In the PCB industry today, there are significant enhancements, such as in the FR4 TG130. This unique board is CAF resistant and helps electronic circuits withstand high temperatures up to 130 degrees Celsius. Therefore, it cuts out fire risks, electronic damage, and other losses.

As you read, you learn all the essential details concerning the standard FR4 TG130 board. These details give you a better idea of the board's electrical properties, mechanical properties, cost factors, and more.

Contents

- What is FR4 TG130?

- Essential data for Standard TG130 PCB

- Laminate requirements

- Minimum peel strength

- Minimum volume resistivity

- Minimum surface resistivity

- Maximum moisture

- Permittivity and the minimum arc

- Minimum flexural strength

- Minimum thermal stress

- Advantages of FR-4 TG130

- High insulation properties

- The low water infiltration rate

- High Arc Resistance

- Great aspects of manufacturing

- When Would it be a Good Idea for You to Utilize FR-4 TG130?

- What is the testing technology of Fr4 Tg130?

- Dynamic Mechanical Analysis.

- Thermal Mechanical Analysis

- Differential Scanning Calorimetry

- Factors Influencing the Cost of Tg130 PCB

- The type of material.

- Size

- Utilization of the working panel

- The design

- Hole size

- Delivery time

- FAQ about FR4 TG130

- Which Solder Masks work best with FR4 Tg130?

- What Time is the Most Appropriate for the Use of FR4 Tg130?

- Are there other Substitute FR4 Materials Asides from FR4 Tg130?

- What is the right thickness of the FR4 Tg130 Board?

- Conclusion

Special Offer: Get $100 off your order!

Please email [email protected] for details.

What is FR4 TG130?

FR4 TG130 is a particular printed circuit board reinforced to avoid overheating, melting, or burning up to 130 degrees Celsius. This way, the glass change temperature (Tg) acts as a printed circuit board's mechanical stability for longer shelf life.

Meanwhile, the FR4 is one of the base materials of the circuit board. Together with epoxy resin, it helps ensure mechanical strength and chemical resistance. This composition, therefore, makes the FR4 tg130 flame resistant. In other words, it enables the circuit boards for high operating temperatures.

(A circuit chip with epoxy resin adhesive).

Essential data for Standard TG130 PCB

Laminate requirements

This requirement during lamination relies upon the PCB board thickness. The tg130 PCB often has an average board thickness of 0.5mm. However, you have a choice of customizing the board thickness based on the tg130 printed circuit board function.

(A laminated fiberglass PCB).

Minimum peel strength

This requirement states the mechanical strength of a material. It also depends on the thickness range of the finished product. For example, board raw materials made from fiberglass cloth display better peel strength.

Minimum volume resistivity

It denotes resistance to water molecules. Typically, the standard tg130 PCB demonstrates C-96/35/90, a higher temperature range E-24/125, and post-humidity conditioning. All these class values, however, rely upon the board material and thickness.

Minimum surface resistivity

It refers to the resistance between the layers of the board. In this case, three PCB classes are available for tg130. They are the C-96/35/90, higher temperature E-24/125, and post humidity conditioning.

Maximum moisture

This condition relates to the absorption of moisture of various values. The board thickness also determines maximum moisture absorption.

Permittivity and the minimum arc

The copper thickness determines the dielectric constant and hence, the electrical strength. These conditions also apply to the other standard tg130 board requirements.

Minimum flexural strength

It has two sections of length and cross directions. And they vary in specifications based on the thickness of the tg130 board, particularly when it exceeds 0.5mm. It contributes to the board's ability to withstand mechanical stress.

Minimum thermal stress

It relates to the temperature requirements of the board. It also depends on the tg130 board thickness. A thicker board withstands thermal stress better than a thinner tg130 PCB.

Advantages of FR-4 TG130

The FR4 Tg130 printed circuit board comes with different advantages such as:

High insulation properties

The fr4 Tg130 has insulation against electric current leaks because of its high protection properties.

The low water infiltration rate

The fr4 Tg130 PCBs are valuable in applications in a moist environment. In other words, they help block water entry into the PCB.

High Arc Resistance

This feature contributes to the electrical properties of the board and its temperature resistance. Here, the Tg 130 helps to insulate against surface discharges. Therefore, it has a high arc resistance of about 10 mA.

Great aspects of manufacturing

Assembling FR4 Tg130 is easy because of its unique angles. Additionally, the fr4 Tg130 printed circuit board is well known to manufacturers. As a result, it is easy to produce.

Special Offer: Get $100 off your order!

Please email [email protected] for details.

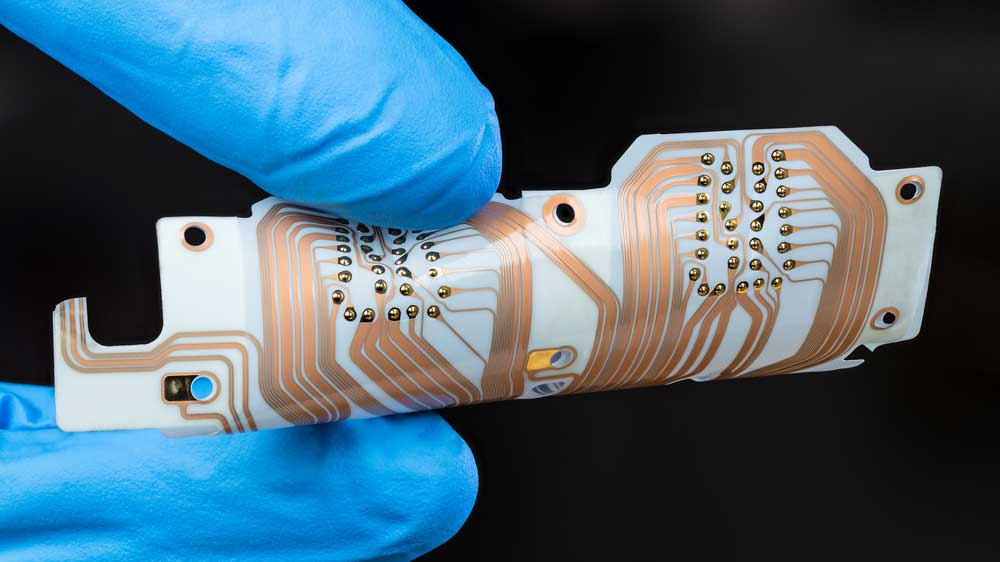

When Would it be a Good Idea for You to Utilize FR-4 TG130?

It is suitable for most situations where you want a rigid-flex PCB or when you are building an item around a PCB. The fr4 Tg130 is the best material for single-sided PCBs and multilayer PCBs.

(A rigid-flex PCB).

What is the testing technology of Fr4 Tg130?

There are three major technologies for testing the glass transition temperature of a PCB.

Dynamic Mechanical Analysis.

This strategy is the most delicate. It helps to gauge the temperature and stress-induced response of a material. Also, it helps measure different polymers' viscous and elastic components.

Thermal Mechanical Analysis

This technique is valuable in testing the polymers' coefficient of thermal expansion (CTE). However, it does not work so well on amorphous polymers. The reason is that the excessive heating of amorphous polymers is unpredictable.

Differential Scanning Calorimetry

This method is one of the most common. Generally, it involves comparing the supplied heat flow to the material for testing. Also, it draws reference from a similar material showing the transition points when heated to a certain level.

Factors Influencing the Cost of Tg130 PCB

Generally, printed circuit boards have properties that determine their cost, such as:

The type of material.

The material type largely influences the total cost of a printed circuit board. So, it is costlier for circuit boards made with tg130 PCB materials like glass-resin epoxy, a copper layer, and other significant parts.

Size

Also, the tg130 printed circuit board size determines the cost. It translates to the fact that more board space allows additional materials and more work.

Utilization of the working panel

Fully utilizing the working panel of your PCB ensures less cost. The product of the total quantity and the single unit area of the board divided by the functional panel space, all multiplied by 100, gives the effective panel utilization percentage.

The design

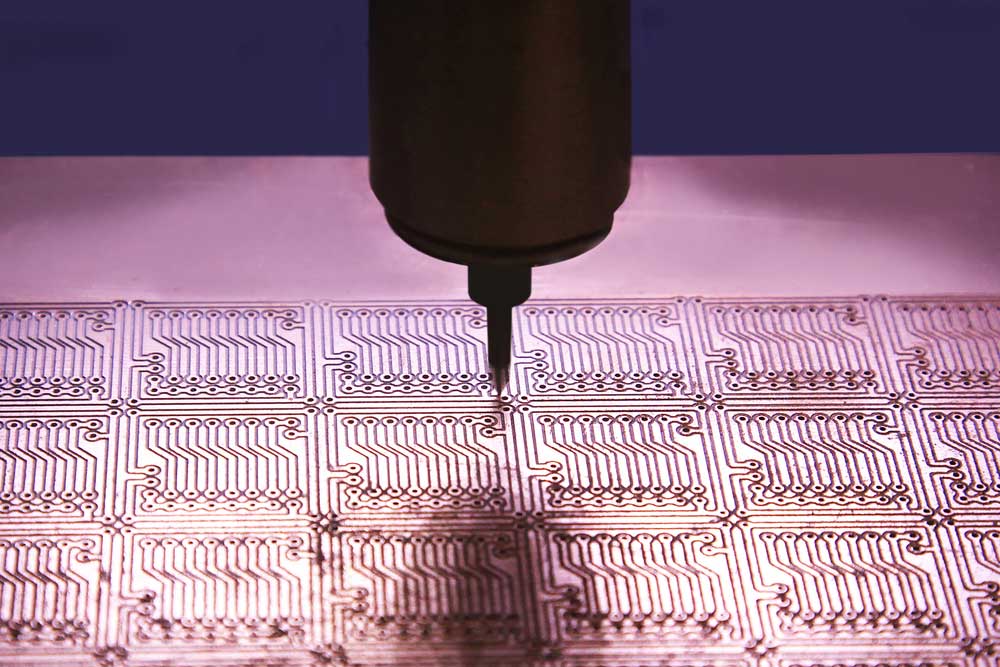

Different designs require different drill types. These, in turn, determine if you need a thicker board or not. Ultimately, your tg130 PCB design decides the assembling cost and, consequently, the price.

Hole size

Just like the PCB design, the hole size required determines the manufacturing cost. Smaller holes require more accurate precision than larger ones.

(A high-precision machine drilling holes in a PCB).

Delivery time

Finally, the cost of tg130 PCB relies significantly upon the indicated lead time. The cost of satisfying your needs adds to the overall expense as compensation.

FAQ about FR4 TG130

Which Solder Masks work best with FR4 Tg130?

The best solder masks help prevent oxidation that forms solder brides. So, solder masks should include red, green, yellow, purple, dark, blue, white, matte black, and matte green colors.

(A PCB engineer in the soldering process).

What Time is the Most Appropriate for the Use of FR4 Tg130?

The most appropriate time is one with a temperature that doesn't exceed 130 degrees Celsius.

Are there other Substitute FR4 Materials Asides from FR4 Tg130?

Yes, these include:

- FR4 Tg140 / Tg150 / Tg170 Materials.

- Halogen-free FR4 Tg150 Materials.

- Halogen-free FR4 Tg170 Materials.

What is the right thickness of the FR4 Tg130 Board?

FR4 TG130 boards are typically between 0.2 - 6mm thick.

Conclusion

In summary, the FR4 Tg130 is a flame-resistant printed circuit board. It saves the electronic components from overheating. While the maximum operating temperature (Tg) is 130°C, its remarkable insulation features remain beneficial in many thermal applications.

So do you need an FR4 TG130 or a similar PCB material? Whatever PCB needs you to have, contact us for a prompt response.

Special Offer: Get $100 off your order!

Please email [email protected] for details.