Printed circuit boards play an integral part in almost all electrical devices that we use today. These circuit boards have to withstand the rigors of several operational environments. For this reason, these circuit boards get coated with several types of surface finishes.

For instance, a copper layer surface on PCBs tends to oxidize when into contact with air. Surface finishes are essential since they help towards the reduction of oxidation and contribute to electrical performance and solderability.

While several types of surface finishes are available, this post concentrates on one crucial variant – 13 advantages Electroless Nickel Immersion or ENIG plating or immersion gold PCB finish.

(An ENIG plating on a PCB that finds use in day to day life)

Special Offer: $1 for 5 PCB Assemblies!

Please email [email protected] for details.

1.Easy to Process Structure

There are plenty of benefits that are associated with ENIG. However, one of the most significant advantages of this type of printed circuit board surface finish is that it is a natural process mechanism to undertake.

Many printed circuit board designers prefer ENIG plating as opposed to Hot Air Solder Leveling or HASL finish or even Nickel Palladium (ENEPIG) based on the fact that HASL is one of the most straightforward processes or finishes to undertake.

For instance, matters to do with solderability are essential when working with printed circuit boards. Specific finishes such as ENEPIG and OSP (Organic Solderability Preservative) have previously proved difficult when it comes to soldering them. However, such is not the case for PCB immersion gold finishes.

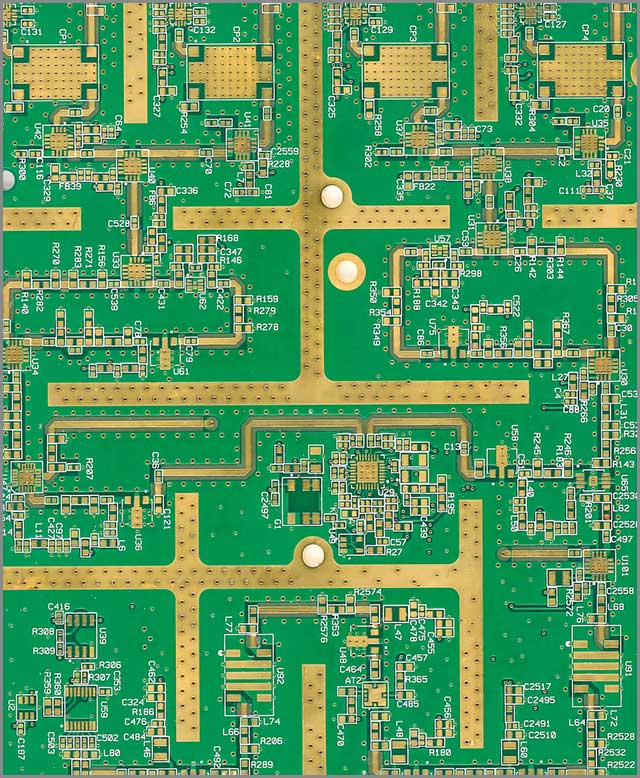

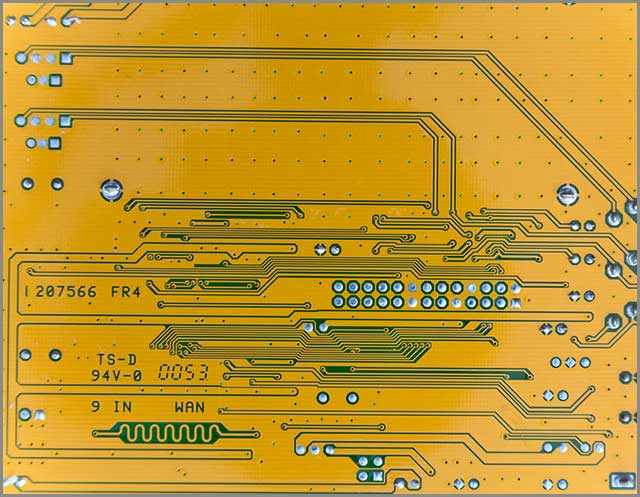

(It is easy to structure ENIG plating on a PCB even though it is somewhat engaging)

2.Flat Surface

ENIG plating is lately turning out and becoming a popular surface finish preferred by many PCB manufacturers. ENIG consists of a double layer metallic coating consisting of nickel that acts both as a surface and a barrier to which designers can solder the components.

It comes in as an ideal answer to the latest industry trends, such as the rise of complicated surface components and lead-free requirements that demand flat surfaces, such as BGAs and flip chips. Again, the ability to perfectly fit into flat surfaces is another advantage associated with ENIG.

(The designer checks the ENIG coating on the flat PCB to ensure proper surface)

3.Good oxidation Resistance

Experienced and high-quality printed circuit board manufacturers in the market for PCB surface finishes always look for surface finishes resistant to oxidation. Another significant advantage associated with ENIG surface finish is that such a finish offers excellent oxidation resistance, unlike other surface finishes such as HASL or Nickel Palladium (ENEPIG).

ENIG surface plating consists of an electroless nickel plating covered with thin layers of immersion gold that protect the nickel from any oxidation. With few chances of oxidation ever occurring, ENIG finishes ensuring that a printed circuit board is corrosion resistant in addition to assuring it of extended shelf life.

(ENIG surface plating protects the nickel from any oxidation)

4.Good electrical performance

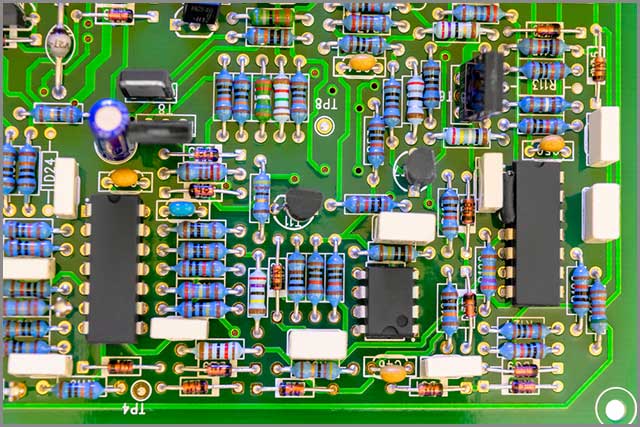

When manufacturing printed circuit boards, every detail matters. The entire placement of wires, finishing touches, and the board's overall design come together towards the manufacture of a printed circuit board that functions as required.

When it comes to surface finishing, immersion gold or ENIG surfaces are the preferred choices because they offer excellent electrical performance, unlike other surface finishes such as HASL or ENEPIG. Without a doubt, ENIG is now one of the most widely used finish across the PCB industry because it offers outstanding electrical performance in between all the components of a PCB.

(PCBs that undergo the immersion gold processes have better electrical performance)

5.High-temperature Resistance

A majority of printed circuit boards, especially those that find use in military and medical applications get, are subjected to high-temperate conditions. Unfortunately, when it comes to where such printed circuit boards find much use, plenty of printed circuit board designers find it hard deciding the type of finish to use.

Plenty of them –especially those new to PCB design- find it hard to choose the right kind of finish to use, especially when it comes to HASL vs. ENIG. Nevertheless, all is not lost. As a designer, it is advisable to use ENIG finish based on the fact that it can effectively withstand high temperate conditions without affecting your PCB's functionality. An ENIG finish is temperature-resistant and comes with excellent thermal diffusion properties that are excellent for your PCBs.

(Some finishing are abysmal when it comes to high temperatures that can even facilitate fire on the board)

6.Long Service Life

The type of finish used in the manufacture of a printed circuit board determines the shelf life of aboard in months. Depending on the type of finish used, a printed circuit board will last 6, 12, or even more than a year. Unlike other surface finishes used in the manufacture of printed circuit boards, most printed circuit board manufacturers mainly prefer to use ENIG PCB finishes.

The reason is that such finishes come with the promise of a long shelf life that lasts up to 12 months or more. For instance, it is a fact that immersion gold finishes last longer compared to other types of finishes, such as OSP, Electro-silver, and Immersion tin, that last for six months on average.

(PCBS with immersion gold finishes will last for years as opposed to other PCBs)

Special Offer: $1 for 5 PCB Assemblies!

Please email [email protected] for details.

7.Suitable for untreated Surfaces

As a designer dealing with PCBs' manufacture, you have to ensure that you protect the untreated surfaces that oxidize immediately when left untreated. While such an exercise may seem easy, in the end, you may find out that such is not the case based on the surface finish that you choose to use. Besides several advantages associated with ENIG, its suitability across untreated surfaces such as contact points and membrane switches, makes it ideal compared to other finishes.

(With ENIG on PCB, it is easy to take care of untreated surfaces on your board)

8.Lead-free

Regular exposure to high lead levels may bring about several complications such as brain and kidney damage, body weakness, and anemia. High levels of exposure may also lead to death. Another significant advantage associated with immersion gold or ENIG is that it is lead-free, meaning that manufacturers are not exposed to harmful chemicals when using it as a surface finish on PCBs.

(Any ENIG PCB assures its users of lead-free components on its surface)

9.Suitable for PTH

PTH or Plated Through-Hole parts have leads or wires that come out of the bottom or sides, allowing a designer to stick them into a breadboard or effectively sell them into a circuit. Another notable advantage that comes with ENIG is the fact that it’s perfectly suitable for PTH. Unlike HASL finish and OPS, ENIG is the best for matters to do with PTH.

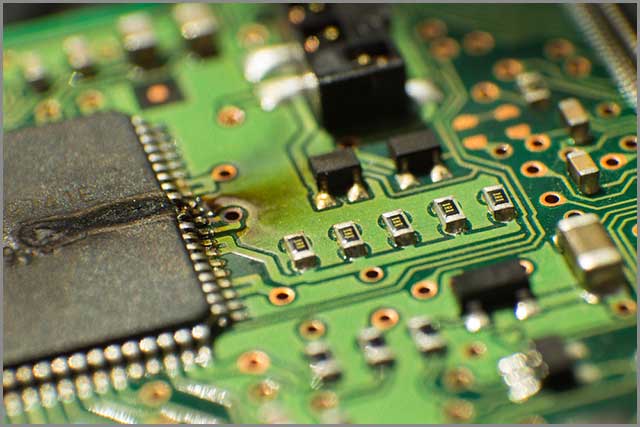

(immersion gold PCBs have effortless workability with Plated Through-Hole parts)

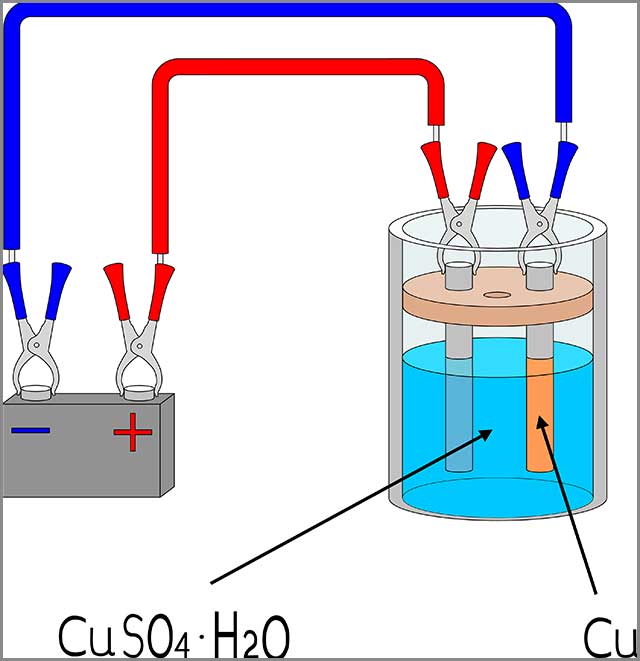

10.ENIG does not Require Electroplating

ENIG is best known for being corrosion-resistant, and a common type of plating commonly used when it comes to the manufacture of printed circuit boards. As mentioned earlier, ENIG consists of a gold layer on top of a nickel layer.

Unlike conventional electroless Nickel, ENIG plating doesn’t require an external source of power to deposit metallic coatings on the base material, but only applied through some chemical reaction.

(ENIG plating doesn’t need an external source of energy to deposit metallic layers on the base material)

11.Easy to Weld

Based on different crystal structures that get formed by both Gold plating and ENIG, as a designer, you’ll find out that ENIG is easy to weld. Additionally, welding ENIG does not bring about welding defects based on the fact that ENIG is a bit softer than Gold plating.

It is easy to control the stress in immersion gold as opposed to Gold plating. Unlike HASL or ENEPIG solutions that pose a significant challenge when welding, such is not the case with ENIG.

(A designer welding an ENIG plated PCB)

12.ENIG Meets all RoHS Requirements

Restrictions of Hazardous Substances (RoHS) is a directive that prohibits the usage of 10 most poisonous substances when manufacturing electric and electronic devices.

Some banned substances include Mercury, Lead, Cadmium, Dibutyl phthalate, Polybrominated Diphenyl ether, and Hexavalent chromium, to mention but a few. On the bright side is that ENIG meets the entire RoHS requirements, which is a good reason why PCB designers use it on a large scale.

(ENIG PCBs should meet all the RoHS requirements for usage)

13. ENIG PCB Finds use in a variety of Electronic Products

Last but not least, another notable advantage associated with ENIG (Electroless Nickel Immersion Gold) surface coating is that it finds much use in a variety of electronic products from computer motherboards to wearables, and medical appliances, among others.

Unlike other types of solutions that may fail to function as desired across several electronic products, something good about ENIG PCB is that it can perfectly fit across various electronic products with much ease.

(ENIG PCB finds use in the everyday products that we use daily)

Summary

Are you in the market for the best surface finish for your next PCB assembly project? We at OurPCB would appreciate the chance to have an in-depth discussion with you. OurPCB is your reliable partner for your entire PCB needs. We are flexible, trustworthy, and highly dependable for even some of your most complex requests and needs.

We are industry experts when it comes to PCB surface finishes. Call us now for assistance in choosing the right surface finish for your PCB assembly. We are here for you.

Special Offer: $1 for 5 PCB Assemblies!

Please email [email protected] for details.