The Isola 370HR PCB is among a set of enhanced printed circuit boards. It is part of the new revolution of circuit boards in the PCB industry. Typically, conventional panels have a brittle nature. However, this special printed circuit board has reinforced glass-resin epoxy and traditional FR-4 materials. These additions help boost its thermal performance and moisture resistance properties.

You get to learn all the essential details of the Isola PCB. These include the features, benefits, and applications. Also, it covers other technical know-how PCB manufacturers and designers should know.

Contents

- 1. Isola 370HR Definition

- 2. Isola 370HR Features

- 3. Advantages of Isola 370HR

- 4. Which are the Types of Copper Foil Used in Isola 370HR?

- Reverse Treat Foil (RTF)

- HTE Grade 3

- 5. Thermal Analysis Techniques of Isola 370HR

- Differential Scanning Calorimetry (DSC)

- Thermal Mechanical Analysis (TMA)

- Thermal Gravimetric Analysis (TGA)

- Dynamic Mechanical Analysis (DMA)

- 6. What is the suggested Heat Ramp Rate of Isola 370HR?

- 7. Isola 370HR Sequential Lamination

- Multiple layer count

- Blind via boards

- Standard HDI

- 8. What are the Applications of Isola 370HR?

- 9. How does Isola 370HR differ in Terms of Peel Strength and Flexural Strength?

- Peel Strength

- Flexural Strength

- 10. How to create holes in Isola 370HR?

- 11. FAQ Isola 370hr PCB

- What is the ideal weave style for Isola 370HR?

- Which is the Type of Glass Fabric utilized in Isola 370HR?

- How would you Control Skew Due to the Fiberglass Weave of Isola 370HR?

- Are there Quality Certifications for Isola 370HR?

- Which is the Preferred Method of Desmear for Isola 370HR?

- Is Isola 370HR Combustible?

- Conclusion

Special Offer: Get $100 off your order!

Please email [email protected] for details.

1. Isola 370HR Definition

Isola 370HR is a high-performance PCB built with FR4 multifunctional epoxy resin. It is a standard part of the multilayer printed wiring board. Additionally, it is explicitly intended for multi-facet PCB applications. Unlike other conventional panels, the material of Isola PCB has enhanced features. For example, it has UV blocking and CAF resistance properties. Likewise, the laminate board highlights incredible thermal reliability.

This overlay adds epoxy resin to an E-glass fabric texture. Likewise, it is primarily responsible for the increased thermal dissipation and Fr-4 system processability, and a low CTE.

Moreover, this laminate's thermal and mechanical results surpass the usual FR-4 materials. Hence, Isola PCB is viable with Automated Optical Inspection (AOI) applications. It also works excellently for designs that require sequential lamination.

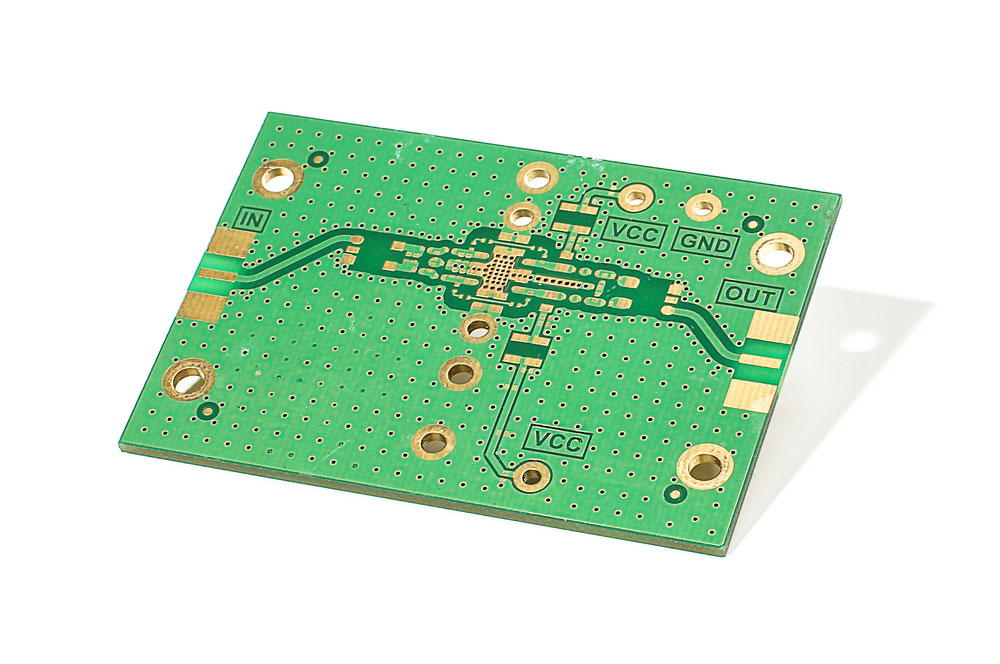

(Laminated Isola 370HR PCBs)

2. Isola 370HR Features

- The core material is available in sheet structures and regular boards.

- It is viable with lead-free coupling and FR-4 processing.

- Its standard thickness is between 0.05 mm (0.002cm) and 3.5 mm (0.125cm).

- The product is eco-friendly and compliant with RoHS.

- The prefabricated structure is in a board or roll structure.

- CAF Resistant.

- Glass fabric is available.

- Dielectric properties and thermal resistance make this board great for high-temperature applications.

- The decomposition temperature (Td) is high.

- Likewise, it has an extremely high glass change temperature (Tg).

- Blocks UV rays.

- The CTE has a low Z-axis.

(Isola 370HR is RoHS Compliant)

3. Advantages of Isola 370HR

Isola 370HR PCB material has the following advantages:

- The prepregs and laminates guarantee top thermal results with a small Thermal Expansion Coefficient.

- The mechanical, chemical, and moisture resistance levels are high. They often exceed the abilities of other FR-4 materials.

- In addition, Isola PCB offers laser fluorescing and UV impeding. These features make it a standard application in optical positioning and solder mask imaging.

- It has high throughput accuracy when gathering and creating Isola printed circuit boards.

- Also, it has excellent handling of FR4 processes.

(Epoxy on a PCB)

4. Which are the Types of Copper Foil Used in Isola 370HR?

-

Reverse Treat Foil (RTF)

Copper foil with an RTF profile helps electrodeposited copper look smoother. The film is a soft yet gritty covering that adds to the substrate grip of the Isola PCB dielectrics.

Standard RTF improves the Roughness Surface Area Ratio slightly from 1.0 to 1.2. This profile copper foil type is as expensive as Electrodeposited copper. However, its peel strength is poor. Therefore, it is vulnerable to cracks and laminations.

-

HTE Grade 3

This profile copper foil type stands for High Elongation Electrodeposited copper. It is a pure form of copper foil rated IPC-4562 Grade 3. Though, the exterior face of the foil is semi-matt.

It has an anti-tarnish treatment to limit erosion and oxidation. Further, the matt face of the foil gets Zn/Cr treatment to increase the bond to prepreg products.

(A roll of copper foil)

5. Thermal Analysis Techniques of Isola 370HR

The standard thermal analysis methods for Isola PCB laminate products include:

-

Differential Scanning Calorimetry (DSC)

DSC is the most well-known technique for thermal analysis. It is essential to monitor Isola PCB glass transition temperature.

Unlike the others, it checks the heat entering and leaving the PCB laminate. It uses a temperature range where the particles of 370HR epoxy resin change from rigid and brittle to flexible and robust.

A delta Tg under 5 degrees Celsius is ideal for a complete fix. However, test variations suggest a standard deviation of 1.5 to 2 degrees Celsius. As a result, avoid overestimating the DSC test results.

-

Thermal Mechanical Analysis (TMA)

With TMA, measuring the Isola 370HR glass laminate temperature is easy. Typically, it estimates the Tg by deciding on the PCB material extension. And this glass transition temperature, Tg, changes with a thermal expansion rate along the Z-axis CTE. Unlike pre-Tg, many thermoset material types like 370HR expand by up to 500% post-Tg.

-

Thermal Gravimetric Analysis (TGA)

TGA helps estimate the breakdown temperature of the Isola PCB material. Breakdown temperature, in this case, causes a 5 percent reduction in the weight of the Isola material. This thermal analysis strategy decides the temperature against the weight change.

Further, the breakdown of a PCB material occurs over a broad scope of temperatures. And this breakdown results from the behavior of chemical bonds in polymers.

In general, Isola PCBs with high breakdown temperatures have high thermal stability. By contrast, low thermal stability is also for standard breakdown temperature PCBs.

-

Dynamic Mechanical Analysis (DMA)

DMA estimates the released energy or damping. It also checks the Young's Modulus properties of the Isola PCB under occasional strain.

The analysis gives quantitative and qualitative data concerning the Isola PCB materials. It is essential to classify the mechanical elements of viscoelastic polymeric PCB materials. These materials, therefore, help to tell the impact of temperature, frequency, and time.

UsuThe DMA is the most appropriate technique for measuring the Tg dissipation factor of Isola PCB systems. Ally, the Tg results of DMA are higher. And it exceeds DSC by a range of 5 to 15 degrees Celsius.

Special Offer: Get $100 off your order!

Please email [email protected] for details.

6. What is the suggested Heat Ramp Rate of Isola 370HR?

Isola 370HR has an extensive heat ramp rate scale. For better results, there are different lamination designs.

A low range is found in majorly the low and mid-level Isola items. Similarly, the PCB material's rheology behaves closely. An intense heat ramp rate has a high viscosity and vice versa. So, the standard heat ramp rate is between 2.0 and 6.0°C every minute.

Higher rates above 3°C/min have a more comprehensive processing range. In the same way, items requiring significant sap filling (equivalent to/more than 2 Oz copper) must run >3.5°C /minute.

The base temperature often reaches 200 degrees Celsius. So, when using oxides, this temperature helps fulfill the requirements of the heat ramp.

7. Isola 370HR Sequential Lamination

Sequential lamination has different techniques. But, it generally involves adding a laminate subpart to an outer layer of copper. The practical methods in sequential lamination are as follows.

Multiple layer count

This item includes a thicker subpart which has around 4 to 30 layers. Likewise, it contains around two consecutive hardware layers on each side. The central Isola PCB core utilizes covered vias.

Blind via boards

This technique combines the subparts. But, it fixes the subparts on the outer piece of the finished Isola PCB. Afterward, you create a connection by drilling a hole through the panel and the complete board.

Standard HDI

The core of an Isola PCB is naturally thin. And this center is up to 4 layers. Also, the center has up to 3 sequential circuit layers per side. Micro vias interface with the outside layers. These features, therefore, put a standard HDI as the most popular sequential lamination method for Isola PCB.

(A heap of broken PCBs showing laminate fibers).

8. What are the Applications of Isola 370HR?

Isola PCB materials are helpful in high-reliability applications like:

- Consumer hardware.

- Processing, Storage gadgets, and Peripherals.

- Defense and aerospace applications.

- Organizing and Communication Systems

- Transportation and automotive applications.

- Clinical, Industrial, and Instrumentation.

(Most clinical instruments use the Isola 370HR)

9. How does Isola 370HR differ in Terms of Peel Strength and Flexural Strength?

-

Peel Strength

The Isola laminate peel strength connects the copper conductor and the electrically conductive material. It is the average load per conductor width needed to separate compact materials. Though, the angle of separation stands at 180 degrees. It works under three conditions: Post thermal stress, at increased temperatures, and after exposure to chemical processes.

-

Flexural Strength

Material can withstand the mechanical strain. Force per unit area is the standard unit of measurement.

Typically, the test involves balancing the PCB board at the sides and weighing a load down the middle. IPC4101 determines the base flexural strength of various base materials employed in multilayer PCBs and rigid panels.

10. How to create holes in Isola 370HR?

(A CNC machine drilling a PCB material).

The 370HR material has excellent thermal performance. Thanks to a resin system, it also has prominent modulus properties.

Unlike other FR406 materials, there is less debris from drilling Isola PCBs. In addition, the drill debris remains as lingering particles with little effect on the drill volumes. These PCB factors are also due to the presence of thermal decomposition of the resin content.

However, eliminating this resin debris requires using top helix tools with angled drill patterns. Unless you are drilling larger hole sizes, employ backer and entry materials. Generally, these tools prevent fracturing the whole perimeter.

In addition, using a sharper plunge focus helps you avoid crazing the secondary drill hole perimeter. Meanwhile, thicker Isola 370HR boards with heavy copper or invar as cladding need lighter drill options.

The drill boundaries depend on the dull tool, plan, and fix quality. Finally, a drill tip spins up to 170m/min from 110m/min. Meanwhile, the chip load goes at 60 to 75 microns per revolution.

11. FAQ Isola 370hr PCB

-

What is the ideal weave style for Isola 370HR?

Ideally, the ideal weave style for Isola 370HR PCBs is the square weave. This weave style has a uniform yarn count. Likewise, it includes a consistent pitch throughout.

-

Which is the Type of Glass Fabric utilized in Isola 370HR?

It utilizes Standard E-glass, Square weave glass texture, and Spread glass texture.

-

How would you Control Skew Due to the Fiberglass Weave of Isola 370HR?

- Choose an angle and course the differential matches in the Isola PCB epoxy laminate to the glass square weave.

- Pivot the design at a point to the weave while manufacturing each Isola PCB laminate.

- Route every individual pair with a comparative pitch similar to the glass fibers.

- In addition to the resin system, use a low dielectric constant glass.

- Finally, use the glass weave style and spread the fiberglass evenly, like 1086, 1078, and 1067.

-

Are there Quality Certifications for Isola 370HR?

Indeed, the super quality certificates your Isola 370HR PCB material requires are:

- ANSI certificate.

- ASTM Certification.

- IEC Certification.

- IPC certificate.

- ITAR Certification.

- REACH certificate.

- UL Certification.

-

Which is the Preferred Method of Desmear for Isola 370HR?

Plasma desmearing is the most suitable 370HR Isola PCB desmear method. This strategy is ideal for thicker PCBs with a high aspect ratio.

-

Is Isola 370HR Combustible?

Although it is very reliable and ensures good thermal qualities, the combustibility rating of the Isola PCB is UL94 V-0. A UL94 V-0 certification indicates that burning materials go out in less than 10 seconds. Therefore, it leaves the particles non-flammable.

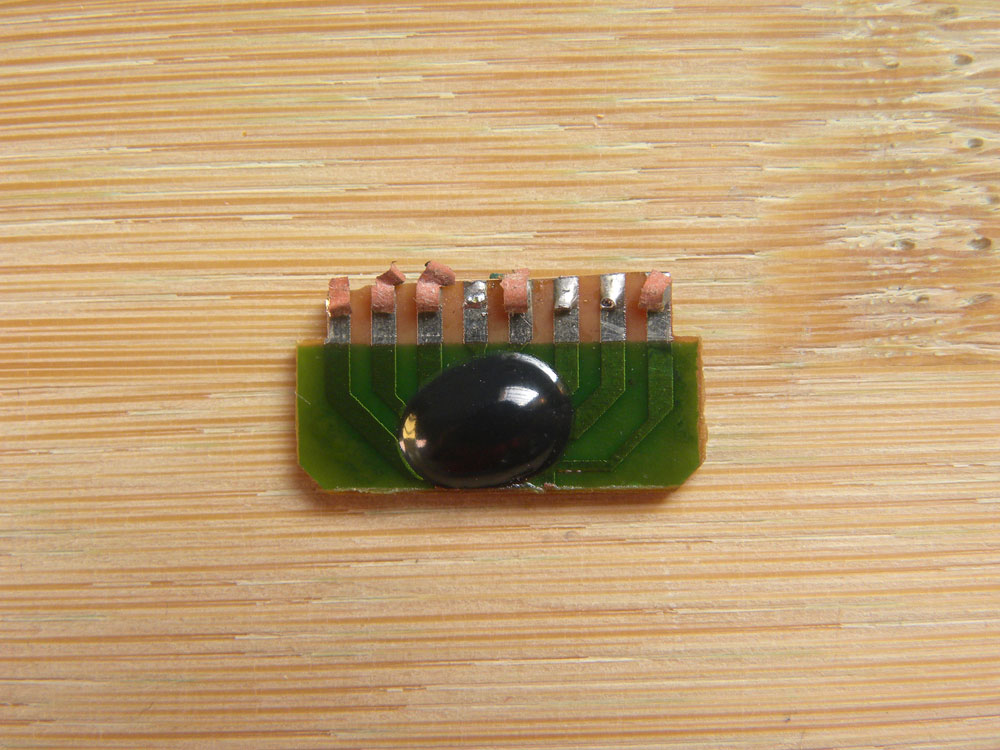

(A flame-resistant printed circuit board).

Conclusion

The Isola 370HR laminate is a durable PCB design material with proven performance. It features excellent thermal performance and electrical insulation properties. Hence, the printed circuit board is helpful in many markets.

You may need further information and guidance on similar PCB materials. Therefore, if you ever need help getting quality PCB products such as the Isola 370HR laminate, contact us.

Special Offer: Get $100 off your order!

Please email [email protected] for details.