Wave Soldering vs Reflow is two types of soldering. By soldering, you can join two or more different metals by melting the solder (filler metal). Solder paste is a metal alloy made of tin and lead. It is decomposed by using heated iron, which is usually 600°F.

However, there are two main soldering processes used for commercial purposes. They are Reflow Soldering and Wave Soldering.

Reflow soldering meets the needs of today’s production of electronics. The soldering also provides dependable soldering for all forms required component and pad sizes.

For many years, reflow soldering has become the most used form of soldering for the Printed Circuit Board (PCB) assembly.

Reflow soldering provides high quality. It is easy to control and monitor.

In this article, we will compare the reflow soldering vs. wave soldering. Without further ado, let us commence.

Contents

- Wave Soldering vs Reflow: What is Reflow/Wave Soldering?

- What is Reflow Soldering?

- What is Wave Soldering?

- Wave Soldering vs Reflow: Soldering process

- Wave Soldering vs Reflow-- How Does Reflow Soldering Work?

- Apply flux

- Apply the Solder Paste

- Place Components

- Reflow Soldering

- Inspect the Printed Circuit Board

- Wave Soldering vs Reflow

- -- Conditions For Effective Reflow Soldering Process

- A suitable Reflow Soldering Oven:

- Infrared Convection Oven:

- Vapor Phase Oven:

- Follow Required reflow soldering temperature:

- Printed circuit board footprint:

- Choose high-quality solder paste:

- A High-Quality PCB stencil:

- The placement of surface mount components:

- Conclusion:

Wave Soldering vs Reflow: What is Reflow/Wave Soldering?

What is Reflow Soldering?

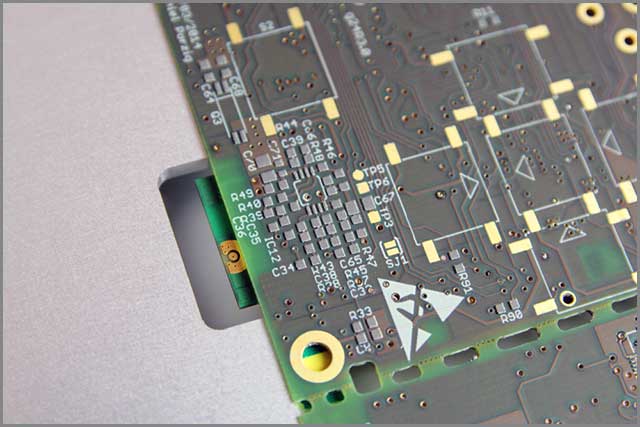

Reflow soldering is the process of attaching surface components to the printed circuit boards (PCBs).

We call this process infrared reflow soldering. Also, the basics of this process’s basics require the application of solder paste to the board’s relevant areas.

The PCB assembly then passes a tunnel where the board. Here, it heats up to a controlled manner. Thus the solder paste melts without getting damage from overheating. It is essential to secure the printed circuit board (PCB) with the use of electrics.

The reflow soldering process is a reliable solder surface mounts component. It is well suited, especially on those excellent pitch leads. Which makes it ideal for ingredients used in mass electronics products?

What is Wave Soldering?

Wave soldering is essential in the combination of PCBs. That happens through the use of a liquid wave formed due to motor agitation and the liquid. Both compounds dissolve into the tin.

The wave soldering process is mandatory for surface-mount technology (SMT) and the through-hole printed circuit assemblies. In the SMT, the component sticks to the surface of the PCB. It happens through placement before it runs through the melted solder wave.

Most times, wave soldering made use of the through-the-hole components.

Wave Soldering vs Reflow: Soldering process

Special Offer: Get $100 off your order!

Please email [email protected] for details.

Wave Soldering vs Reflow-- How Does Reflow Soldering Work?

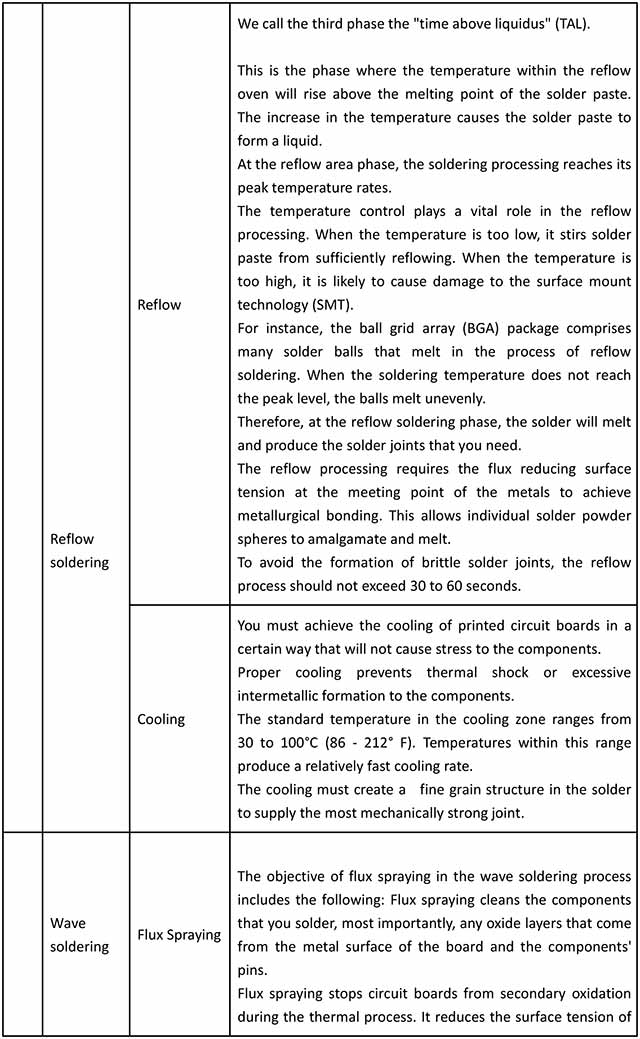

The reflow soldering is an effective process for soldering the printed circuit boards (PCBs) with the surface mount technology.

Before we dive into the workings of reflow soldering, you require specific tools for the process. They include:

- A syringe with solder paste

- Flux

- Tweezers

- A real reflow oven/ toaster oven/ A skillet.

Now that you know the tools required for the reflow soldering process, let’s get how Reflow soldering works.

Apply flux

Apply flux to the pads to get started with the process. This makes the place clean and gets a decent amount of heat.

Apply the Solder Paste

After you’ve applied the flux, it’s time to use the solder to every single pad. You don’t have to be precise in the way you use the solder paste.

When the paste melts, it flows to where it belongs.

Place Components

Take the surface mounts components and place the surface mounts components one after another using tweezers.

When the paste melts, the surface mounts components will straighten on its own. However, straightening the details as precisely as possible.

Reflow Soldering

Now that you have the surface mounts, it’s time for the reflow process.

The process’s primary objective is to heat the PCB to a specific temperature. That is a temperature where the paste melts, and it cools down naturally. Professionals make use of a particular profile of weather to make sure that the pastes melt correctly. This profile also prevents any damage to the components that might occur in the process.

The apex temperature rise rate of 220 to 250°C is suitable for the reflowing soldering process.

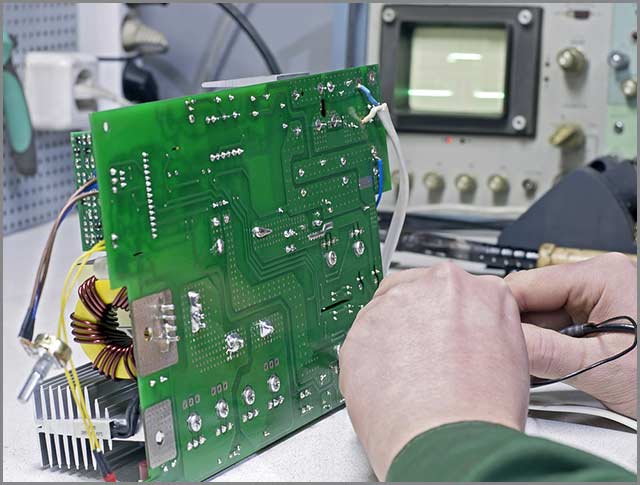

Inspect the Printed Circuit Board

After the printed circuit board (PCB) cools, inspect it to ensure there are no irregularities.

Watch out for breaks in the solder paste, poor and missing solder joints. As well Here’s a short video of how the reflow soldering process works.

Wave Soldering vs Reflow

-- Conditions For Effective Reflow Soldering Process

-

A suitable Reflow Soldering Oven:

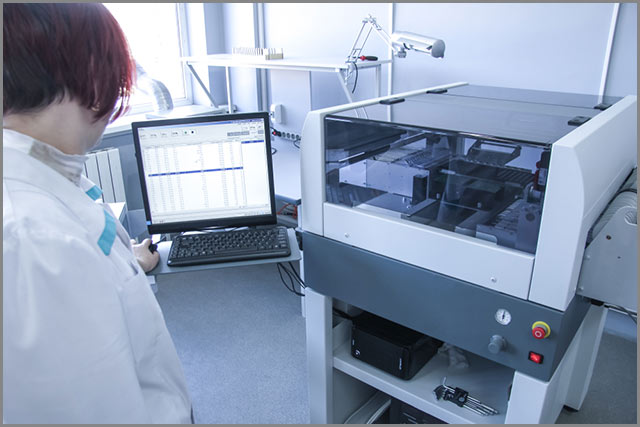

A reflow soldering oven is a machine that allows for the reflow soldering of surface mount components to PCB.

Reflow soldering ovens come in sizes and types. The following are the different types of reflow soldering ovens:

-

Infrared Convection Oven:

There is heat transfer in the oven to the surface mounts components. The transfer also happens in the solder paste through the radiation of heat from the heating elements.

It has a fan that provides circulation to improve the efficiency of the transfer of heat.

-

Vapor Phase Oven:

The oven uses the thermal energy in a layer of vapor to achieve soldering. There’s a liquid perfluoropolyether that helps produce a vapor layer in which the printed circuit boards immerse.

-

Follow Required reflow soldering temperature:

Almost all solder paste melt around 180 to 190°C (approximately 360 to 370°F. You have to get the solder paste hotter than this to get to the desired result.

-

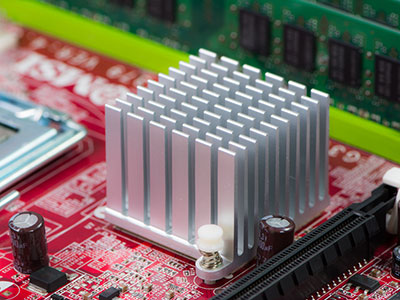

Printed circuit board footprint:

In the printed circuit board’s designs, the footprint is a pattern from the electronic component. That goes through the soldering process.

We call this the footprint landing patterns.

It could be a broad ball grid array (BGA), a through the hole connector, or a surface mounts capitation. The footprint is a prerequisite for all the parts that you solder into a PCB.

-

Choose high-quality solder paste:

Choosing a soldering paste can either make or break an assembly process. When you choose the right solder paste for the process, you minimize complications with the process consistency and the solder joint’s quality.

-

A High-Quality PCB stencil:

A printed circuit board (PCB) stencil is a sheet of stainless steel with laser-cut openings. You place this opening in solder on the PCB for surface mount component placement.

The stencil is to deposit solder paste on the selected places on the bare of the printed circuit board. That makes the PCB align perfectly.

The PCB stencil’s primary function is to accurately deposit the right amount of solder on the surface mounts technology pads. That allows the solder joints between the places and the component to be perfect. With this, users get excellent mechanical strength and electrical connection.

-

The placement of surface mount components:

This does not only affect the time it takes to assemble the printed circuit boards. It, however, determines the reliability of the board.

The proper placement of the surface mount component is essential to the functioning of the printed circuit boards.

Conclusion:

Soldering is essential in pcb manufacturing.

In this article, we compare two types of soldering: Reflow soldering and wave soldering. We discussed steps to follow when observing the two soldering processes. Here, we mentioned the required temperature rise rate.

With easy-to-understand guidelines, engineers, designers, and start-up tech companies will know how the reflow soldering process works. You will also get to know all the tools you need for the entire process at the end of this post.

However, it is not mandatory to use the reflow soldering oven. There are other options like skillets and hot plates.

Lastly, we look at some of the conditions for an effective reflow soldering process. Some of these conditions involve temperature rise, oven temperature. And it would help if you chose high-quality solder paste to ensure the reflow process’ effectiveness.

Special Offer: Get $100 off your order!

Please email [email protected] for details.