCB business plan and create your PCB products with great attention to details.

Get yourself the best PCB maker you can find around to bring your goals to fruition. Contact us today at OurPCB, where quality service and technology meet the needs of both PCB beginners and professionals.

Special Offer: Get $100 off your order!

Please email [email protected] for details.