Are you looking for a company that can provide you with the best Fast Print PCB products? Do you need someone to increase the value of the product significantly during the assembly process? Do you need time to participate in the layout review? This article serves as a guide to help you make informed decisions and achieve the desired results.

Special Offer: $1 for 5 PCB Assemblies!

Please email [email protected] for details.

1、What is a Fast Print PCB?

Image 1: Fast Print PCB

Image 1: Fast Print PCB

Fast Print PCB is different from traditional fabrication in terms of the steps involved. There are several steps simultaneously done by teams or machines. It means saving time and reducing the probability of errors to zero. All the necessary aspects and processes are put in place beforehand.

2、Fast Print PCB Classification

Image 2: Fast Print PCB Classification

Image 2: Fast Print PCB Classification

Pattern classes and drill classes are used as shorthand terms to measure the manufacturability of the PCB. Why so? It controls whether the circuit board may incorporate it. It has an impact on the amount you pay. It has an impact on the amount you pay. The smallest production tool size on the board is what determines the drill class.

Special Offer: $1 for 5 PCB Assemblies!

Please email [email protected] for details.

3、Factors Affecting the Quality of Fast Printing PCBs

Image 3: fast printing PCBs

Image 3: fast printing PCBs

Fast Print PCB inspection is a crucial task that must be done excellently before forwarding them to the production phase. Once at the production stage, several steps are involved, and testing in each step is mandatory to filter out any error. It means that a lot of time is spent coming up with a high-quality PCB. Time means money, which is true in the industrial sector; the quicker your production time, the better because you will produce more within a lesser time.

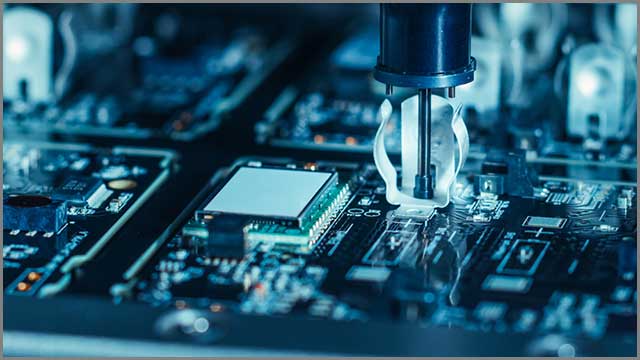

Image 4: Fast Print PCB

Image 4: Fast Print PCB

4、Factors to Consider in Fast Printing PCB Design

Image 5: Fast Print PCB

Image 5: Fast Print PCB

There are specific guidelines that see that only the best practices are adhered to in Fast Print PCB Design. It will reduce the board's cost and ensure that the error generated in the manufacturing process is maintained at a minimum level.

It is not an easy feat to create a high-quality Fast Print PCB design. We must consider the different elements.

4.1 Board Materials

It is the foundation of everything in the design process. It is essential to understand the materials that will use. There is a need to use a non-conductive and solid material, and the best is laminated copper. The material at the base is FR-4, glass-reinforced epoxy. Copper provides a conductive surface while FR-4 is flame resistant. In the case of high-performance circuits, ceramic or PTFE bases will do.

4.2 The Fast Print PCB Stack-up

It is the number of layers that will be present in each Fast Print PCB. It helps the engineer understand the impedance each layer will require to make the correct decision concerning the fabrication to allow the desired reliability and yield. It will also help in minimizing the production cost.

4.3 Copper Traces

These are the most vital elements on the Fast Print PCB and are created by getting copper from the base material. It is essential to understand their properties and limitations during the design process.

4.4 Vias

The work of vias is to establish connections between different components in the Fast Print PCB. The best fast printed PCB design is to minimize vias. There are different types of vias:

● Buried

● Through

● Blind

● Stacked layer

● Multi-layer

● Single-layer

4.5 Selection of Parts

It is essential to select parts that are widely available and can be accessed easily. If something is no longer in production, don't use it. It would help if you also were wary of parts sold in huge numbers because you might be forced to get an enormous amount that you do not need. All parts come in the form of a package.

4.6 Signal and Power Integrity

There is a need to check the times of signal fall and rise, the drive strength, impedance, and track lengths. All these to ensure quality performance.

5、Fast Print PCB Data Input Requirements

Image 6: Fast Print PCB

Image 6: Fast Print PCB

Fast Print PCB in the data input must meet several requirements. The acceptable data format for PCB layout has two main branches:

artwork and drill holes. The artwork has to do with all types of layers, for instance, copper, legend, and solder mask. There are also peel off layers, SMD pastes layers, and carbon layers, not forgetting mechanical layers. All Gerber specifications, dynamic process format, and CAD data are acceptable in terms of artwork.

In terms of drilling, some manufacturers will require only ASCII-encoded files because they are easy to read. What else is needed?

• Gerber format true drill data

• DPF(dynamic process format) true drill data

• Excellent 1 or 2 and an appropriate tool list that is appropriately embedded

• Sieb & Meyer and an appropriate tool list also appropriately embedded

We have already looked at two of the preferred data formats:

Extended Gerber X2 for artwork and Excellon 1 and an appropriate tool list embedded accordingly for drilling. Automated analysis and visualization also require a PCB visualizer. This visualizer works only with specifics such as mentioned above.

You should only provide the PCB manufacturer with the data files needed for production. One of these data files is the Gerber files, which work with several layers like SMD paste, copper, solder mask, mechanical, peel-off and via-fill, and carbon.

Excellent, as mentioned before, works well when it comes to drilling. If you would like something different like an array biscuit or matrix from one board data, you can supply your manufacturer with a DPF(dynamic process format) file or Gerber file.

It is easy, so make sure your file system has an easy-to-call name. Avoid long names. The best way to name a file is to match the name with the functionality. There should be information about the layer function. The data should not be scaled.

The Gerber files you supply should not contain zero size apertures, and the same is true for the Excellon data. It is either you are using a similar offset for the Gerber layers and the Excellon drill data or use no offset at all. Deal with the same units in all output files so that you do away with errors due to converting or rounding off.

The data supplied should be as seen from top to bottom through the PCB. It is the accepted universal practice. So what does this mean? It means that when you are looking at the Gerber data, the text on the top side of the board should be readable white text on the bottom should be non-readable. To minimize or eliminate mirroring errors, make sure the copper layer contains some small text. This text could be the company name or the board identification.

Use flashed pads for the Gerber files. The CAD PCB design software should have an aperture list to ensure the output reveals the apertures included in the design. All layers must come with the board outline to enable your manufacturer to align all layers properly.

6、Conclusion

Therefore, to obtain high-quality fast-printing PCBs, you must find a professional supplier with extensive experience and professional materials and machines.

At OurPCB, we ensure that excellence is the epitome of all our operations. We specialize in Fast Print PCB production, among other PCB related services. For the last ten years, we have been in the business of providing a wide array of clients with critical and high-performance PCB and PCBA solutions.

Special Offer: $1 for 5 PCB Assemblies!

Please email [email protected] for details.