Getting a new or modified product to market might have higher than expected costs if you fail to factor in all the expenses. And the same case applies to electronic devices with PCBs. Besides the item's production cost, there is the NRE cost of setting up the manufacturing environment to build the product. We will look at this NRE charge and how it factors into PCB production in detail below. Read on to learn more!

Contents

- What is an NRE Charge?

- What is an NRE Charge For

- Tooling

- Programming

- What is an NRE Charge Not For

- When To Use NRE

- NRE Steps

- System Definition

- Design and Development

- Platform Design

- Factors Affecting the NRE Charge

- Multiple Orders from a Single Company

- Increased Ordered Quantities

- Number of Physical Dimensions and Layers

- How To Pay Non-Recurring Engineering Charges

- Breakout

- Amortize

- Can Manufacturers Waive Non-Recurring Engineering Costs?

- What If I Paid The Non-Recurring Engineering Costs and It Doesn't Come Out Okay?

- Wrap Up

Special Offer: Get $100 off your order!

Please email [email protected] for details.

What is an NRE Charge?

An NRE (Non-Recurring Engineering) charge is a one-time cost to cover the design, development, and testing of a new product or enhance an existing one. In a nutshell, the fee includes all the up-front charges incurred when manufacturing the product, and it is inevitable during PCB manufacturing.

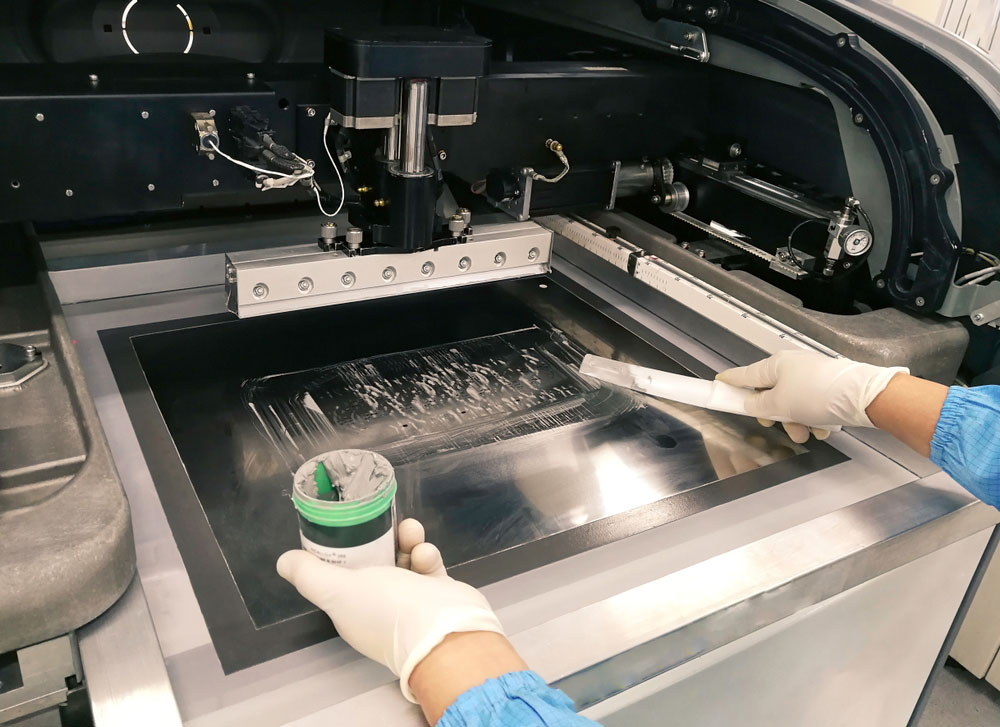

A worker applying solder paste on a stencil for PCB production

Usually, it includes the following.

- Labor costs

- Prototype materials

- Product testing

- Pre-production activities

- Electronics and software development

What is an NRE Charge For

This engineering cost falls into two primary categories.

Tooling

Non-recurring engineering tooling costs are the costs of acquiring tools like stencils, metal, fixtures, etc. This cost can be high and complicated because you need custom-made parts built for a particular product and customer.

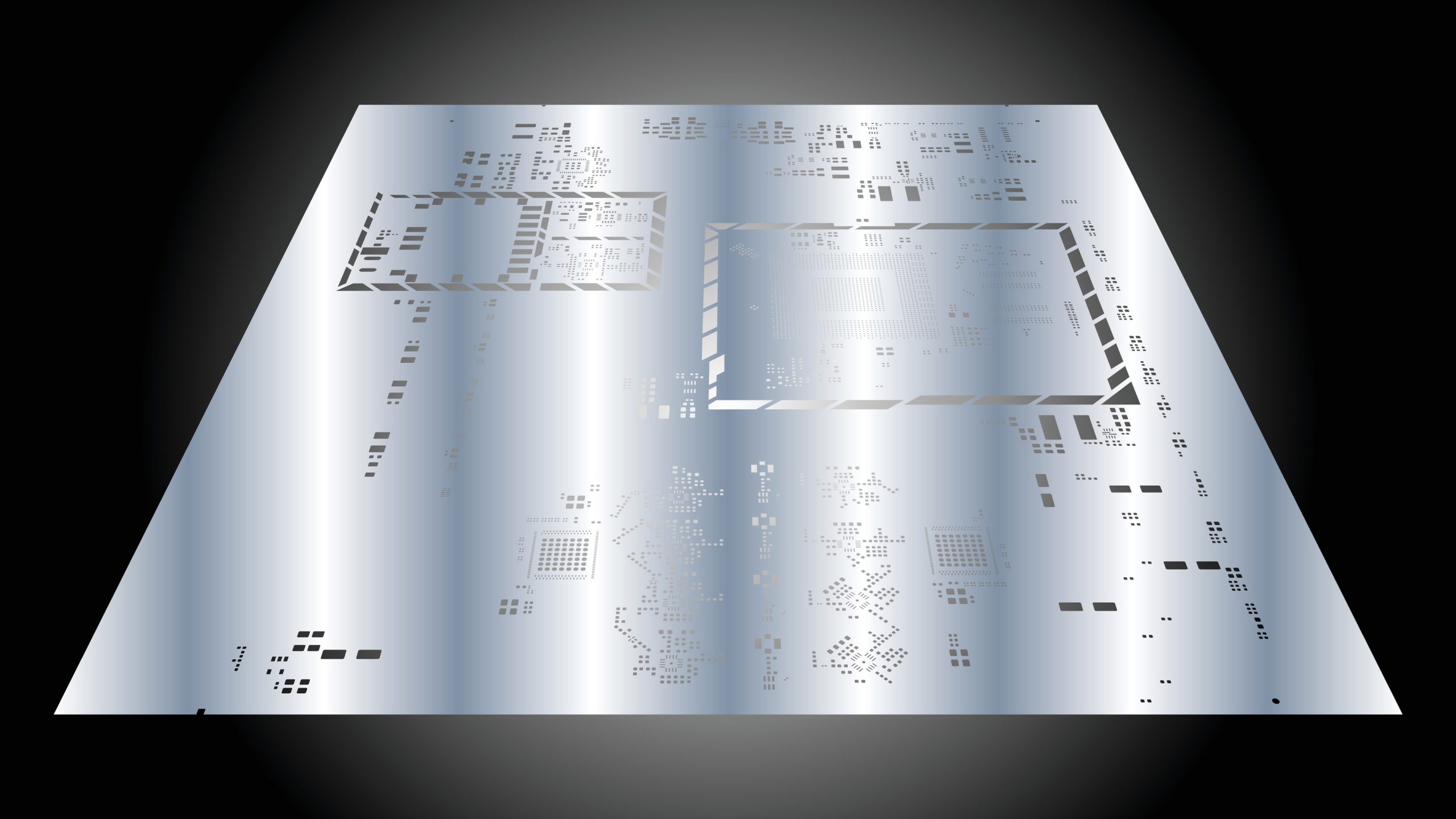

An opening solder stencil metal mask

One example is the solder stencil, which is like a fingerprint. It is specific to a single PCB design and requires a high cost to build. But once done, you won't need new stencils for fabrication.

Programming

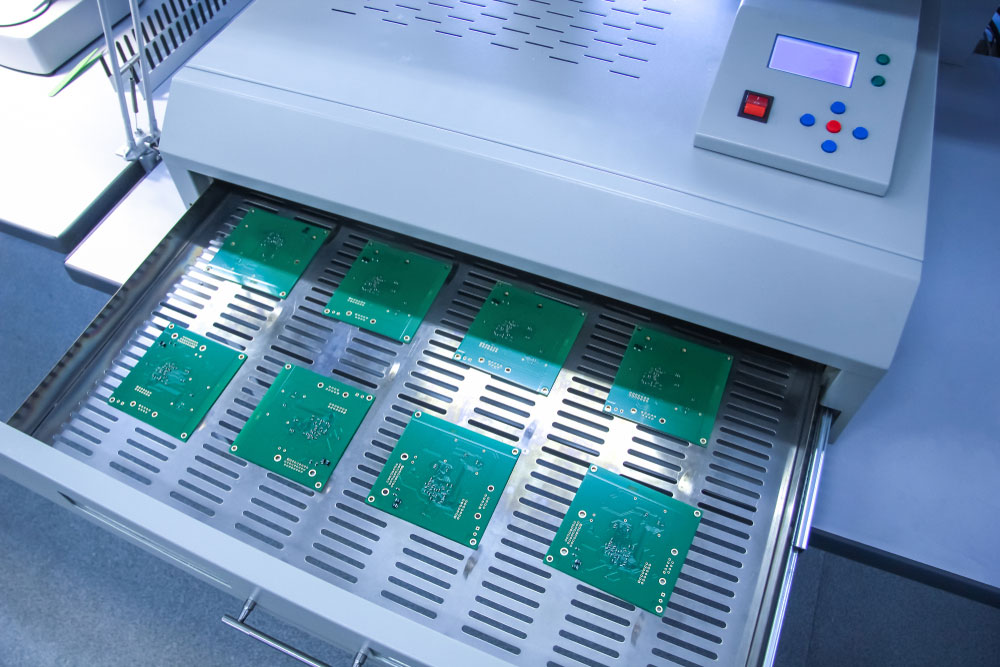

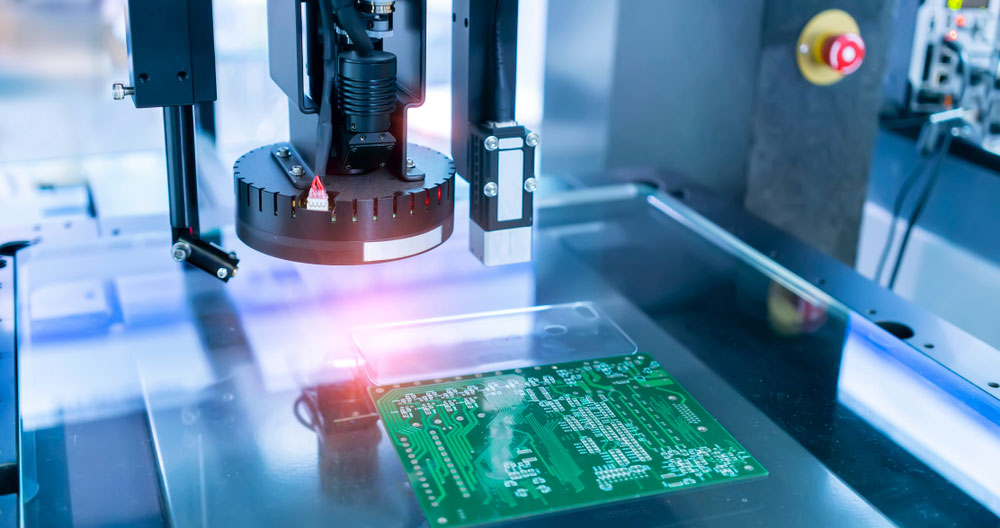

The setup or programming cost implies the charges incurred when programming every machine involved in the production process. It takes labor and time to set up the pick-and-place, reflow oven, selective solder, and inspection machines, and these factors add to the production cost. The programming charge can be a one-off cost unless a product design revision occurs.

An automatic pick-and-place machine

What is an NRE Charge Not For

Non-recurring engineering costs can take up a significant chunk of your project's budget. So you should know what to pay for and not to pay for to keep the expenses low. These non-recurring costs are not for the following.

- Off-the-shelf products or items sold to several clients by the supplier

- Standard components for market applications and larger product portfolios

The manufacturer should cater to the R&D and design costs in such cases.

When To Use NRE

You can use non-recurring engineering charges when:

- You need additional features or functions on a PCB

- A new product performs differently compared to other finished products from the same manufacturer

- Fabricators halt supporting customer needs by upgrading to a new product and using the new model

Special Offer: Get $100 off your order!

Please email [email protected] for details.

NRE Steps

The NRE process involves the following steps.

System Definition

This stage defines the functions and performance of the product prototype. Additionally, it determines the product specifications.

Design and Development

The product design stage also defines the technology roadmap to follow to the last phase of new product development.

A soldering oven (require programming before setting up for a new project)

Platform Design

This step defines the following elements.

- Customer's review of the project plan and statement of works

- Finished specifications design and review

A fabricator can only manufacture the board after you approve the designs and specifications.

Factors Affecting the NRE Charge

These factors significantly impact the non-recurring engineering charges and can help you reduce these costs.

Multiple Orders from a Single Company

Research first to find manufacturers who give NRE charge discounts before placing any PCB fabrication order. And you must pay the entire NRE costs on the initial orders. But the manufacturer should offer NRE charge discounts after a few orders. You will advance from being a new customer to a genuine client who qualifies for these offers. Also, there will be fewer chances of deception from both parties due to the developed trust.

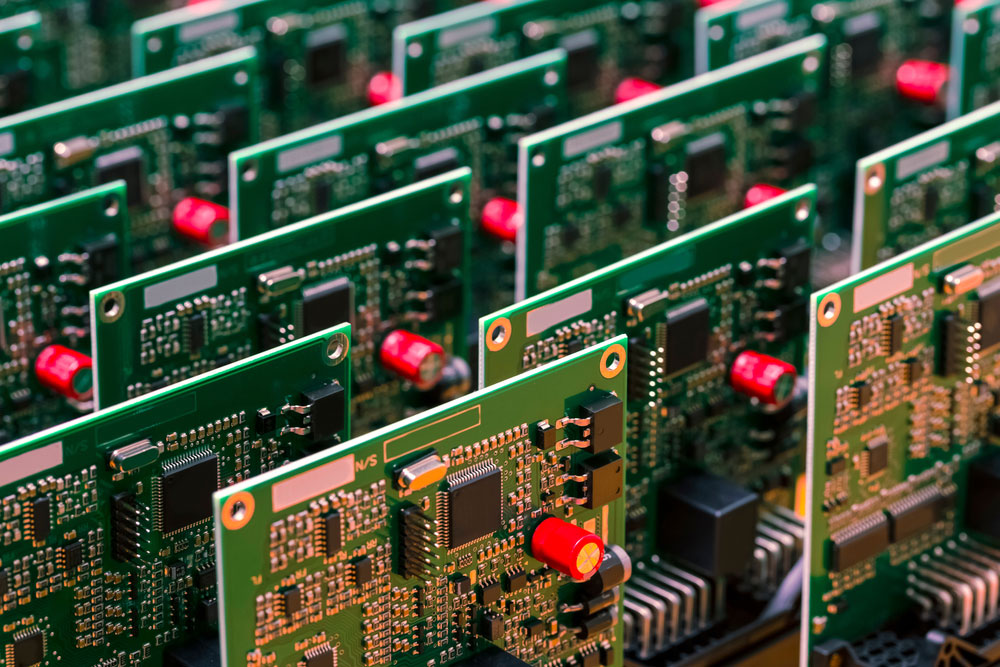

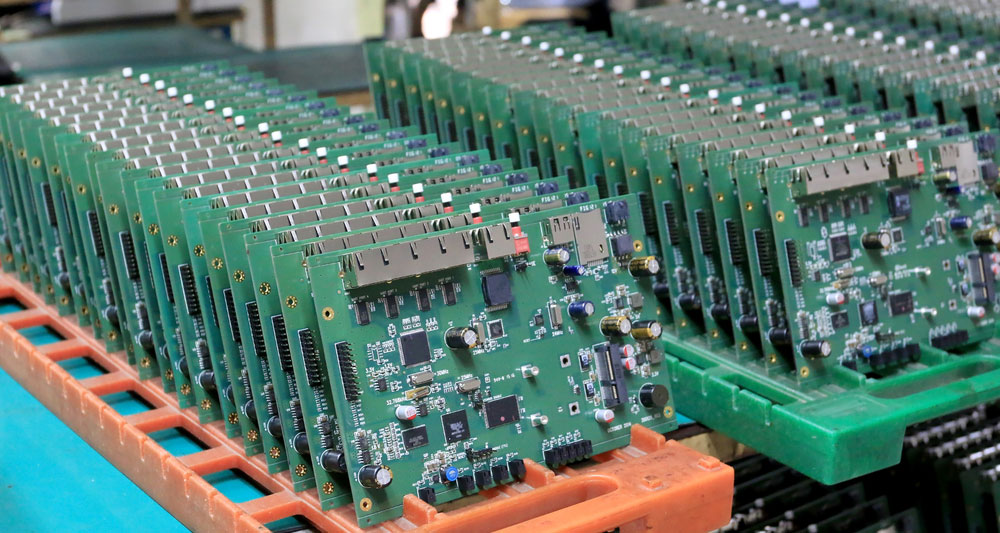

Multiple printed circuit boards in production

More importantly, some fabricators keep the stencils and programming files for your PCB projects. So you will get substantial offers due to the reduced programming and tooling costs.

Increased Ordered Quantities

The unit cost for each circuit board will be significantly higher if you place an order with few pieces than one with multiple orders. With few products, the NRE charges will be a significant portion of the budget.

Multiple printed circuit boards after manufacturing and assembly

Also, consider penalizing multiple projects. Individually placing two orders will incur separate NRE charges. However, if you order two different projects as one, you will pay a single NRE charge. That is the cost-saving idea behind panelization.

Number of Physical Dimensions and Layers

Creating more layers and test beds for circuit boards or having broader dimensions increase the material and effort used. So these factors will increase the NRE cost. You can minimize these costs by designing small PCBs with few layers. Only use multiple layers if required.

Other factors include the following:

- Type of technology

- Product design's complexity

- Required skills

- Packaging type

- Special procedures required

- Quantity of work

How To Pay Non-Recurring Engineering Charges

There are two ways to pay for the non-recurring engineering charge.

Breakout

Breakout payment involves making upfront payments for the NRE. For instance, the fabricator can charge $60 per item if the unit cost is $50 and the NRE charge is $10. So the price per unit will drop to $50 after paying the NRE fee.

A visual inspection machine programmed to check a specific circuit board

Amortize

Amortize implies you pay the NRE in increments by adding this one-time fee to the unit cost. It is challenging to monitor amortized costs, so most people prefer the breakout payment method.

Can Manufacturers Waive Non-Recurring Engineering Costs?

No. Unlike off-the-shelf products, manufacturers require production and engineering resources to build or upgrade your product. So it is impossible to waive these costs. However, there are a few exceptions.

For instance, if the customer account or order is large enough and gives the manufacturer a good profit. This margin makes the NRE insignificant, and the manufacturer can waive it.

Also, you can get a waiver if there are manufacturing issues and the tooling requires repurchasing or repeated programming to fix the matter.

Lastly, the fabricators can waive the fees if they have forged a strong relationship with the customer over time.

What If I Paid The Non-Recurring Engineering Costs and It Doesn't Come Out Okay?

First, check for inconsistencies in your designs and documentation. If you spot any manufacturing issues (in tooling or programming), the fabricator needs to redo them to fix the matter. The contract signed between yourself and the manufacturer should define who owns the risk and will bear this cost.

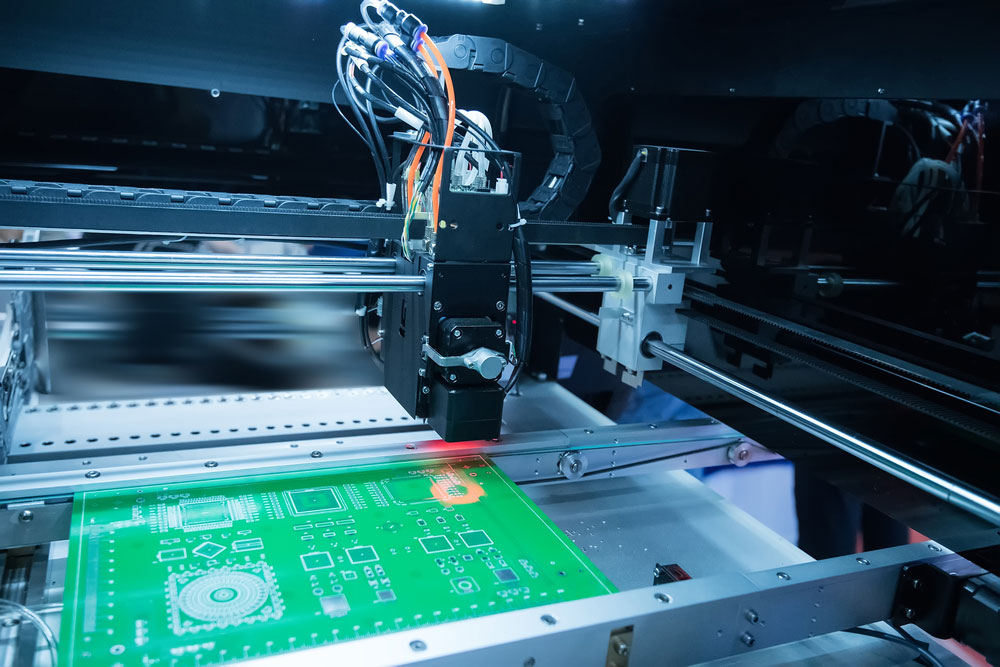

PCB processing on a CNC machine

Some fabricators cannot guarantee the successful building and delivery of each product feature, especially with new technology. So you might have to hear the risk.

Wrap Up

In conclusion, non-recurring engineering costs are essential in producing new or modified PCBs. So you need to plan and budget for this one-time cost if you want a circuit board for your project. And you can get discounts if you make multiple or high-order quantities with OurPCB. Contact us today to get a free quote on your PCB designs before we get started on your product.

Special Offer: Get $100 off your order!

Please email [email protected] for details.