Since their invention in the 50s, drag chain cables have been an essential part of tools that require external cables or hoses. These include large machines for field operations to small ones like 3D printers and medical/lab equipment. We will examine these cable chains closely to explain their functions and build quality. Let's get right into it!

Contents

- What Are Drag Chain Cables?

- Cable Carrier Assembly Structure

- Functions of Drag Chain Cables

- Keep Electrical Cables or Hoses in a Constrained Space

- Protect the Hoses

- Provide a Safe Bend Radius and Strain Relief

- Hose/Cable Neat Arrangement

- Improve Operator Safety

- Materials Used To Make Drag Chain Cables

- Steel/Metal Cable Carriers

- High-Performance Plastic Cable Carriers

- Types of Cables Used in Cable Carriers

- Energy Chain Variants

- Applications of Cable Carriers

- Conclusion

Special Offer: Get $100 off your order!

Please email [email protected] for details.

What Are Drag Chain Cables?

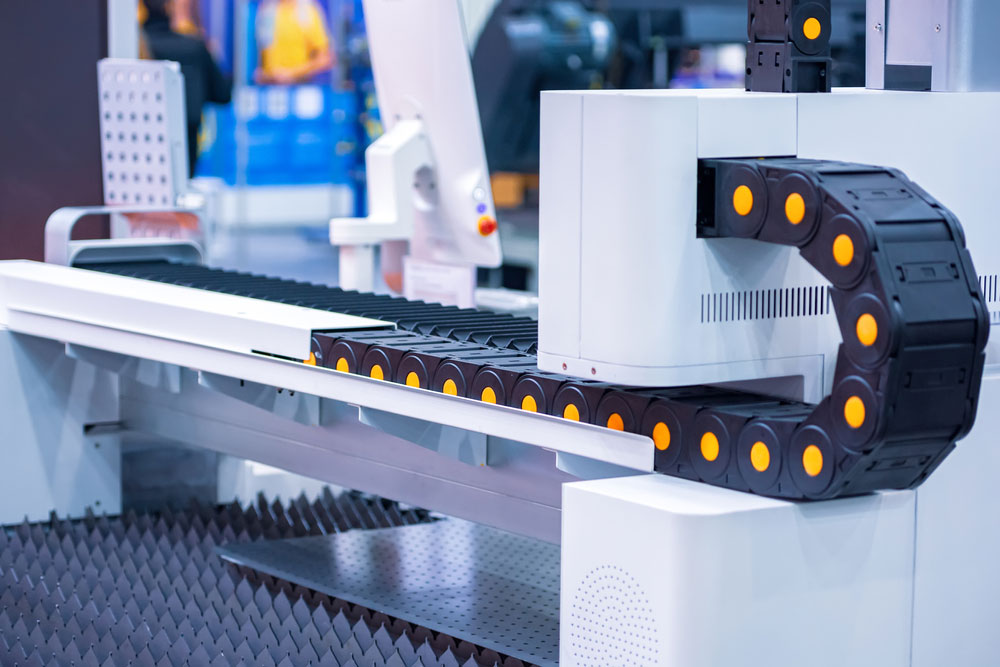

Also known as cable chains, cable carriers, or energy chains, drag chain cables are hollow flexible structures used to guide hydraulic & pneumatic hoses or electrical cables when in motion.

A plastic cable chain

The cables or hoses fit inside the hollow cavity in the carrier, allowing the surrounding structure to protect, guide, and support them to prevent damage or accidents. You can arrange cable drag chains to handle rotary, vertical, horizontal, or 3D movements.

Cable Carrier Assembly Structure

Most cable chains feature a rectangular cross-section with a similar-shaped cavity lengthwise. The units usually have cross bars along their length that you can open to insert the cables/hoses or connect plugs. Inside, the carrier features separators to hold the cables/hoses neatly. Also, you can use the integrated strain relief in the hollow structure to secure the contents. Chain end brackets help mount the carrier to the machine.

A CNC drag chain cable with electrical wires inside

On the exterior, the chains have a rigid jointed structure that permits bending in one plane or direction. And the carrier ends offer rigid mounting, as well. This combination keeps the cables or hoses from tangling, crushing, or flopping in the wrong direction.

Functions of Drag Chain Cables

Cable drag chains have the following five primary functions.

Keep Electrical Cables or Hoses in a Constrained Space

The boxed housing of the cable drag chain will never exceed its volume despite moving in the X, Y, or Z axis. So you can be sure anything you design around the chain will not collide with the hoses or electrical cables.

A drag chain cable for an inkjet printer

Protect the Hoses

In outdoor applications, a cable guide can protect hydraulic and pneumatic hoses from the elements, UV radiation, and chemicals. Such guides usually have a closed or sealed design.

Provide a Safe Bend Radius and Strain Relief

Electrical cables and hoses can break if bent continuously under a small radius. Cable chains offer strain relief to prevent premature failure. They do this by providing the minimum bending radius.

A flexible cable carrier

Hose/Cable Neat Arrangement

Not only do energy chain systems keep the cables organized neatly in one package, but they also prevent the individual cables from tangling with each other.

Improve Operator Safety

The electricity in the wires or fluid in the hoses might be dangerous and harm the operator if exposed. Drag chains safeguard operators by protecting the cables from entangling and possibly snapping. And they protect the machines from damage, as well.

Special Offer: Get $100 off your order!

Please email [email protected] for details.

Materials Used To Make Drag Chain Cables

Flexible drag chain cables can be plastic or steel-made to match the requirements or application restrictions. The two materials have different characteristics that make them suitable for specific applications.

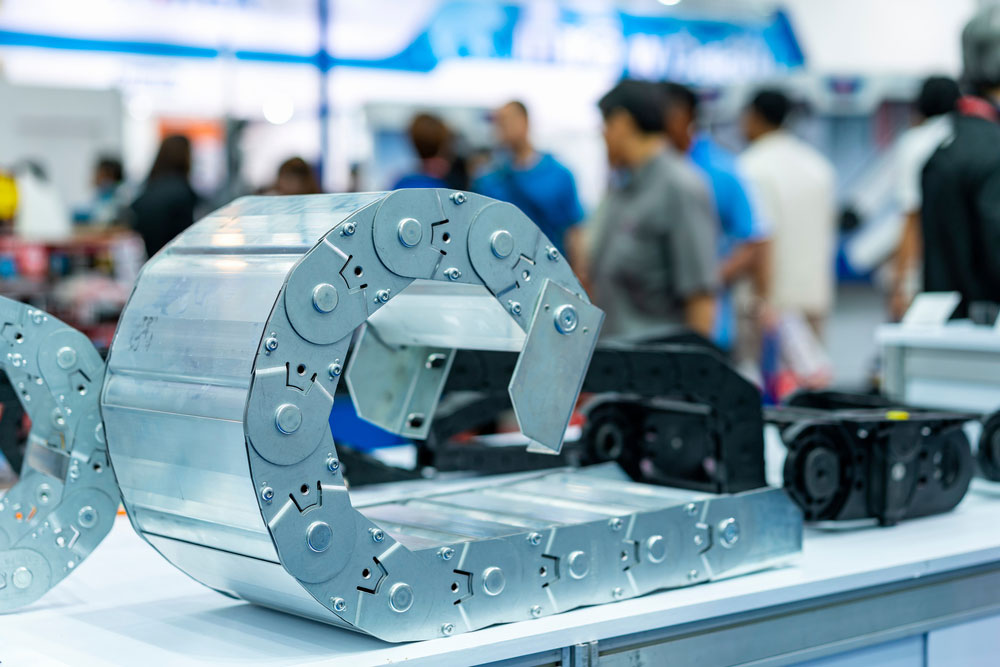

Steel/Metal Cable Carriers

Steel is the material of choice for making cable carriers for industrial applications due to its temperature resistance and high tensile strength. The typical steel types used in drag chains include the following.

A flexible metallic industrial drag chain cable

- Stainless steel: This material offers incredible environmental resistance plus a heavy load-carrying capacity.

- Zinc-plated steel: Ideal for traditional high load-carrying capacity applications.

- Hybrid (metallic & nylon) steel: This steel is suitable for applications requiring flexibility, acceleration, and high speeds.

High-Performance Plastic Cable Carriers

Plastic energy chains began appearing in the market in the early 70s and are now as prevalent as their steel counterparts. Specialized high-performance plastics have become typical for making these devices because of the following properties.

- Chip repelling: These specialized plastics safeguard against flying metal chips that reach 1,500°F (816°C).

- Dust and debris free: Some plastics don't create dust or debris, which makes them ideal for holding cables in cleanrooms. These super-clean environments are typical in semiconductor manufacturing.

A semiconductor production fab cleanroom

- Electrostatic discharging: Manufacturing static-sensitive electronics requires electrostatic discharging plastics.

- Flame retardant: Ideal for manufacturing environments with combustible materials.

- Magnetic: Plastics are non-magnetic, but some specialized materials have magnetically detectable fragments. Such plastics are suitable for food processing operations or other applications requiring minimal product contamination.

Types of Cables Used in Cable Carriers

Cable carriers support, guide, and protect several flexible cables, including the following.

- Data cables: These wires are ideal for operating between -40 to 70°C

- Microbial-resistant and bio-oil cables: These environmentally-friendly cables have a recyclable material construction and are resistant to biofuels & abrasion.

A cable chain carrier for an inkjet machine

- Polyurethane (PUR) cables: PUR cables come in two types. The flexible material type has a -20 to 80°C operating range, while the fixed type extends the temperature range on both sides to reach -40°C and 80°C.

- Polyvinyl Chloride (PVC) cables: PVC is a pliable material, so these cables are flexible. Additionally, they feature number coding with meter marking and reliable oil resistance. PVC cables have a -10°C and 80°C temperature operating range.

Energy Chain Variants

Modern cable carriers come in several variants with different sizes, styles, performance ranges, and prices. These variants include the following.

- Open

- Closed (for dirt and debris protection)

- Stainless steel (or steel)

- Low noise

- Multi-axis movement chain

- Cleanroom (minimal wear) compliant

- Temperature, water, and chemical resistant

- High load resistant

A drag chain cable for a cutting machine

Applications of Cable Carriers

Cable carriers are ideal for any application that requires moving automation that involves transferring data, energy, gases, or liquids. These include the following.

- Machine tools

- Port cranes

- Car washes

- Forklifts

- Medical and lab equipment

- 3D printing machines

- Offshore oil rigs

- Industrial robots

You can group them into these two functional units.

- Rotary/Circular: As the name suggests, these move in circular arcs

- Linear: These move in straight lines for lengths less than a meter to over 100 meters

- Also, you can classify them by application into the following categories.

- Standard: These chains have a simple design to allow quick cable installation.

- Advanced: Feature variable chain widths with multiple separation options.

- Extreme: These steel or stainless steel carriers are ideal for harsh environments.

A machine’s industrial metal flexible drag chain cable

- 3D application carriers: These chains feature swivel and rotational movement types to cover three dimensions.

Conclusion

To summarize, cable drag chains are vital in machinery with external cabling or electrical/data wiring due to the benefits (functions) explained above. And they are primarily metallic or plastic-built to suit different applications. If you have any questions or comments, contact us, and we'll be in touch asap.

Special Offer: Get $100 off your order!

Please email [email protected] for details.