Most mobile devices draw their power from rechargeable lithium batteries. These power sources require a management system because they are sensitive to various factors, such as overcharging. PCB batteries can manage these batteries, and the acronym has a different meaning. While it is a printed circuit board, the term stands for Protection Circuit Board in this case. In this article, we will look at the functions of the PCB batteries and how it compares to their "big brother," the BMS. Let's get started!

Contents

Special Offer: Get $100 off your order!

Please email [email protected] for details.

What is a PCB Battery?

A PCB (Protection Circuit Board) battery is the "brain" in small, digital batteries. Also known as a PCM (Protection Circuit Module), the PCB protects these rechargeable batteries from overcharging, over-current, short-circuiting, and over-discharging. Most of these compact batteries have voltages varying from 3.7-7.4V and are typical in mobile phones, music players, GPS, cameras, etc.

A phone battery

How a PCB Battery Protects the Battery

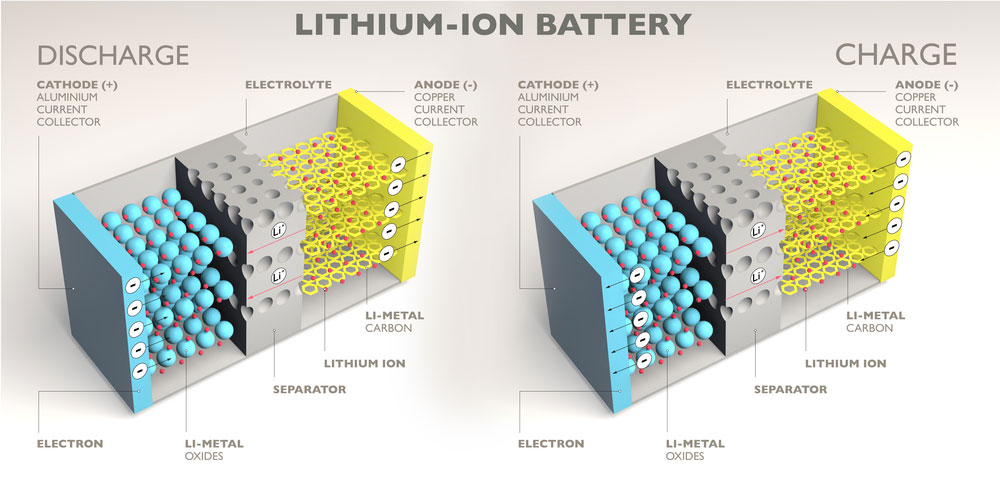

In a lithium-ion battery, the electrons go to the anode and cathode when charging and discharging. The PCB battery limits the battery's voltage from exceeding 4.25V when recharging to avoid overcharging. If it overcharges, the following scenarios can occur.

- Anode structure collapsing

- Short-circuiting

- Hard crystal formation

- Rising internal temperatures

- Fire

A lithium-ion battery in its charging and discharging states

Over currents will also cause temperatures to rise, leading to fires. Over-discharging has negative effects, as well. It can cause the battery to lose its capacity ratio permanently. The lowest voltage in lithium-ion batteries is usually 2.7V, but over-discharging can lower this figure, causing permanent damage.

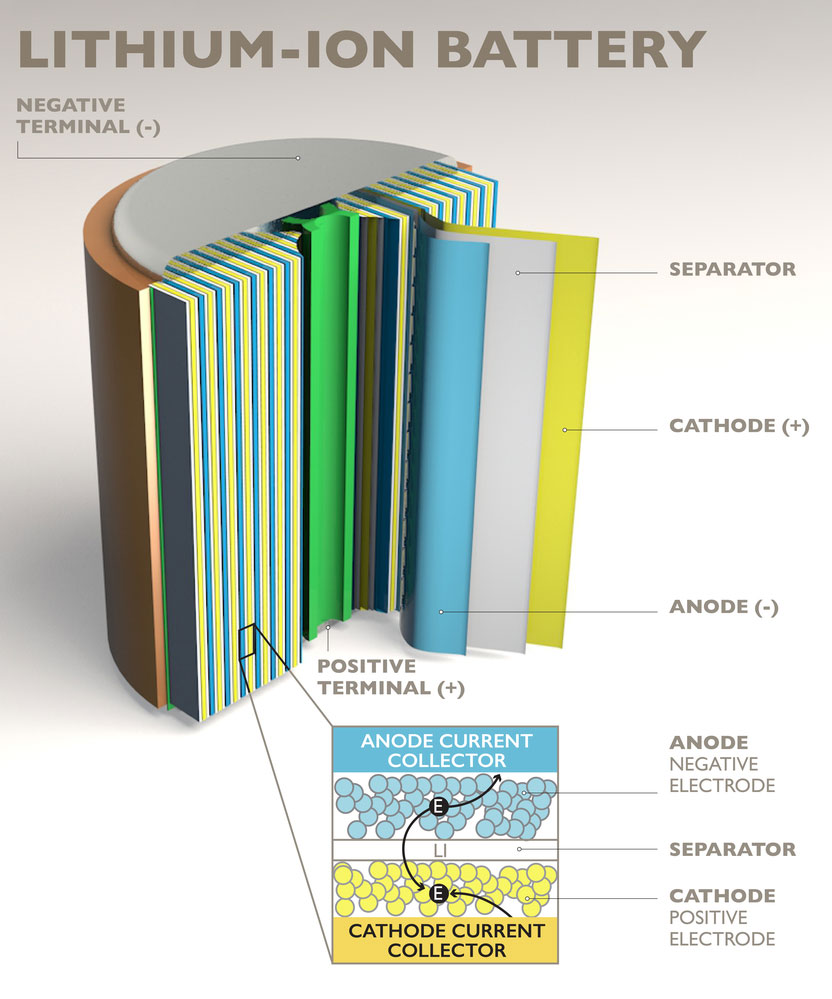

A lithium-ion battery

PCB Battery Equilibrium Protection Function

The protection board features an equilibrium protection function with two operational modes.

Energy Conversion Equilibrium

This equilibrium refers to transferring a large-capacity battery to a small one (in energy storage terms). Divided into fixed-point and capacity constant balance, the purpose of this function is to detect the balance in battery capacity.

Rechargeable lithium-ion phone batteries

Energy Consumption Balancing

Energy consumption balancing has three categories.

- Charging equilibrium: If the voltage of any battery cell is higher than the battery's average voltage when charging, the circuit board initiates equilibrium protection.

- Fixed-point voltage equilibrium: After battery charging, the charge management board gets set to begin balancing at a fixed voltage point. And at a shorter equalization time.

- Static automatic balancing: This equilibrium gets carried out when charging/discharging, even if the battery cell is in a static store state. If the voltage is inconsistent, the battery PCB will initiate equilibrium protection to make it consistent.

Special Offer: Get $100 off your order!

Please email [email protected] for details.

Battery PCB vs. BMS

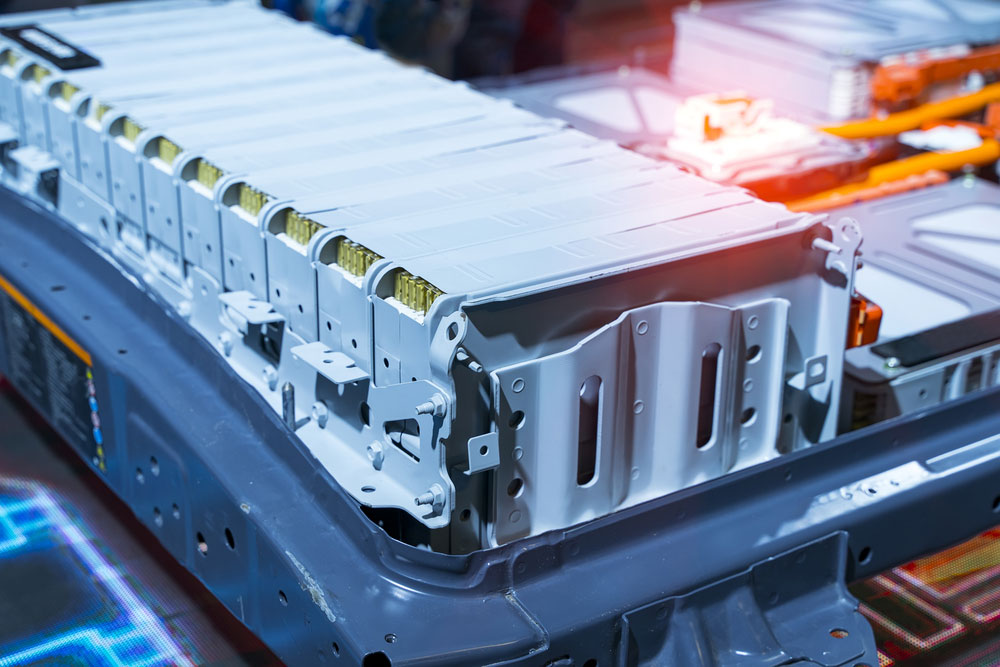

PCBs or PCMs are ideal for small low-voltage battery packs with less than 20 cells. On the other hand, BMS (Battery Management Systems) are suitable for managing high-voltage lithium battery packs with over 20 cells. The system can monitor each cell's operation to ensure safe running.

Multiple large-capacity batteries in a green energy plant. Such a unit requires a battery management system.

A BMS operates like a PCB but with advanced safety and protection features. For instance, it monitors the battery in real time, calculates & reports secondary data via designated software, and controls the battery's environment.

To be more specific, the Battery Management System keeps tabs on the battery's state in the following areas.

- Temperature: Individual cell temperature and average battery temperature

- Voltage: Individual cell voltage and total battery voltage

- State of Health (SoH): A predefined measurement of the battery's overall condition

- State of Charge (SoC)/Depth of Discharge (DoD): Indicates the battery's charge level

- Current: Current flowing into and out of the battery

- Coolant flow: Only for fluid-cooled batteries

A lithium battery pack used in an electric car

BMS Modules

A Battery Management System contains the following five modules.

- Control module

- Display module

- Wireless communication module

- Management system

- Collection module

Differences Between a Battery PCB and BMS

Besides the battery pack size they manage, these battery protection devices have the following differences.

Hardware Components

Protection circuit boards contain MOS tubes, integrated circuits, and capacitive & resistive components. A BMS is more advanced because it features a microcontroller integrated with intelligent software to act as the system's brain.

Precision

A circuit protection module cannot assess the accurate status of the battery pack's charging level. However, a BMS calculates, monitors, and interprets different measurements, such as the battery charge state and health.

Modern metal lithium-ion battery cells

Steering

PCBs cannot steer consuming or charging units. But a BMS features MODBUS, I2C, and CAN communication buses that enable it to run these units. This steering allows the optimization of battery utilization and system behavior. A typical consuming component steered by the BMS is an electric motor.

Operation Under Low Temperatures

Although BMSs have more features and operate better than PCBs, they are unstable at low temperatures.

Cost

BMS is costlier than PCB.

PCB/PCM vs. BMS: Which One Is Better?

It depends on your battery pack size and the required protection level. PCBs or PCMs are suitable for small battery packs with 20 cells or less, such as mobile phone batteries. And they only offer essential protection for these digital batteries. But BMSs offer more sophisticated checks to monitor the battery precisely in many aspects. However, they are ideal for large battery packs with over 20 cells.

An EV battery with multiple cells

Conclusion

In summary, PCB batteries are essential for safeguarding small digital batteries from overcharging, over-discharging, shorts, and over-current. These compact batteries are typical in portable devices, so they need a small protection system with few hardware components to fit inside the gadgets. And a PCB/PCM fits the bill. That's it for this article! Drop a comment if you have any questions, and we'll get back to you in no time.

Special Offer: Get $100 off your order!

Please email [email protected] for details.