Computer-Aided Manufacturing (CAM) is a vital aspect of modern manufacturing, especially for PCB fabrication and assembly in the electronic industry.

And since the term has the word computer, it implies some level of automation in the manufacturing process.

But what is CAM exactly? And what are the required components for computer-aided manufacturing? Let's find out!

Contents

- What Is Computer-Aided Manufacturing?

- CAM vs. CAD

- Components Required for the Computer-Aided Manufacturing Process

- Responsibilities of Computer-Aided Manufacturing Software

- G-Code Post Processing

- G01 X1 Y1 F20 T01 S500

- Types of Computer-Aided Manufacturing Machines

- 3D Printers

- CNC Machines

- Electrical Discharge Machines

- Milling Machines

- Lathes

- Laser, Water, and Plasma Cutters

- Computer-Aided Manufacturing Applications

- CAM Advantages

- CAM Disadvantages

- Wrap Up

Special Offer: Get $100 off your order!

Please email [email protected] for details.

What Is Computer-Aided Manufacturing?

Computer-Aided Manufacturing (CAM) is a manufacturing process that uses computer systems and automated machinery to build products at high precision.

Traditionally, engineers manually set up the manufacturing process by creating patterns or jigs for the machines to follow.

However, automated machines use software to define the actions, paths, and procedures to follow.

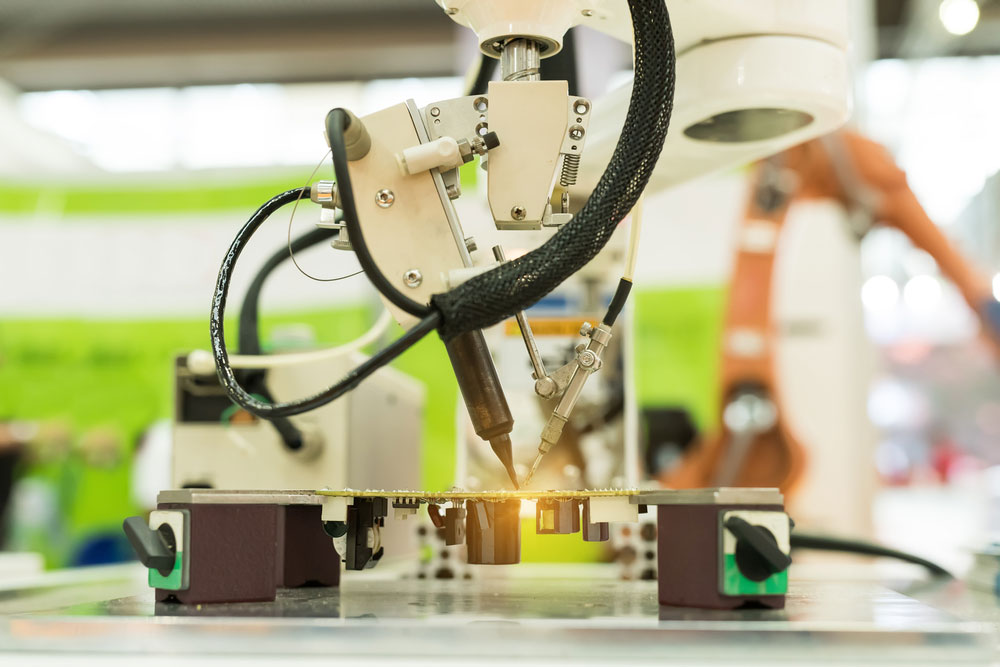

PCB processing on a CNC machine

CAM vs. CAD

Computer-Aided Design is the use of software to produce 3D designs to use in the manufacturing process. So product designers use CAD software to generate product blueprints, then send them to manufacturers for fabrication.

Manufacturers use CAM software to translate the designs and accompanying data into detailed instructions that drive the automated machines.

A concept showing how CAD software produces jet engine designs for CAM

Popular CAD software includes Autodesk Inventor, AutoCAD, Solid Works, and CATIA.

Components Required for the Computer-Aided Manufacturing Process

CAM systems consist of three components.

- Software: The software instructs the machine and guides the machining process by generating tool paths.

- Post Processing: Converts tool paths into a machine-understandable language.

- Machinery: Machines transform raw materials into finished products using instructions given by the software.

An up-close image of a milling machine cutting a circuit board

Responsibilities of Computer-Aided Manufacturing Software

CAD-CAM software allows manufacturing engineers to process customer CAD files to create a tool path for machining projects. Additionally, they perform simulations to help determine the machining cycle time. Other functions include the following.

- Recognizing the drilling data, artwork layers, and IPC netlist formats.

- Verify the order sequence of the layers.

- Translate electronic data into images to measure, view, edit, and check the designs.

- Configure the production panel nesting parts for optimal part orientation to increase efficiency and reduce material wastage.

- Conduct design rule checks to compare the IPC netlists with the imported design data.

- Creating solder masks, drill programs, silkscreen artworks, and other necessary tools for the machining process.

A machinist operates a machine from the G-Code monitor.

All these steps enable the software to reduce fabrication errors, complete projects smoothly, and reduce the turnaround time. And some popular CAM software includes Siemens NX, Work NC, Solid CAM, and Power MILL.

Special Offer: Get $100 off your order!

Please email [email protected] for details.

G-Code Post Processing

A crucial part of the CAM process is G-Code programming. After checking CAD software, running simulations, and optimizing the data, CAM software converts the data into G-code, a language that machines can understand.

G-Code gives instructions to control feed rate, speed, and other parameters, and a sample would look like the following.

G01 X1 Y1 F20 T01 S500

- G01 directs the machine to move linearly in the X1 and Y1 coordinates

- F20 is the feed rate (sets the distance the machine should cover in a single spindle revolution)

- T01 shows the tool number, one in this case

- S500 sets the spindle speed (500 rpm)

An abstract image showing how G-Code guides a CNC milling machine

G-Code commands are the masters of action and can include the tool length offset.

On the other hand, M-Code commands organize the functions by enabling you to control miscellaneous, non-geometry tasks like coolant on/off, rotation start/stop, pallet change, spindle rotation direction, etc.

Types of Computer-Aided Manufacturing Machines

CAM machines convert the designs into finished products and can include the following types.

3D Printers

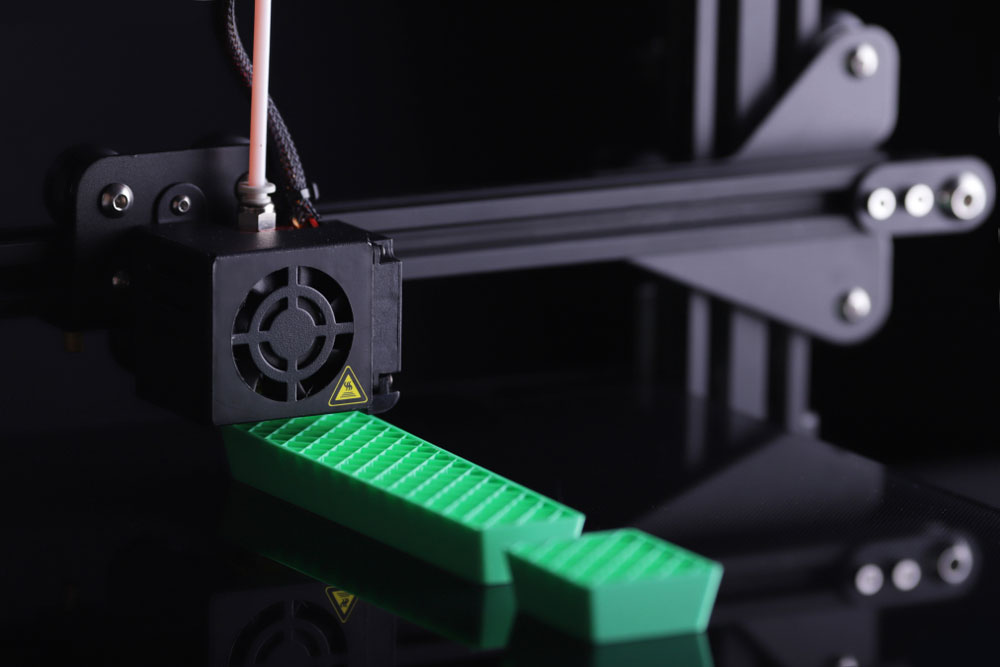

3D printing is an additive manufacturing process, and you can use CAM tools with this machine to build virtually anything in a layered production process.

A 3D printer prints an exclamation mark using green plastic.

CNC Machines

Computer Numerical Control machines fabricate components by carving and cutting to remove excess material using tools oscillating at high speed.

Circuit board processing on a CNC machine

Electrical Discharge Machines

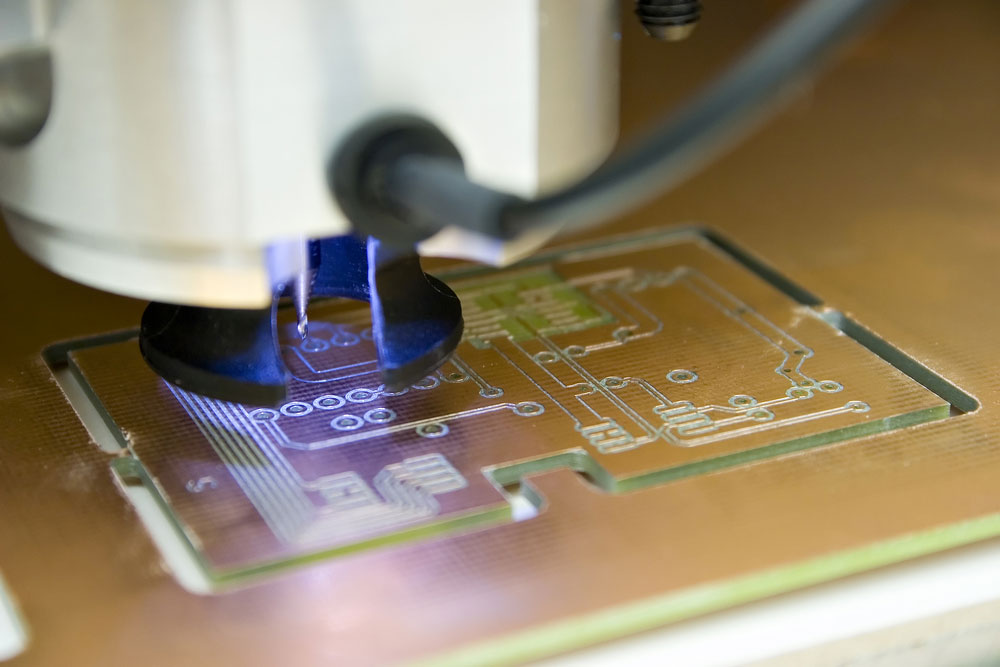

EDMs cut raw materials using electric discharge. The machines propagate electric sparks through raw materials that reach high temperatures and cut with ease. You can precisely control these sparks using CAM tools to cut through materials.

A close-up image of an electrical discharge machine at work

Milling Machines

Milling machining tools are the ideal workhorses for automated subtractive manufacturing. They can eliminate excess material from workpieces efficiently and accurately.

Lathes

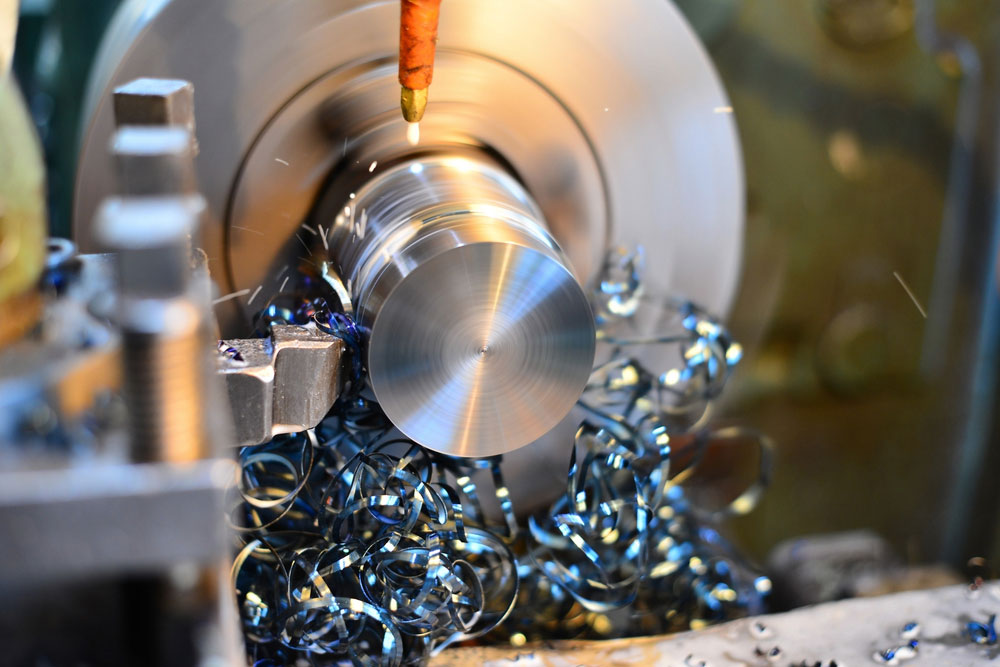

Lathes operate by spinning raw materials while chipping, carving, facing, chamfering, or knurling the sides to eliminate excess material using a stationary tool.

A lathe grinding machine in action

Laser, Water, and Plasma Cutters

These CAM machines use precise lasers, high-pressure water jets, or plasma torches to slice extra materials from the final product based on the designs.

A high-pressure water-jet cutting machine

Computer-Aided Manufacturing Applications

- PCB manufacturing

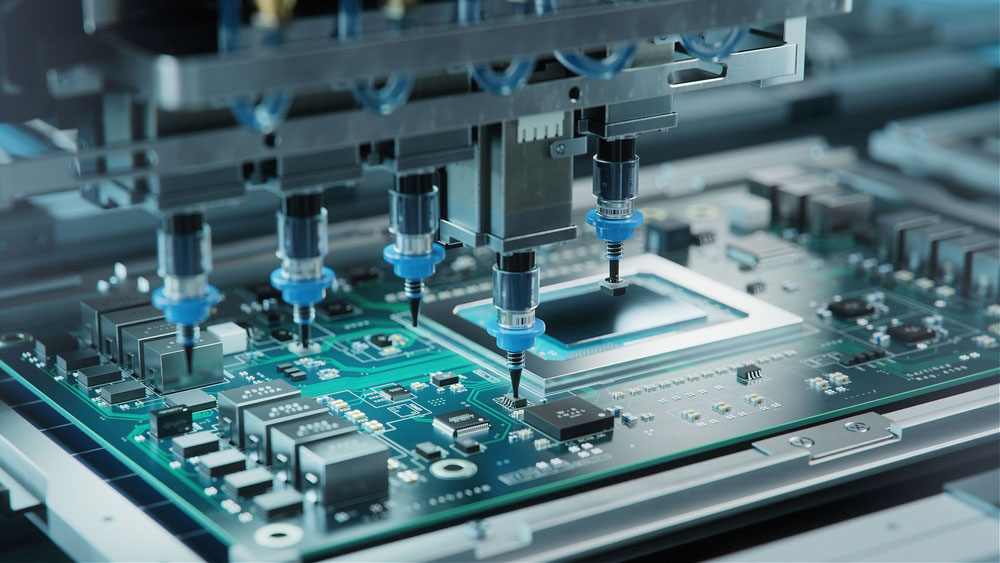

- PCB assembly (picking and placing)

- Textiles

- Military (sub-marine applications)

- Astronomy and aerospace (precise telescope mirror machining and etching)

An automated pick-and-place machine for PCB assembly

CAM Advantages

- High accuracy, consistency, and predictability

- Versatile and flexible due to the multi-function, multi-axis machining

- Automates the creation of performance reports

- Increases productivity

- Reduces material wastage

- Integrates with various processes and systems in the manufacturing process

- Creates a visual representation of the production process

- Integrates testing and modeling applications

- Can optimize CNC programs

- Enable quick and cheap prototype creation

- Improves client accessibility (manufacturers can import client engineering design files)

- Scalable modern CAM solutions

CAM Disadvantages

- Although rare, computer errors can occur.

- CAM is impossible without CAD, and the software for both processes is costly

- Computers, machinery, controllers, and other pieces of hardware are expensive.

- Machinist/manufacturing engineer training is not cheap.

Wrap Up

In conclusion, Computer-Aided Manufacturing is crucial for precise and efficient manufacturing. And these factors are critical for fabricating and assembling modern-day electronics. So PCB manufacturers must use this automated manufacturing process to build circuits for your project. And we utilize it at OurPCB. So you can expect high-quality circuit boards from our facility. Contact us and send your design files today, and we'll have our trained engineers handle the CAM process until you get the final product.

Special Offer: Get $100 off your order!

Please email [email protected] for details.